Method for repairing fine line

A repair method and fine circuit technology, applied in printed circuit repair/correction, printed circuit, printed circuit, etc., can solve problems such as easy deformation and difficult circuit defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

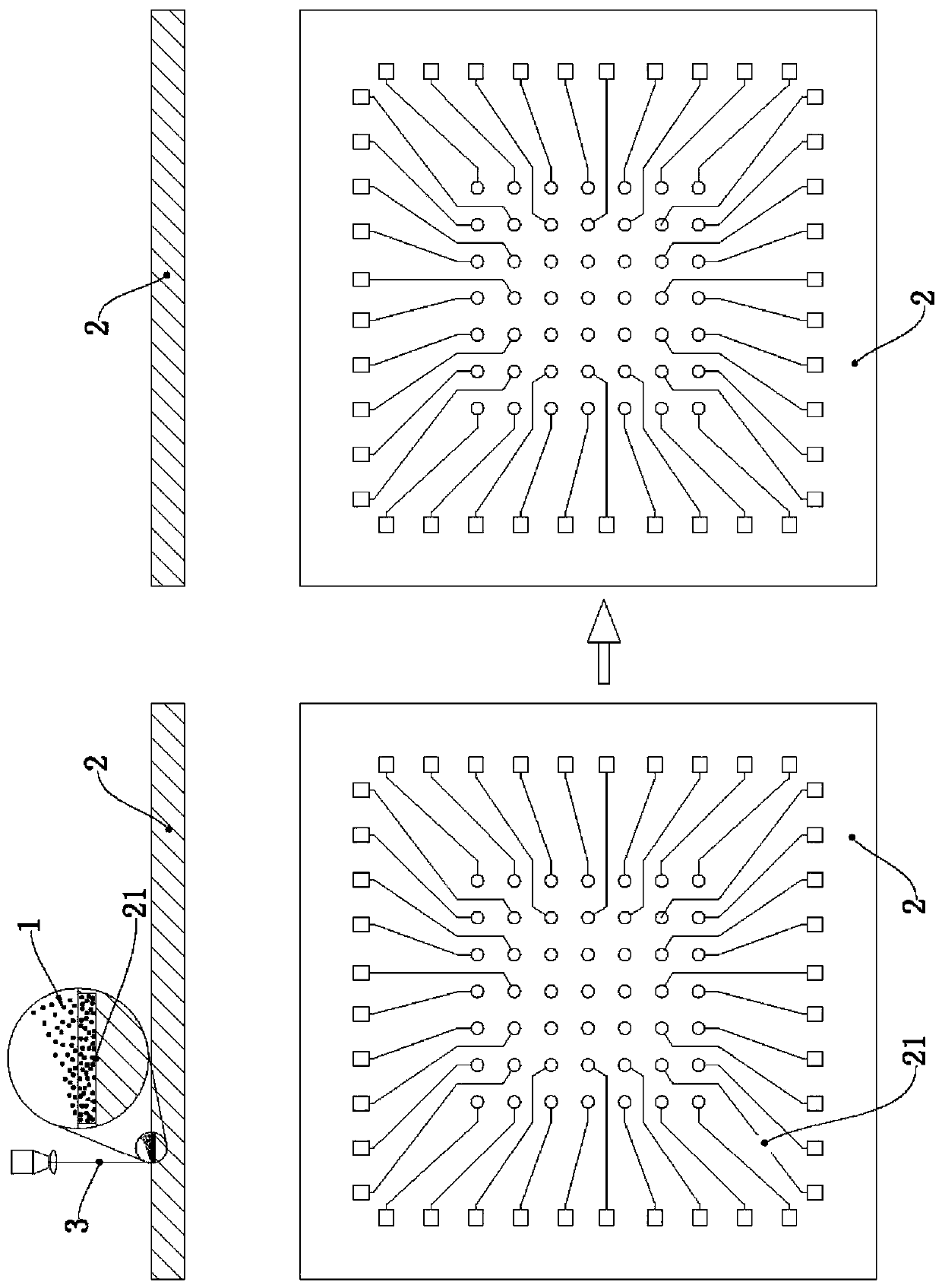

Embodiment 1

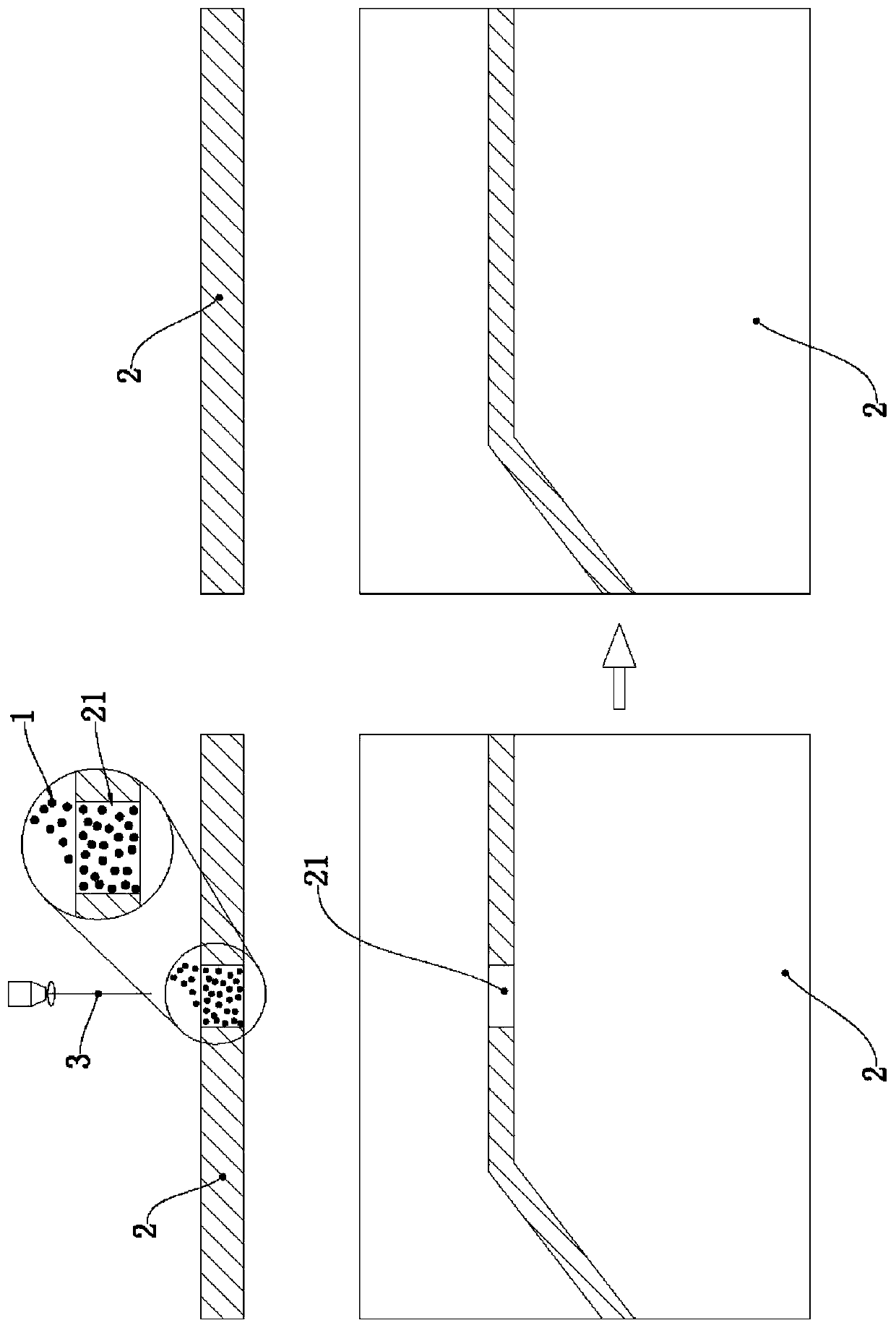

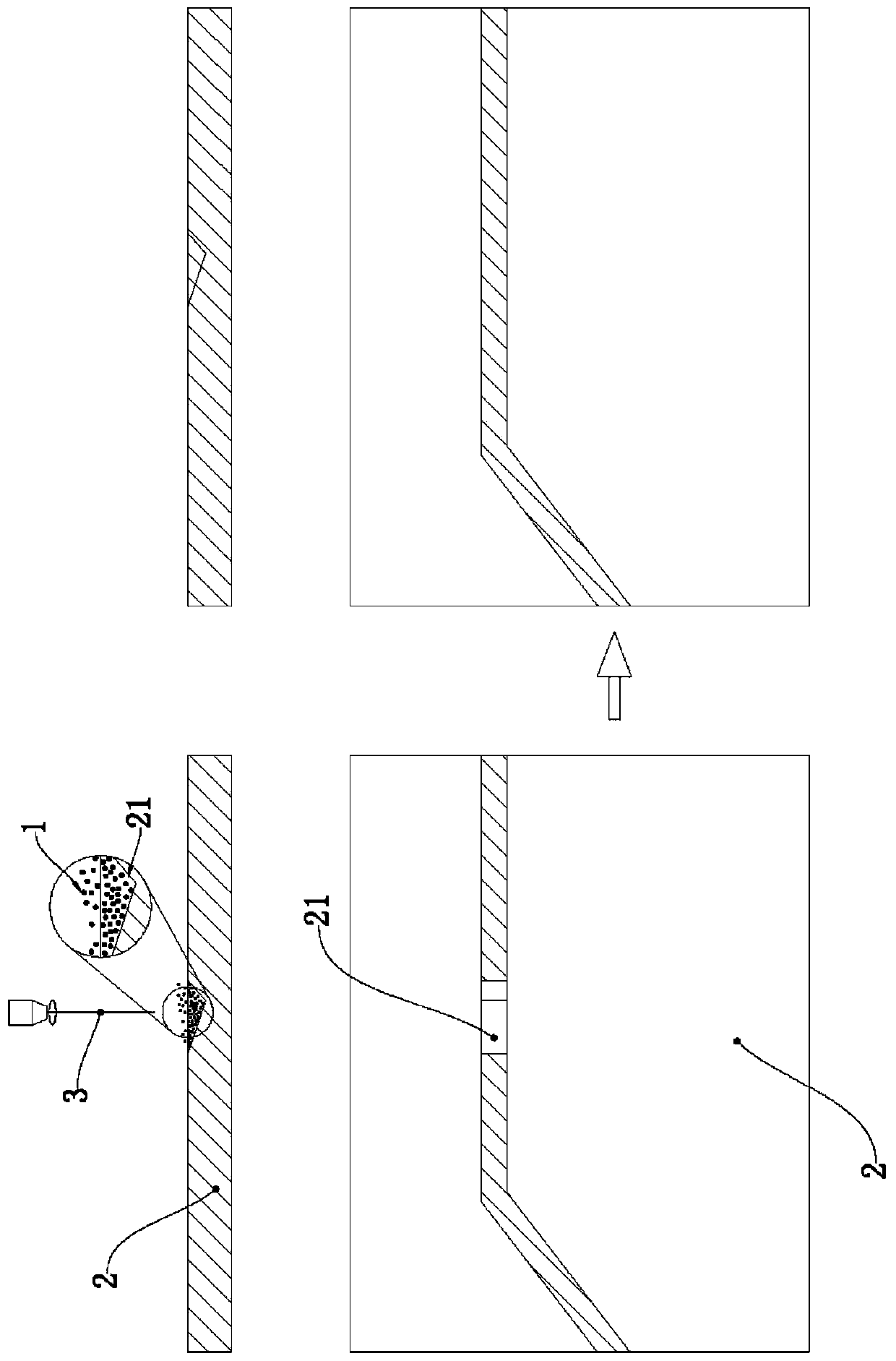

[0051] Add polyvinylpyrrolidone-coated nano-copper particles 1 with a particle size of 50nm to ethylene glycol to form a copper paste with a solid content of 80%, and drop it to a defect position 21 of a 8x8mm rewiring layer through a nozzle. The nano-copper on the line defect position 21 is irradiated by the laser 3 of appropriate wavelength and energy, and the nano-copper particle 1 melts at a relatively low temperature and fills up the line defect. After the laser 3 is removed, a conductive path is formed at the defect position, and after cleaning, the repair of the circuit defect is completed.

Embodiment 2

[0053] The imidazole-coated nano-copper particles 1 with a particle size of 100nm were added to ethylene glycol to form a copper paste with a solid content of 85%, which was dropped onto the circuit defect position 21 of the PCB board through a nozzle. The nano-copper on the line defect position 21 is irradiated by the laser 3 of appropriate wavelength and energy, and the nano-copper particle 1 melts at a relatively low temperature and fills up the line defect. After the laser 3 is removed, a conductive path is formed at the defect position, and after cleaning, the repair of the circuit defect is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com