Automatic charging machine for smelting furnace

A technology of automatic feeder and furnace, which is applied to furnaces, crucible furnaces, furnace types, etc., can solve the problems of uneven feeding time interval, unable to meet production requirements, and no copper plate cleaning work, so as to achieve uniform feeding and save feeding time. , The effect of convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

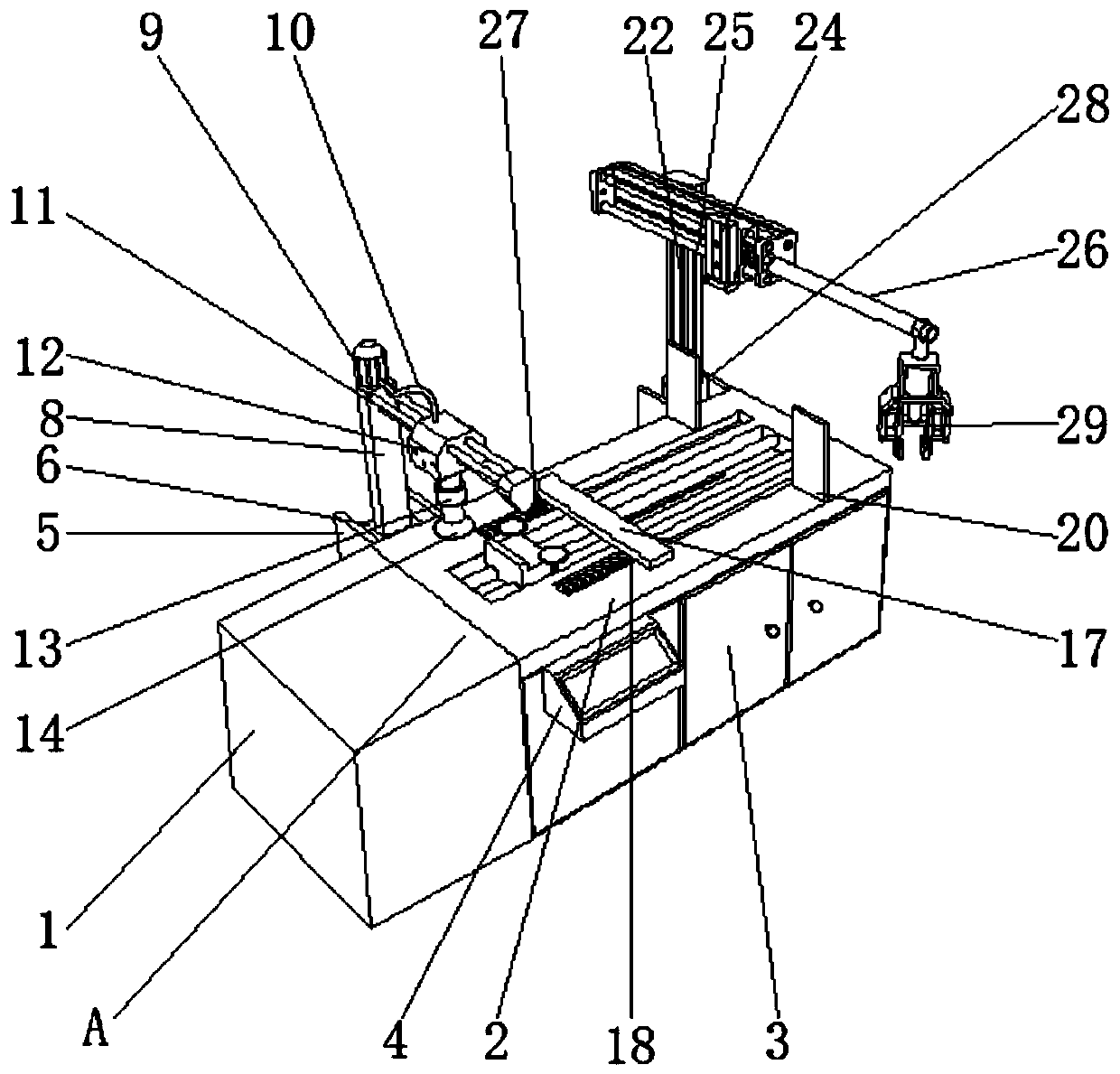

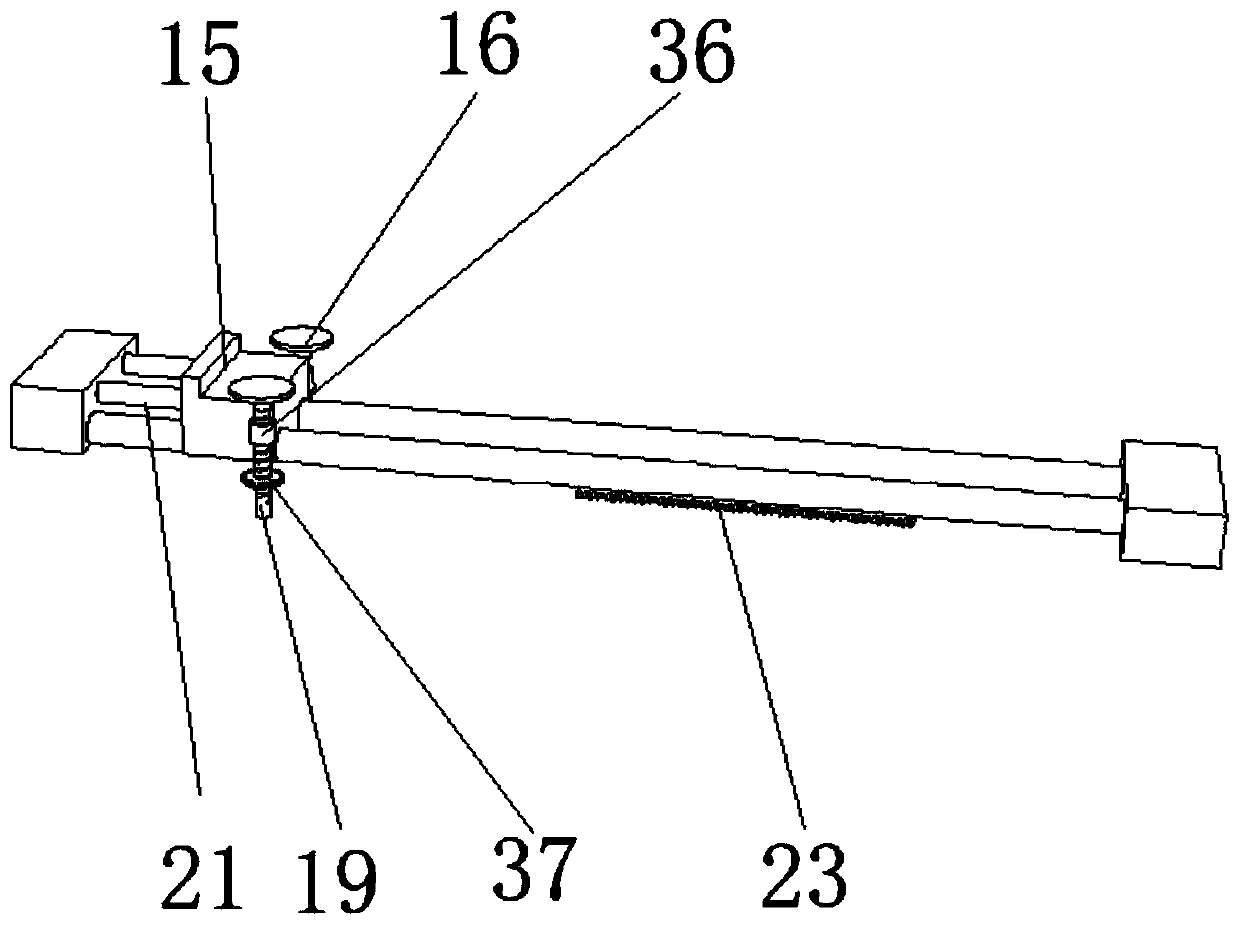

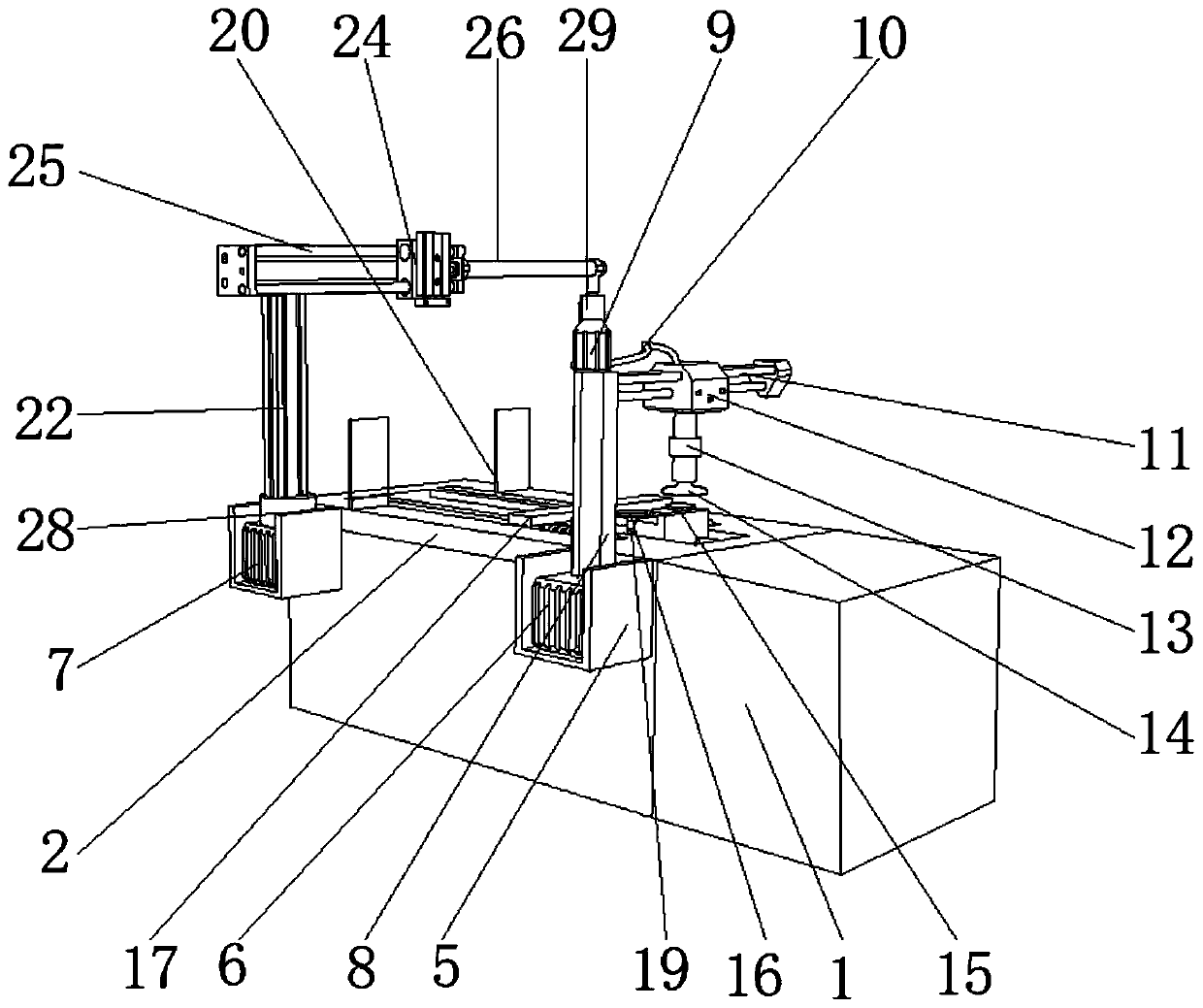

[0023] refer to Figure 1-4 , an automatic feeding machine for a melting furnace, comprising a workbench 2, a placement box 1, a suction cup splitting device, a feeding device and a clamping device, the placement box 1 is located on the side of the workbench 2, the suction cup splitting device is located above the placement box, and the workbench 2 There is a groove on one side of the top, the feeding device is set in the groove, the clamping device is located on the other side of the workbench, the bottom of the workbench 2 is fixedly connected to the distribution box 3, and the outer wall of the distribution box 3 is fixedly connected to a U Type load-bearing plate 5, the other side outer wall of distribution box 3 is fixedly connected with control box 4.

[0024] The sucker slicing device includes a first rotating motor 6, a rotating column 8, an air pump 9, and a suction cup 14. The first rotating motor 6 is fixedly connected to the bearing plate 5, and one side of the out...

Embodiment 2

[0031] In the actual smelting and casting production process, the copper plate is melted and refined in a high-temperature melting furnace, and then enters the holding furnace through the submerged flow channel for heat preservation, and then crystallizes and cools through the crystallizer, and is pulled horizontally or upward by the tractor to continuously cast the billet.

[0032] In order to further control the liquid level of the copper liquid in the holding furnace to remain basically unchanged, the present embodiment 2 can also feed back the real-time casting speed to the PLC controller, and adjust the feeding speed according to the real-time casting speed, so that the copper liquid in the holding furnace remains basically the same. The liquid level and the same temperature make the product quality relatively stable, and the casting speed can be calculated according to the traction speed of the tractor.

Embodiment 3

[0034] refer to Figure 5 , an automatic feeding machine for a melting furnace, comprising a stepper motor 30 fixed to the outer wall of one side of the storage box 1 by bolts, and a first gear 32 plugged into the output end of the stepping motor 30, and a support plate 34 welded on the inner wall of the bottom of the storage box 1, And support plate 34 one side is plugged with second gear 33, second gear 33 one side is fixed with expansion plate 35 by bolt, and expansion plate 35 top is fixed with support plate 34 by bolt, puts box 1 top and is fixed with closing plate by bolt. and a sealing cover is welded on one side of the hinge, and a vacuum machine is fixed on one side of the storage box 1 by bolts, and vacuum cleaning it can improve the quality of the copper liquid and the quality of the product.

[0035] The working process of this embodiment is as follows: when in use, when the copper plate needs to be cleaned and treated with water, the stepper motor 30 is started to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com