Residue pre-cleaning device for processing net ropes

A pre-cleaning and residue technology, applied in the cleaning method using liquid, dry gas arrangement, lighting and heating equipment, etc., can solve the problems of thin wire entanglement, blowing and absorption, poor cleaning effect, etc., to improve the rational use and convenience Collect and process, improve the effect of pre-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

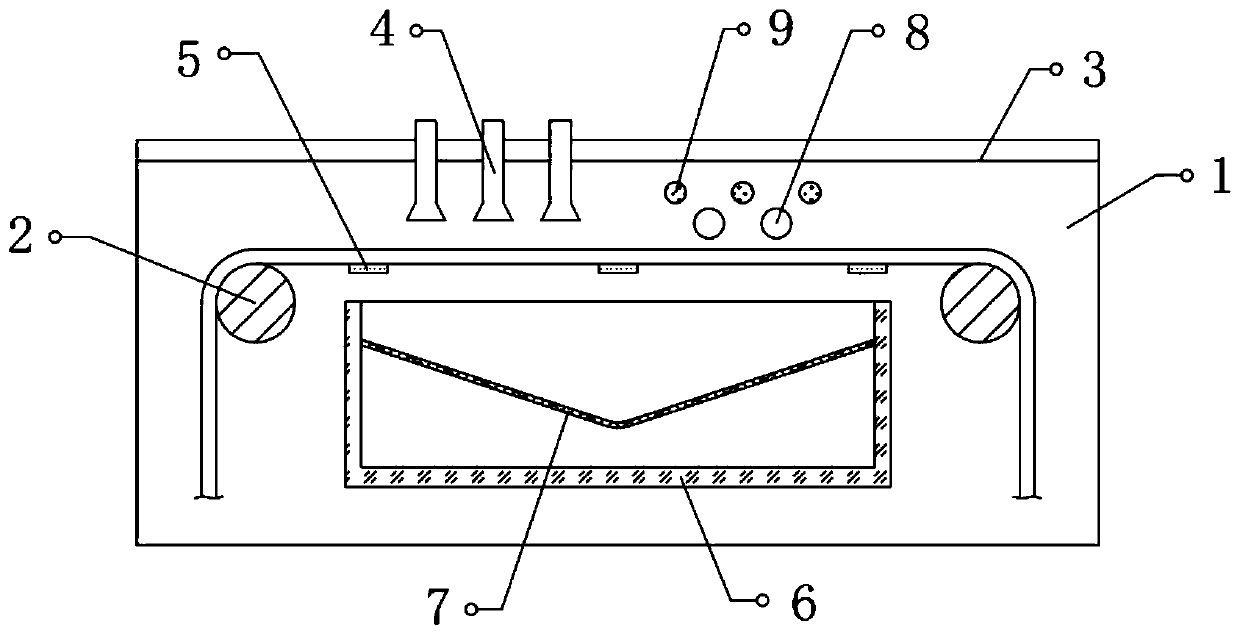

[0023] refer to figure 1 , a residue pre-cleaning device for net rope processing, comprising a fixed frame 1, both sides between the inner walls at both ends of the fixed frame 1 are rotatably connected with support rollers 2, and the top of the support roller 2 is rotatably connected with ropes, and the fixed frame 1 The top of the rope between the inner walls at both ends is fixed with a fixed plate 3, and one side of the outer wall at the bottom of the fixed plate 3 is fixed with a plurality of nozzles 4, and the top of the nozzles 4 is connected with a water supply mechanism through a water pipe, and the inner walls at both ends of the fixed frame 1 Vents 8 are provided on the side away from the nozzle 4, and the inner wall at both ends of the fixing frame 1 is located below the rope and is fixed with a vibrating piece 5 by a torsion spring, and the top of the vibrating piece 5 is in contact with the bottom of the rope.

[0024] In the present invention, a collection box 6...

Embodiment 2

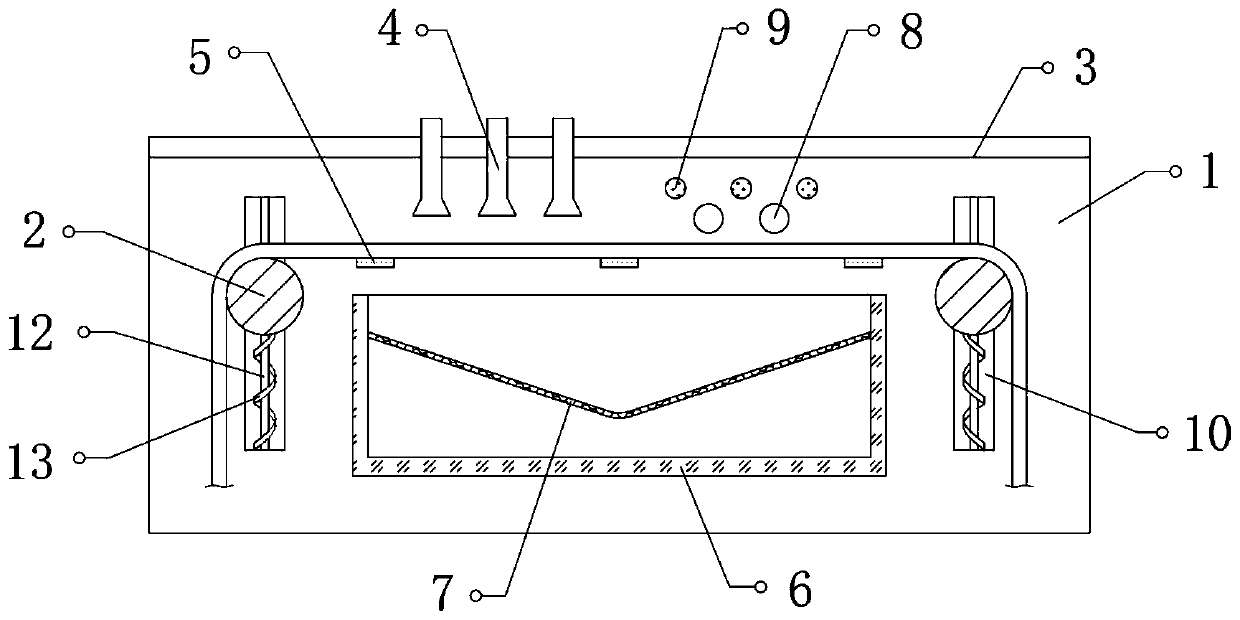

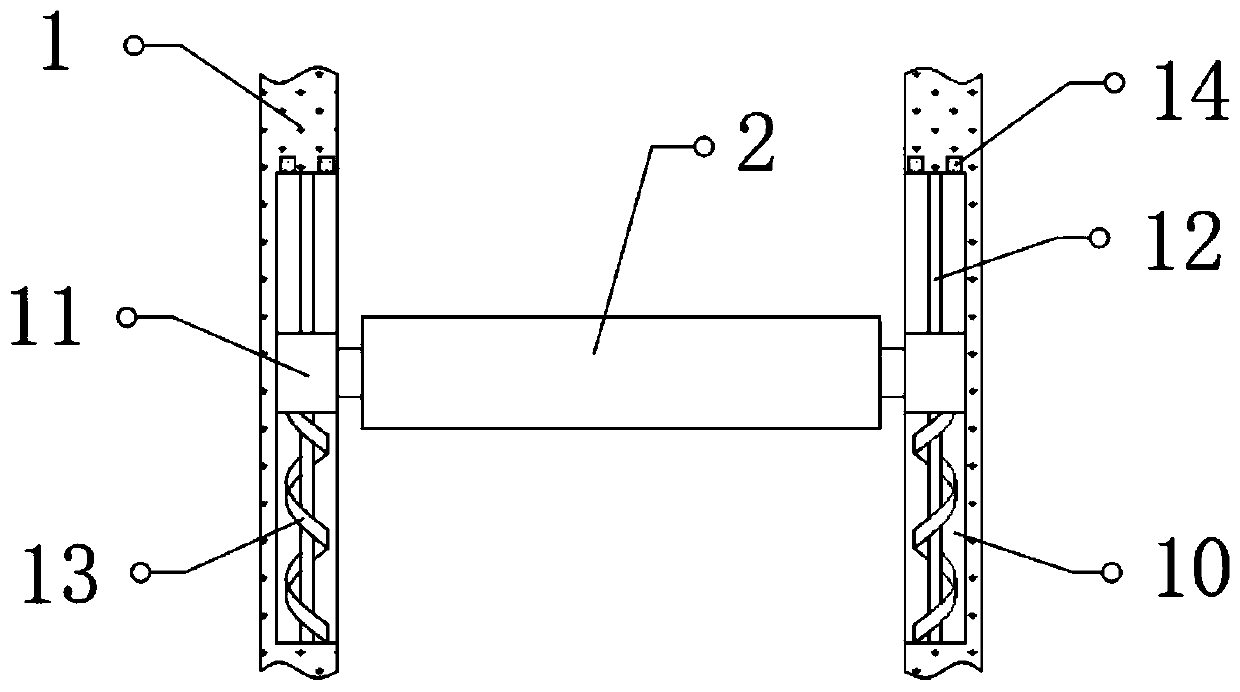

[0028] refer to Figure 2-3 , a residue pre-cleaning device for net rope processing, a connecting groove 10 is provided at the position corresponding to the inner wall of the two ends of the fixed frame 1 and the supporting roller 2, and the inner wall of the connecting groove 10 is slidably connected with a connecting block 11, and the top of the connecting groove 10 and The limit bar 12 is fixed between the inner walls of the bottom, and the top of the connecting block 11 is provided with a perforation, and the inner wall of the perforation is slidingly connected with the outer wall of the limit bar 12, and the two ends of the support roller 2 are respectively connected to the two connecting blocks 11 in rotation. A spring 13 is fixed between the bottom of the connecting block 11 and the bottom inner wall of the connecting groove 10, and the spring 13 is slidably sleeved on the outside of the limit rod 12, and the top inner wall of the connecting groove 10 is fixed with an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com