Pen point brush aligning machine capable of removing bad brushes

A technology of nibs and pens, which is applied to other ink pens, ink pen repairs, printing, etc., can solve the problems of time-consuming and cost-intensive work, high work intensity, etc., to reduce time and cost, speed up work efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

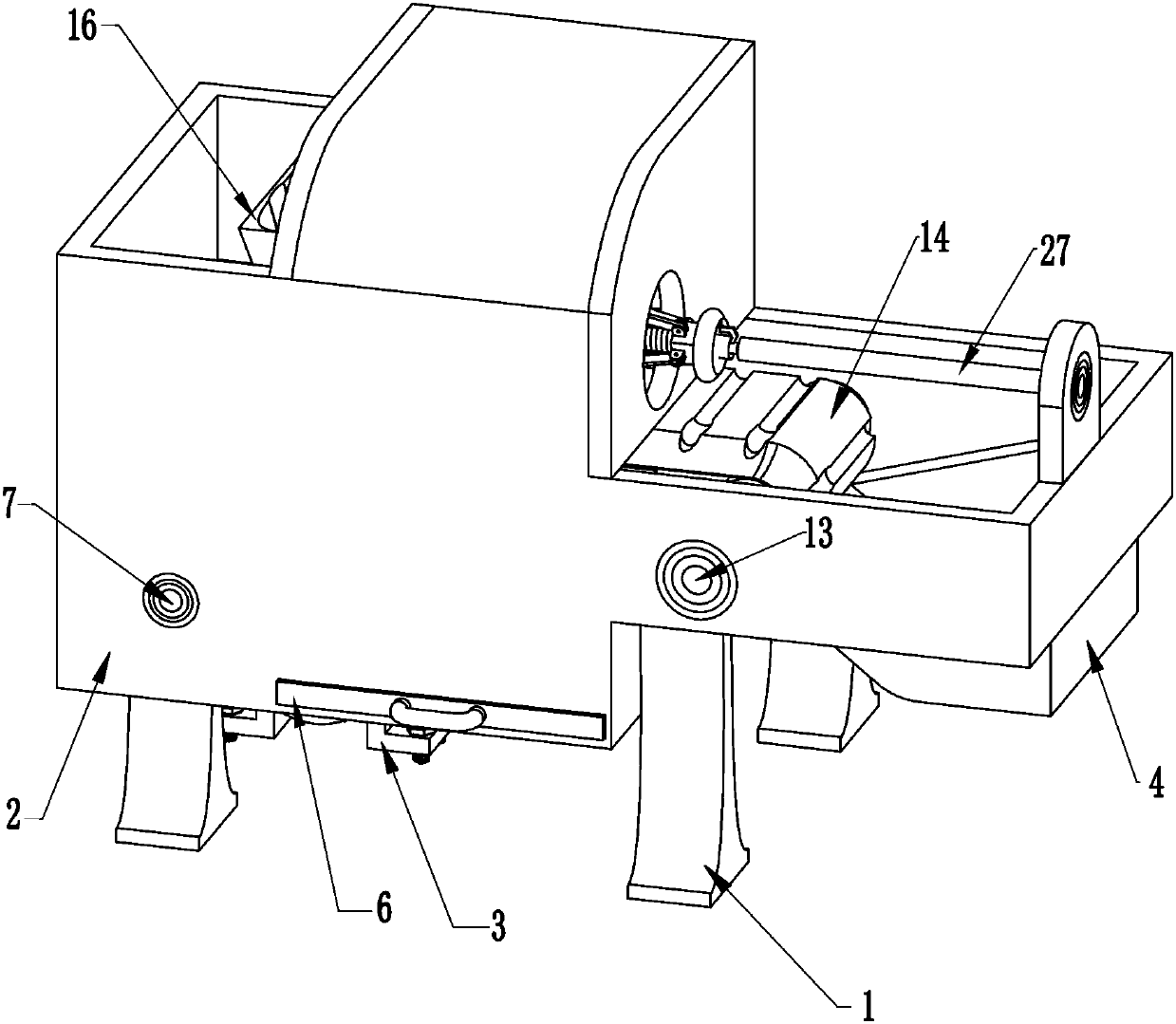

[0025] refer to figure 1 , figure 2 and image 3 , a nib trimming machine capable of removing inferior pens, including a support frame 1, a frame 2, a motor 3, a receiving box 4, a box body 5, a pallet 6, a transmission assembly, a first belt 9, and a telescopic rod 17 , briquetting block 18, first elastic member 19, rubber pressing plate 20, baffle plate 21 and carding assembly, support frame 1 is connected with frame 2, frame 2 bottom is provided with motor 3, and the right side in frame 2 is fixedly provided with The receiving box 4 is fixed with a box body 5 on the inner front side of the frame 2, and the bottom of the box body 5 is slidingly provided with a supporting plate 6, and the frame 2 is provided with a transmission assembly, which is used to transmit writing brushes, and the output shaft of the motor 3 A first belt 9 is wound on it, and two telescopic rods 17 are fixedly connected to the inner top of the frame 2, and the bottom end of the telescopic rod 17 is ...

Embodiment 2

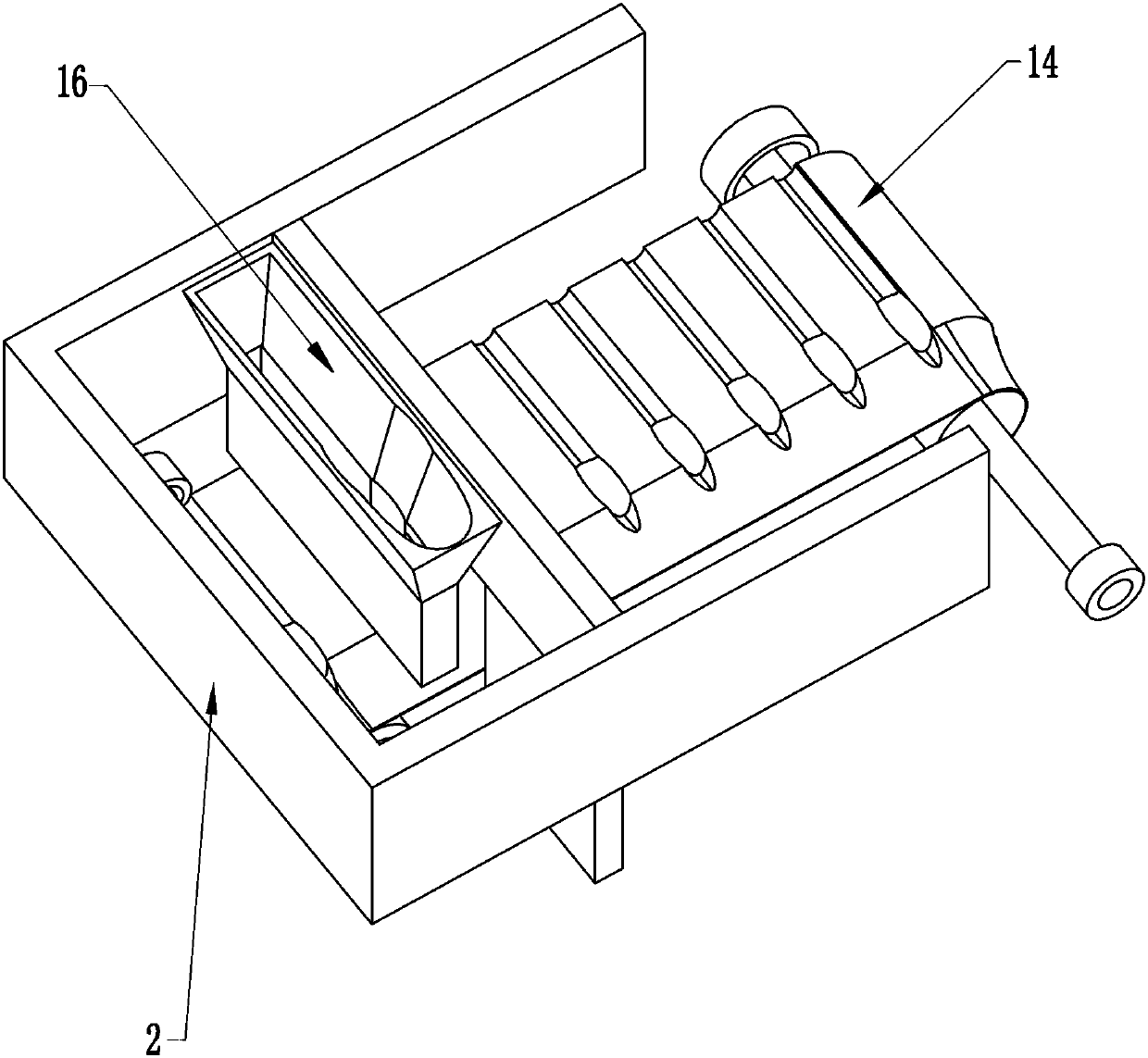

[0032] On the basis of embodiment 1, refer to figure 1 with Figure 6 , also includes a lower hopper 16, the left side of the frame 2 is fixedly provided with a lower hopper 16, and the lower hopper 16 is located above the conveyor belt 14.

[0033] People can put writing brush in the lower hopper 16, and the lower hopper 16 can cooperate with the writing brush groove on the conveyer belt 14, whenever passing through a groove, a writing brush will fall in the writing brush groove by the lower hopper 16, and the lower hopper 16 The feeding opening can only drop a writing brush at a time, and the rest of the writing brushes will not fall out of the lower hopper 16, so that people can not put the writing brushes all the time, and the function of automatically lowering the writing brushes can be realized.

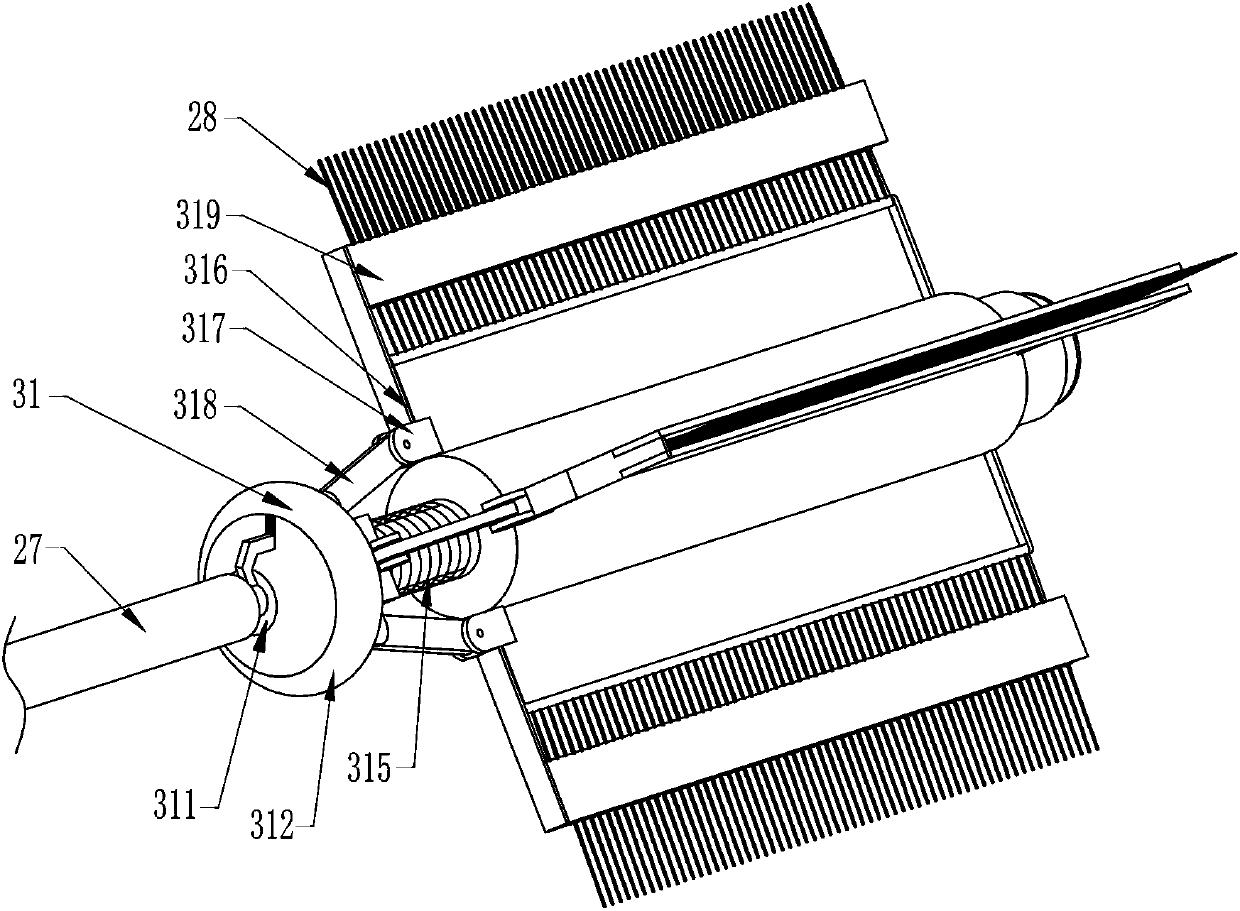

[0034] refer to Figure 4 with Figure 5 , also includes a cleaning device 31, the cleaning device 31 has a first slide block 312, a clamping block 313, a second elastic mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com