Material box induction automatic control device and method of strip-shaped plasma cleaning machine

A technology of plasma cleaning machine and automatic control device, applied in the field of plasma cleaning machine, can solve problems such as operator error, product quality risk, lack of foolproof measures, etc., to simplify program calling operation steps, reduce product quality risks, and avoid mistakes Programmatically produced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Detailed specific embodiments of the present invention will be disclosed herein. It is to be understood, however, that the disclosed embodiments are merely typical examples of the invention, which may be embodied in many alternative forms. Therefore, specific structural and functional details disclosed herein are not limiting, but merely serve as a representative basis for describing various implementations to one skilled in the art in accordance with the claims.

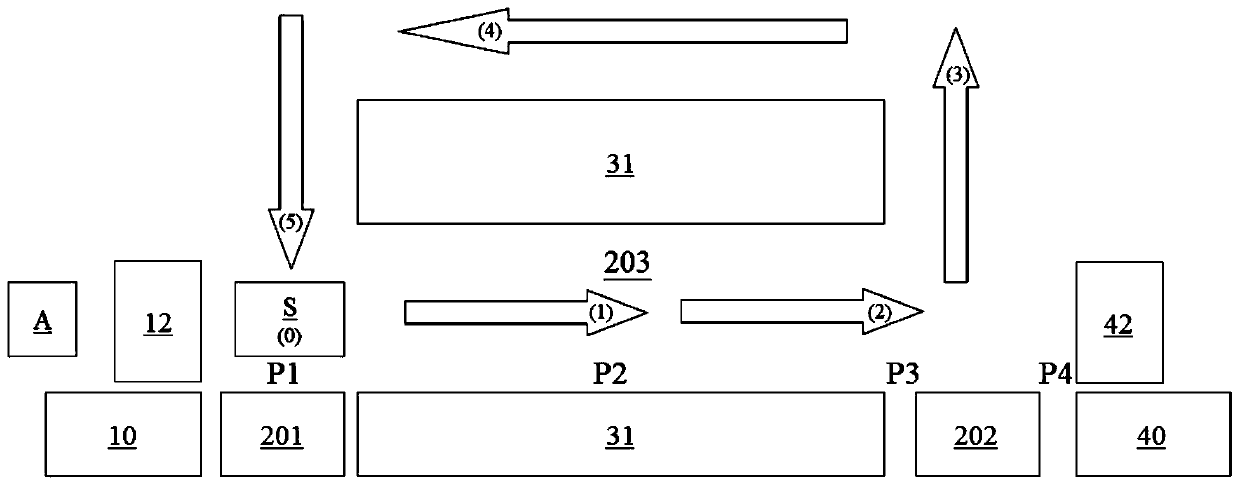

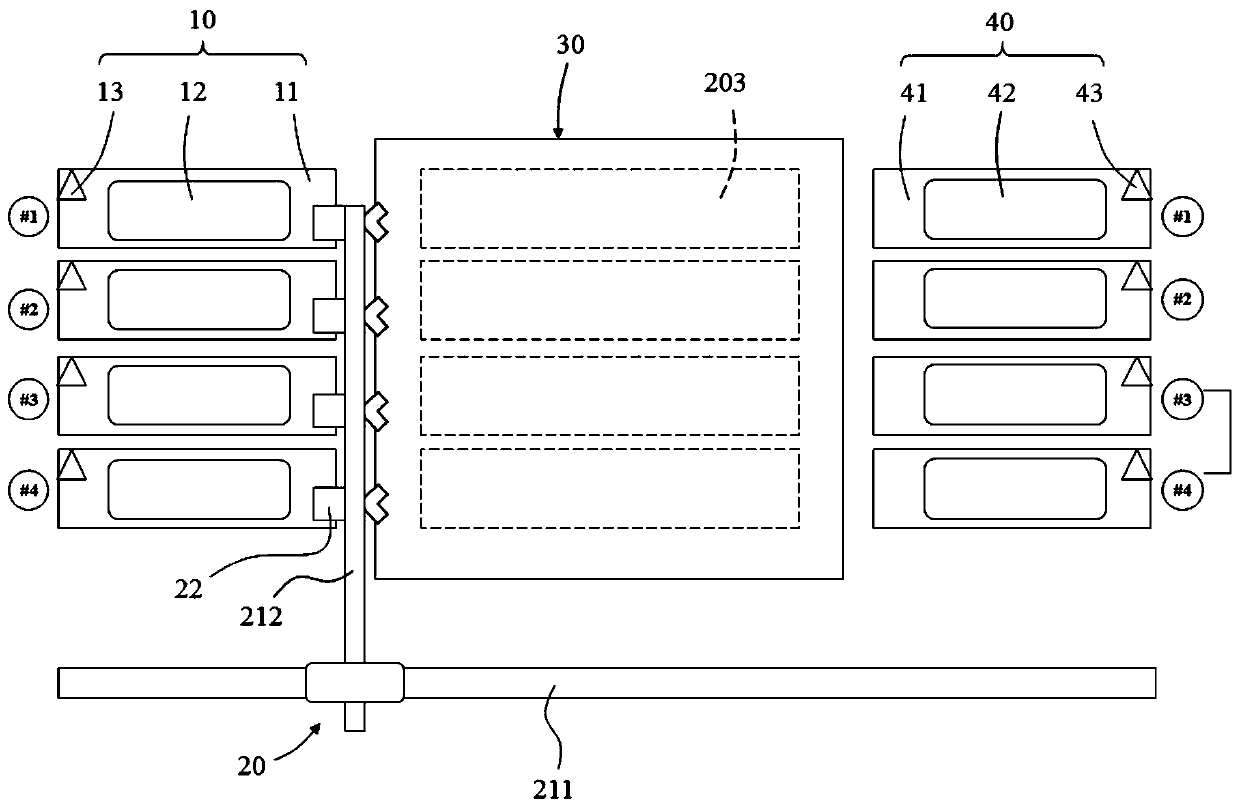

[0051] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

[0052]The plasma cleaning machine of the present invention can generate physical and chemical plasma at the same time; the standard model of the cleaning machine uses two types of plasma for cleaning, and can also use a single type for cleaning according to actual needs.

[0053] In an embodiment of the present invention, the physical plasm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com