Evaporative cooling type grain cooling machine

An evaporative cooling and cooling machine technology, used in refrigerators, preservation of seeds by freezing/cooling, compressors, etc., can solve the problems of poor air-cooling cooling effect, inconvenient operation, high condensation temperature, and achieve high heat exchange effect. , Improve the COP value, the effect of low condensation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

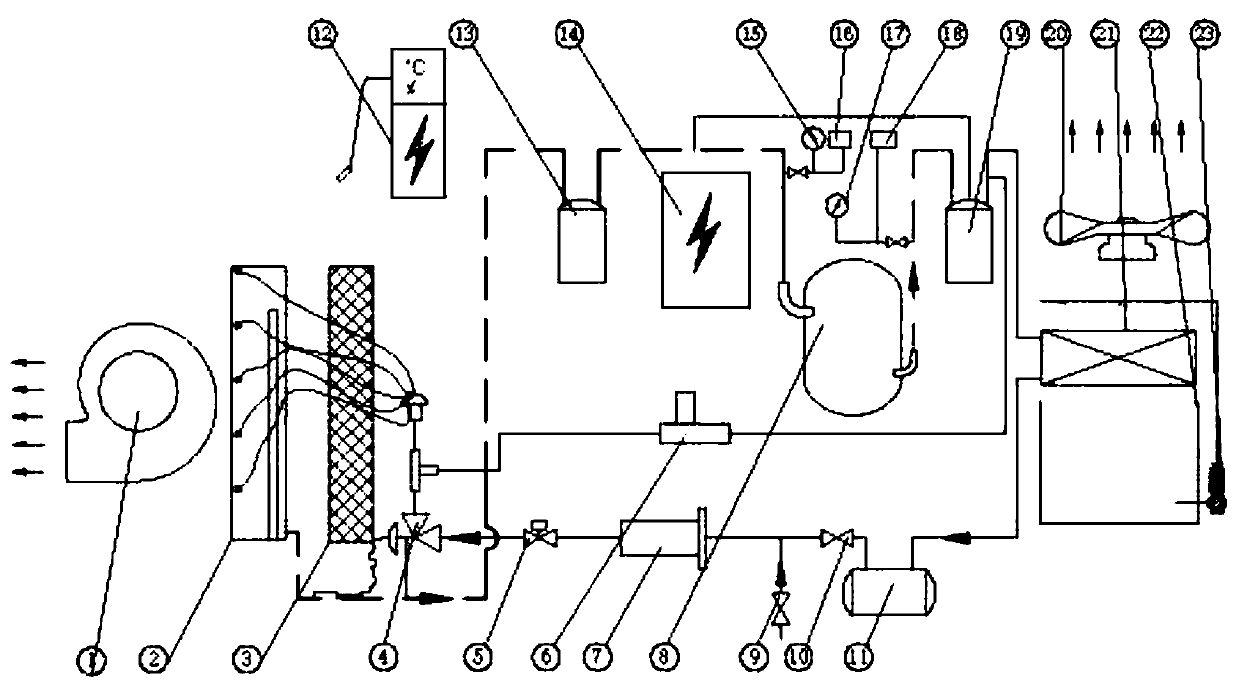

[0026] An evaporative cooling grain cooler, comprising an evaporating section and a compression condensing section, one end of the finned evaporator 2 in the evaporating section is connected to the evaporative cooling condenser 21 in the condensing section, the finned The other end of the evaporator 2 is connected to the gas-liquid separator 13 in the compression and condensation section through the air return pipeline, and an energy conditioner 6 is also arranged between the evaporation section and the compression and condensation section.

Embodiment 2

[0028] An evaporative cooling grain cooler, comprising an evaporating section and a compression condensing section, one end of the finned evaporator 2 in the evaporating section is connected to the evaporative cooling condenser 21 in the condensing section, the finned The other end of the evaporator 2 is connected to the gas-liquid separator 13 in the compression and condensation section through the air return pipeline, and an energy conditioner 6 is also arranged between the evaporation section and the compression and condensation section.

[0029] The compression and condensation section includes a compressor 8 , an oil separator 19 , an evaporative condenser 21 , a liquid receiver 11 , a dry filter 7 , a solenoid valve 5 , an expansion valve 4 and a gas-liquid separator 13 connected in series.

[0030] One end of the energy conditioner 6 is arranged on the pipeline between the oil separator 19 and the evaporative condenser 21 , and the other end of the energy conditioner 6 i...

Embodiment 3

[0032] An evaporative cooling grain cooler, comprising an evaporating section and a compression condensing section, one end of the finned evaporator 2 in the evaporating section is connected to the evaporative cooling condenser 21 in the condensing section, the finned The other end of the evaporator 2 is connected to the gas-liquid separator 13 in the compression condensation section through the air return pipeline, and an energy conditioner 6 is also arranged between the evaporation section and the compression condensation section, and one end of the energy conditioner 6 The other end of the energy conditioner 6 is arranged between the expansion valve 4 and the finned evaporator 2 .

[0033] The compression and condensation section includes a compressor 8 , an oil separator 19 , an evaporative condenser 21 , a liquid receiver 11 , a dry filter 7 , a solenoid valve 5 , an expansion valve 4 and a gas-liquid separator 13 connected in series.

[0034] An air filter 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com