Absolute inspection method for synchronous measurement of multiple spherical standard lenses

A technology of simultaneous measurement and inspection methods, applied in the field of optical interferometry, to achieve the effects of simple structure, simple measurement process and low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

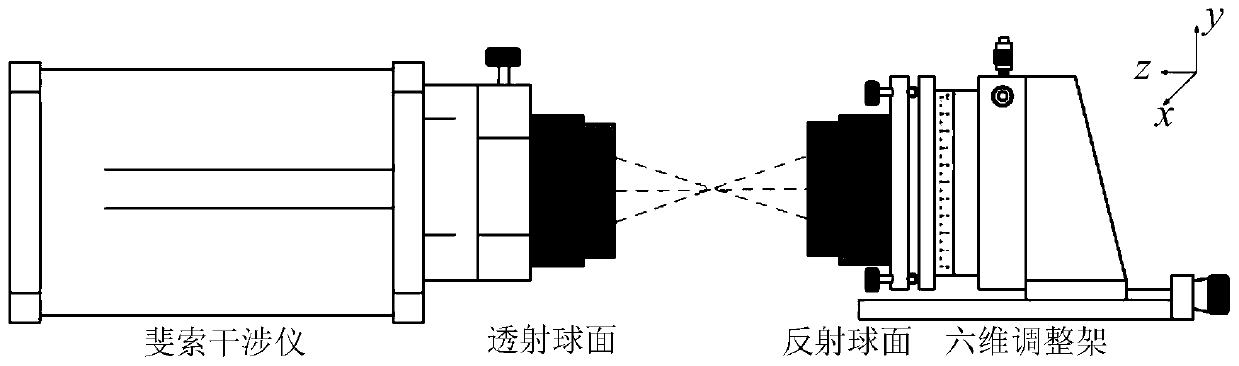

[0068] combine figure 1 , all measurement processes in the present invention are in figure 1 in the specified coordinate system shown. Based on the test surface, establish a coordinate system, take the opposite direction of the optical axis of the Fizeau type laser interferometer as the z-axis, and the vertical upward direction as the y-axis, and the x-axis, y-axis, and z-axis can form a thumb along the optical axis. A right-handed coordinate system in the opposite direction.

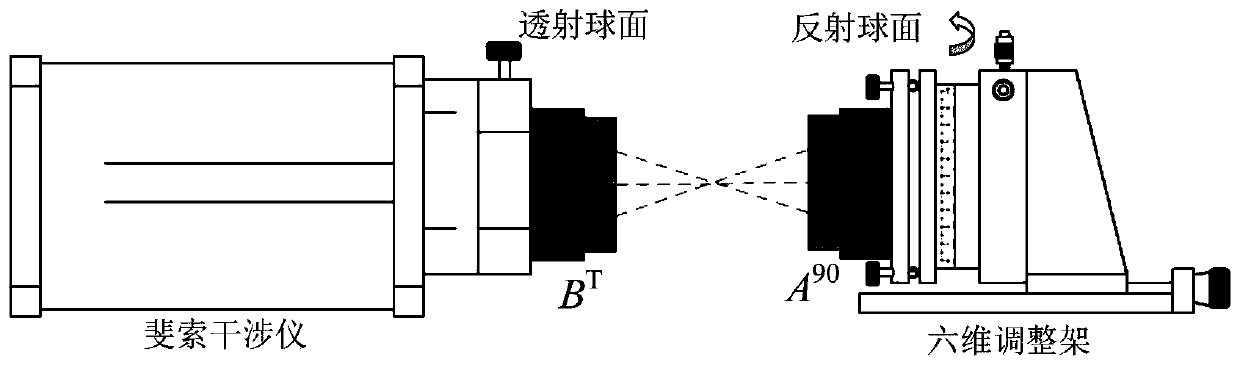

[0069] combine Figure 2 to Figure 5 , the absolute inspection method of a plurality of spherical standard lens synchronous measurements of the present invention, comprises the following steps:

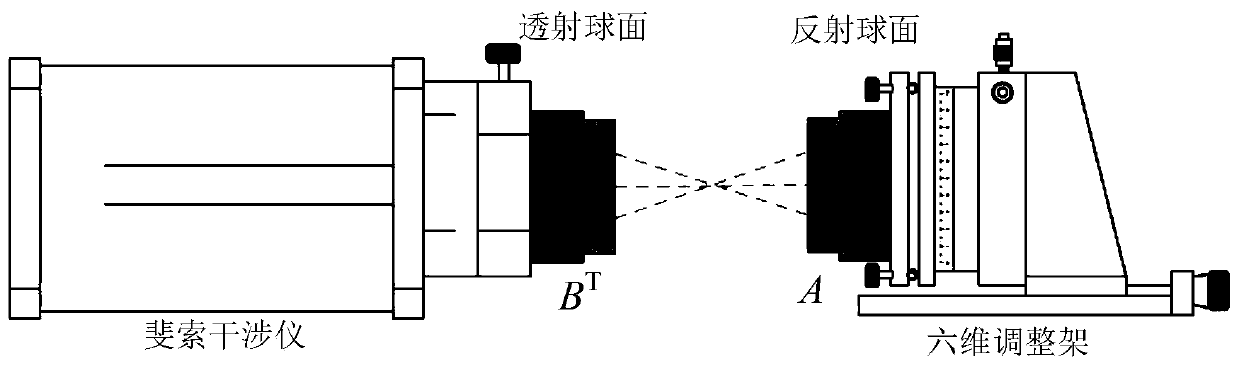

[0070] Step 1, such as figure 2 As shown, the Fizeau-type laser interferometer is used to perform an interferometric measurement on the spherical surface B as the reference surface and the spherical surface A as the test surface, and the measurement result M 1 , the formula is as follows:

[0071] m 1 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com