Method for calculating flow matching between threshing and redrying processes

A technology of flow matching and calculation method, applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems of poor process flow matching, large dependence and restriction, large flow fluctuation, etc., to reduce the frequency of shutdown and material interruption, Improve matching and stability, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

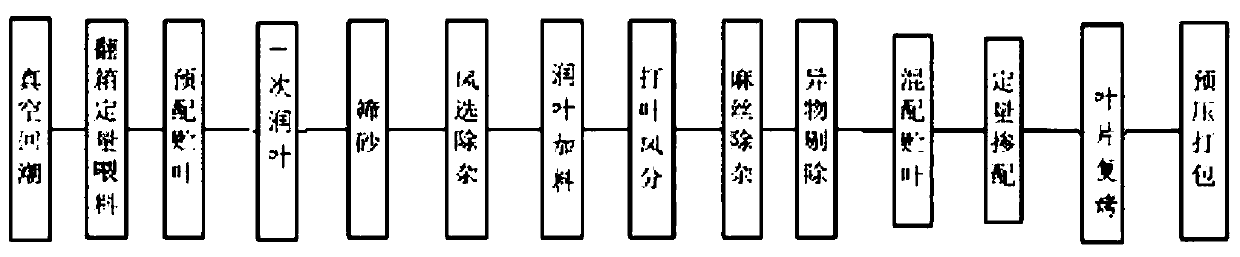

Method used

Image

Examples

Embodiment 2

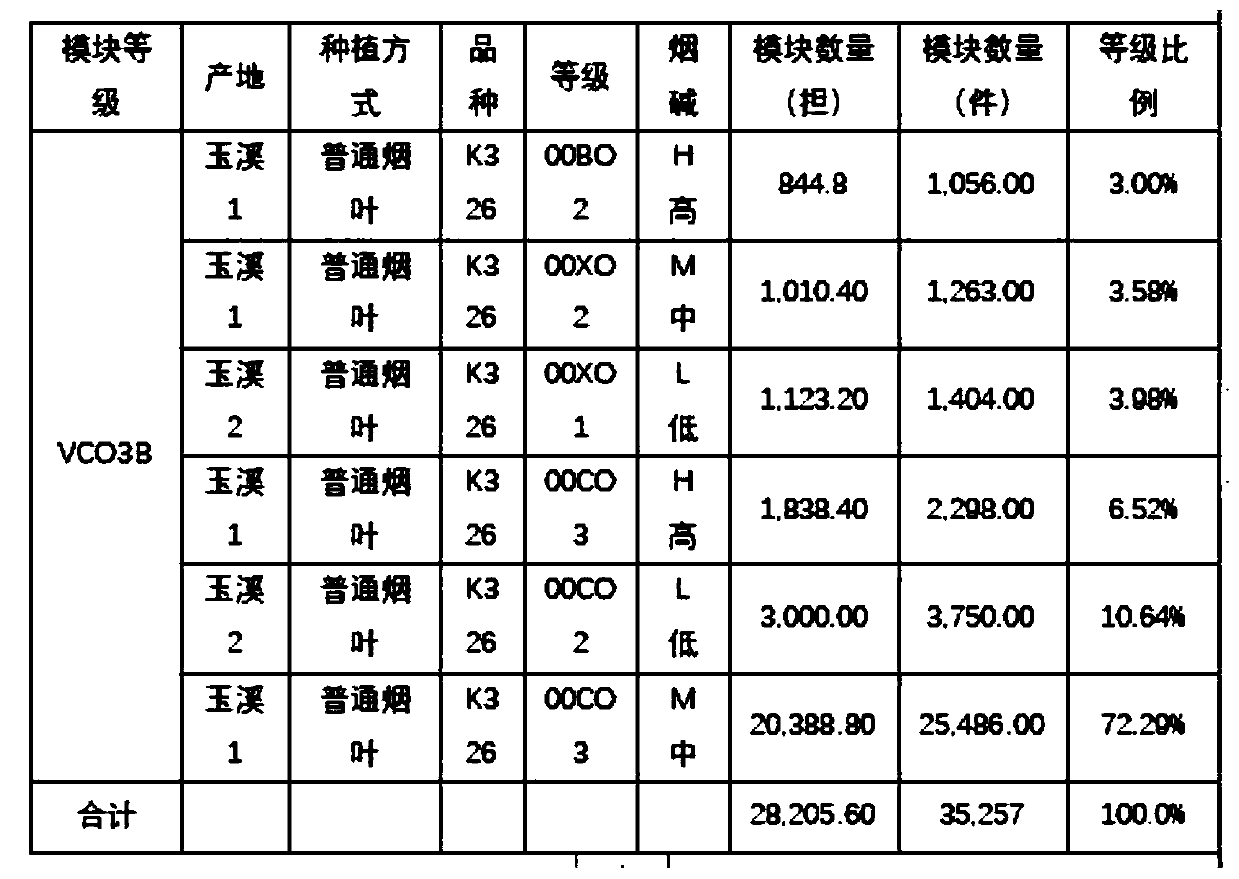

[0033] Example 2: Let's take the 2018 season VCO3B module tobacco leaves as an example, as figure 2 Shown is the recipe sheet for this module.

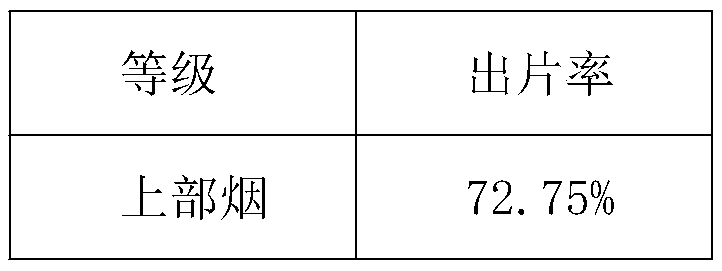

[0034] It can be seen from the figure that the proportion of smoke in the upper part of the module is 3.00%, the proportion of smoke in the lower part is 7.56%, and the proportion of smoke in the middle part is 89.45%. In addition, the production rate of different parts of tobacco leaves in the 2018 roasting season is calculated as shown in the table below.

[0035]

[0036]

[0037] According to the proportion of tobacco leaves in different parts of the formula sheet and the production rate of tobacco leaves in different parts, the production rate of VCO3B module tobacco leaves can be calculated as 66.93% according to the calculation formula of the production rate.

[0038] Finally, the average moisture content of the VCO3B module tobacco leaves in the 2018 curing season was 15.45%, 17.29% and 18.37%, respectively.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com