Supercritical fluid extraction system and extraction method

A supercritical fluid and extraction technology, applied in the field of extraction, can solve the problems of inability to extract raw materials, insufficient extraction of raw materials, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

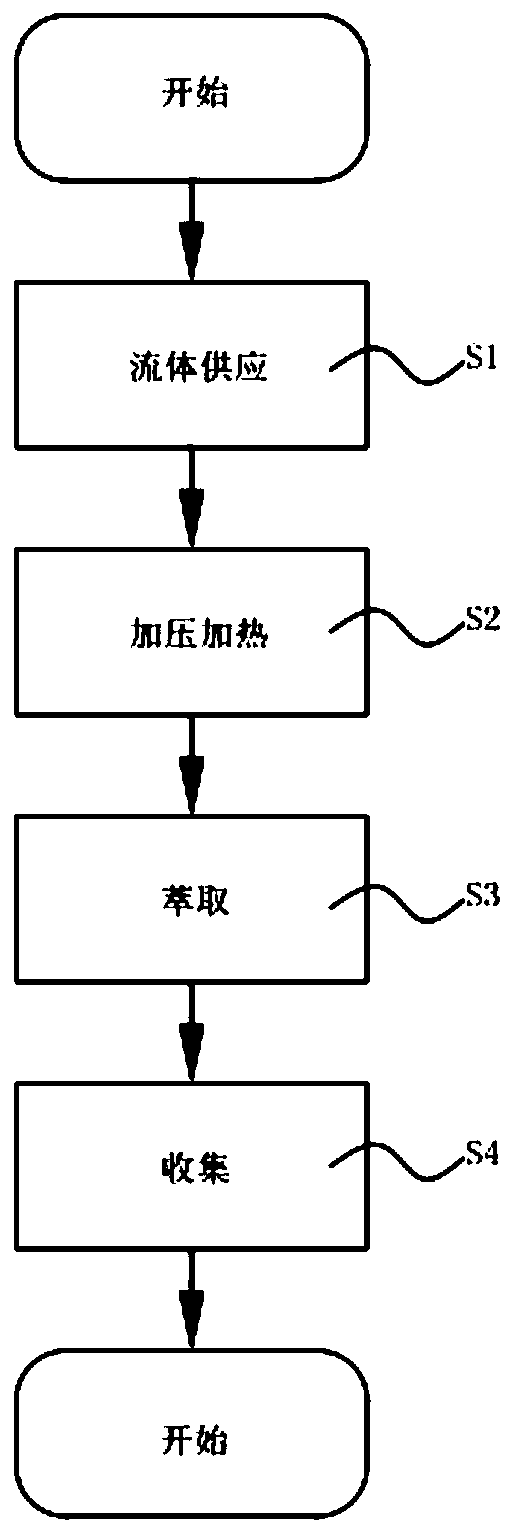

Method used

Image

Examples

Embodiment 1

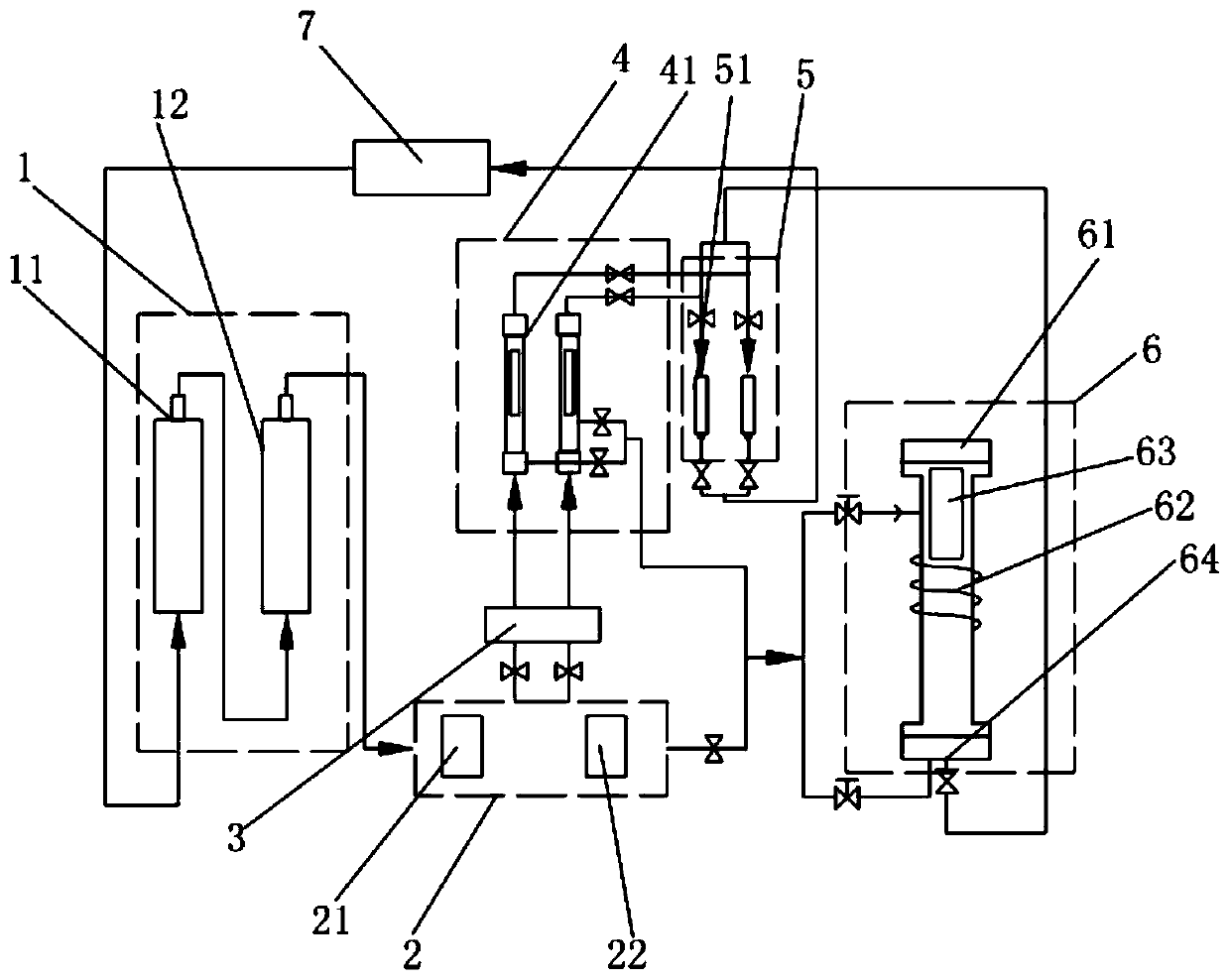

[0052] Extraction of polysaccharides and triterpenes from Cinnamomum camphorii using supercritical carbon dioxide, such as figure 1 , Figure 3-5 As shown, the fluid supply device 1 at least has a fluid storage tank 11 and a circulation cooling tank 12 communicated with the fluid storage tank 11 through pipelines; the fluid storage tank 11 stores carbon dioxide, and the carbon dioxide is passed into the circulation cooling tank through pipelines 12 for cooling, the cooled carbon dioxide is passed into the pressurizing device 2 through the pipeline, and the pressurizing device 2 is connected with the circulating cooling tank 12 through the pipeline, and the control fluid output control valve is arranged on the pipeline, and the pressurizing device 2 At least one booster pump 21 is provided. The booster pump 21 pressurizes the carbon dioxide to the pressure required for extraction, and pressurizes the modified booster pump 22 again, with a pressure value of 2000psi, which acts a...

Embodiment 2

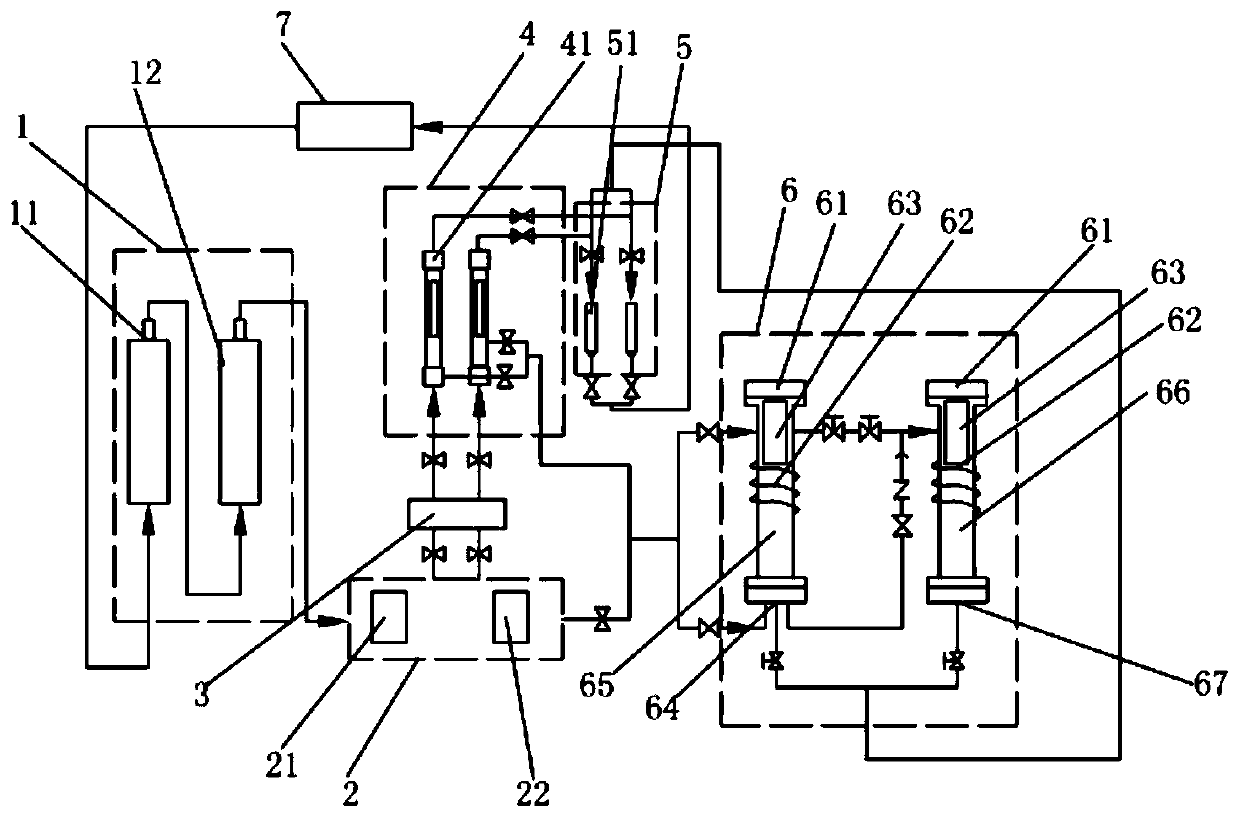

[0057] Using supercritical carbon dioxide to extract triterpenes and polysaccharides from Bailing mushroom, such as figure 2 , 6 and Figure 3-4 As shown, the fluid supply device 1 at least has a fluid storage tank 11 and a circulation cooling tank 12 communicated with the fluid storage tank 11 through pipelines; the fluid storage tank 11 stores carbon dioxide, and the carbon dioxide is passed into the circulation cooling tank through pipelines 12 for cooling, the cooled carbon dioxide is passed into the pressurizing device 2 through the pipeline, and the pressurizing device 2 is connected with the circulating cooling tank 12 through the pipeline, and the control fluid output control valve is arranged on the pipeline, and the pressurizing device 2 At least one booster pump 21 is provided. The booster pump 21 pressurizes the carbon dioxide to the pressure required for extraction, and pressurizes the modified booster pump 22 again, with a pressure value of 2000psi, which acts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com