Enclosed bus installing device and method

A technology of closed busbar and installation equipment, which is applied in the direction of fully enclosed busbar device, welding equipment, auxiliary welding equipment, etc., can solve the problems of long adjustment period, etc., and achieve the effect of convenient observation, position adjustment and simple detection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

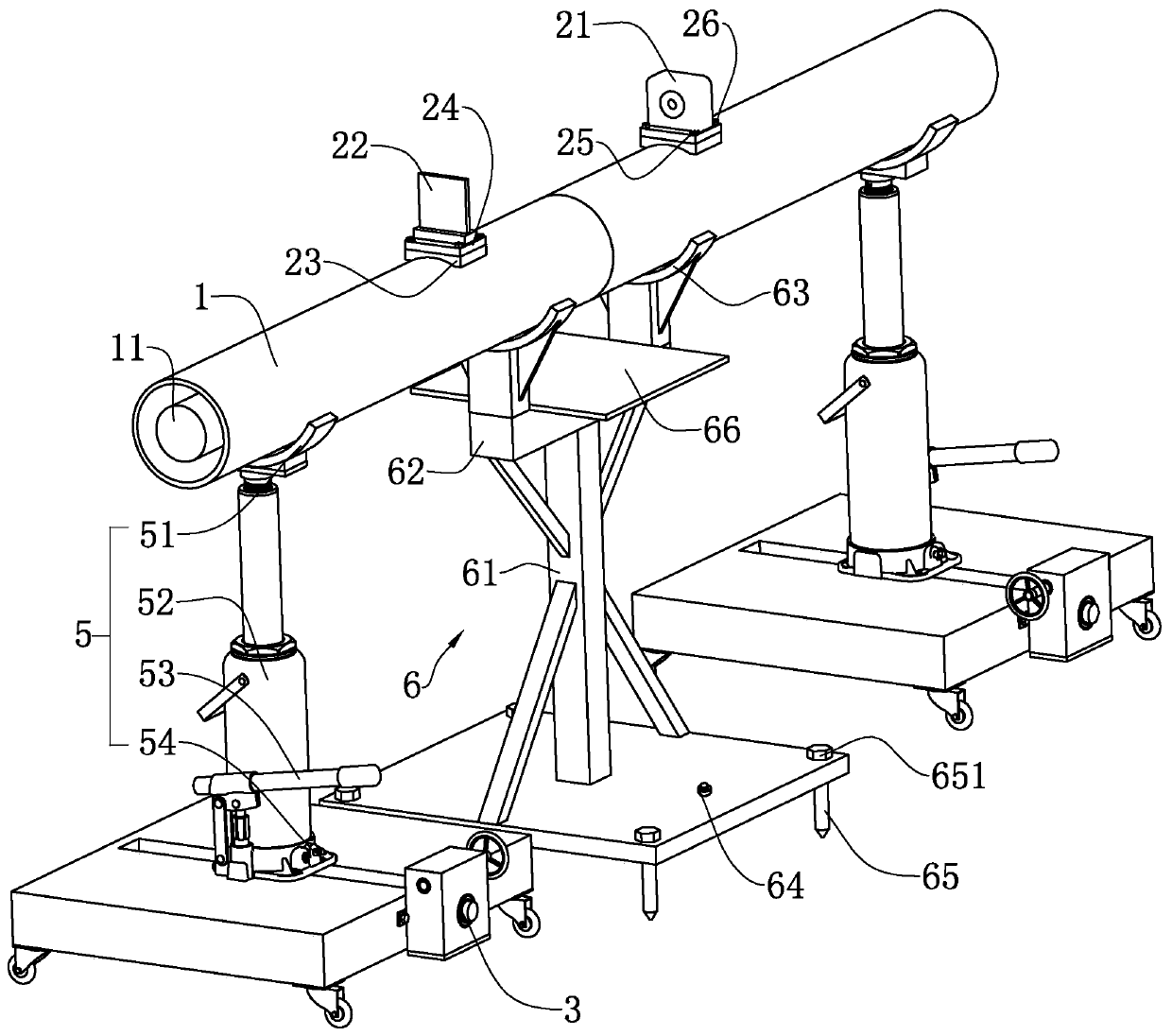

[0048] refer to figure 1 , the present invention discloses a closed busbar installation equipment, which is used for the installation of closed busbars. After aligning the two closed busbars on the ground to be in a coaxial state, the two closed busbars are welded and connected. The closed busbars include cables 11 And the shell 1 located outside the cable 11, a detection mechanism is arranged on the closed bus, the detection mechanism includes a laser light 21 detachably connected to one of the shells 1, and a reflector 22 is detachably connected to the other shell 1, and the laser light The angular relationship between the light emitted by 21 and the laser light reflected by the mirror 22 determines the coaxiality of the two housings 1 .

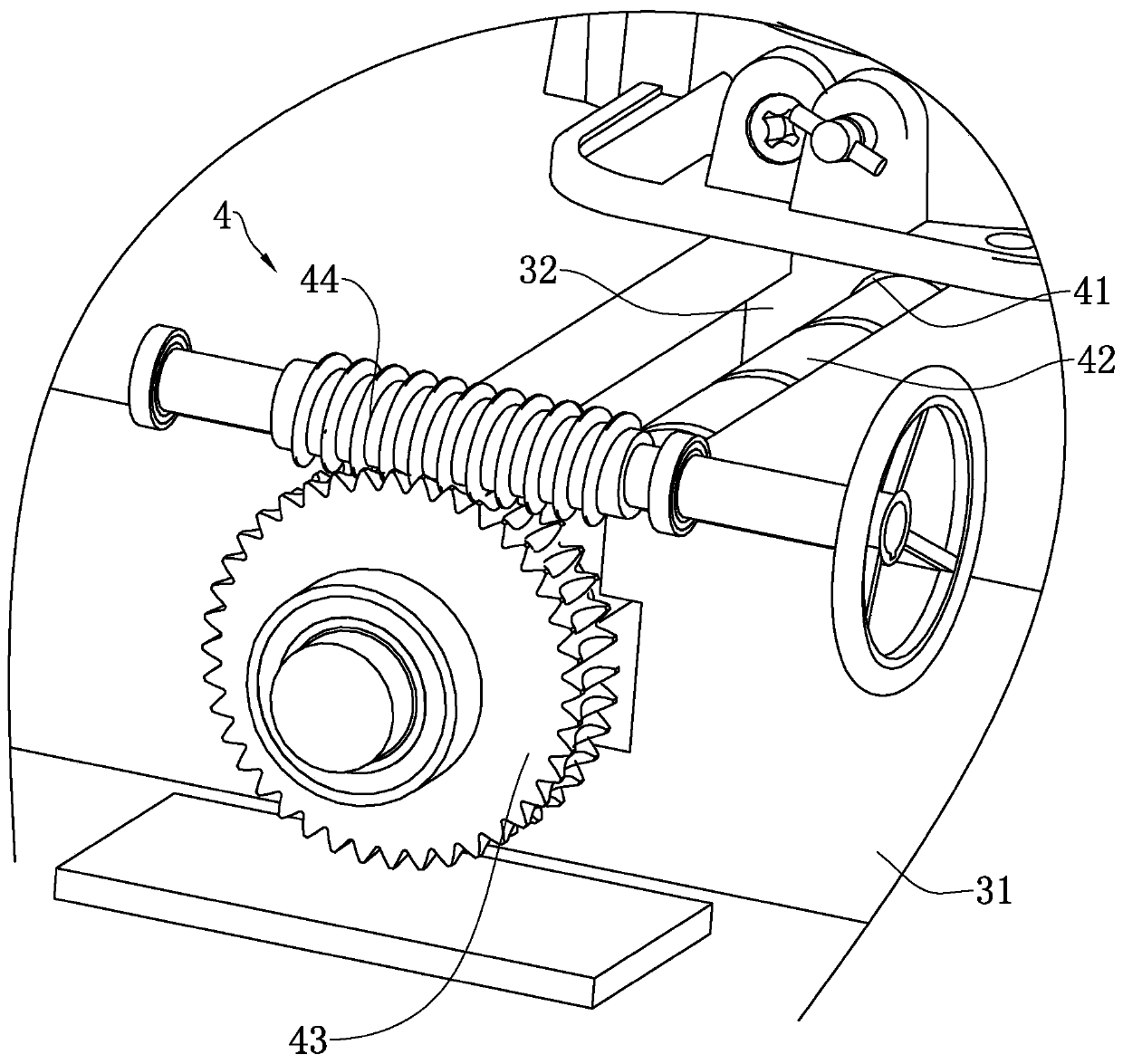

[0049] Positioning blocks 23 are fixed on the two shells 1, and the surface of the positioning blocks 23 facing away from the shell 1 is a plane parallel to the axis of the shell 1. The positioning blocks 23 are detachably connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com