Non-bearing frame longitudinal beam

A non-load-bearing, longitudinal beam technology, applied in the direction of vehicle components, substructure, transportation and packaging, can solve the problems of increasing the mass and manufacturing cost of the vehicle, not considering the performance of the longitudinal beam, affecting the bending resistance, etc. Effects of light weight, enhanced bending stiffness, reduced manufacturing and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solution of the present invention.

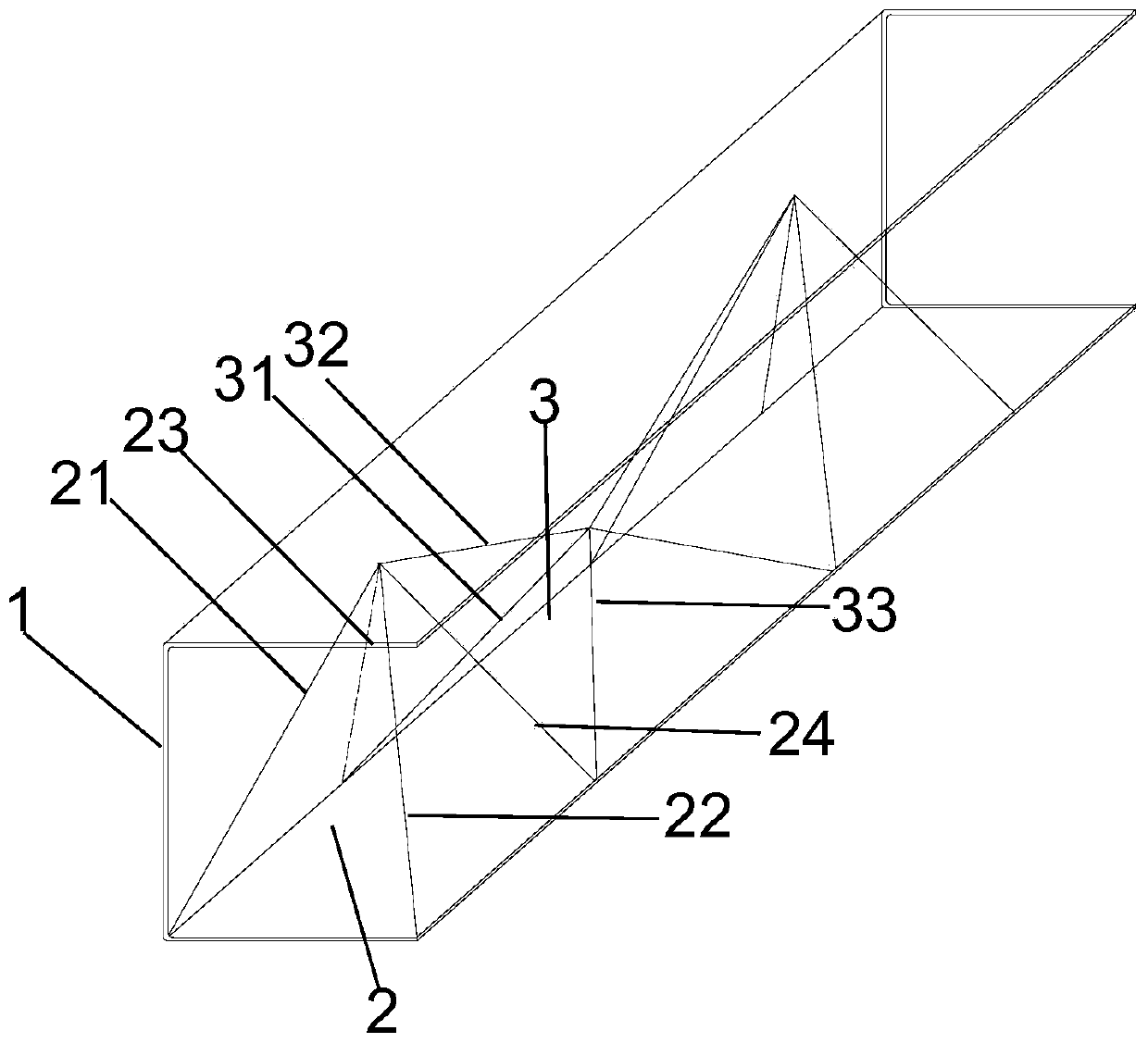

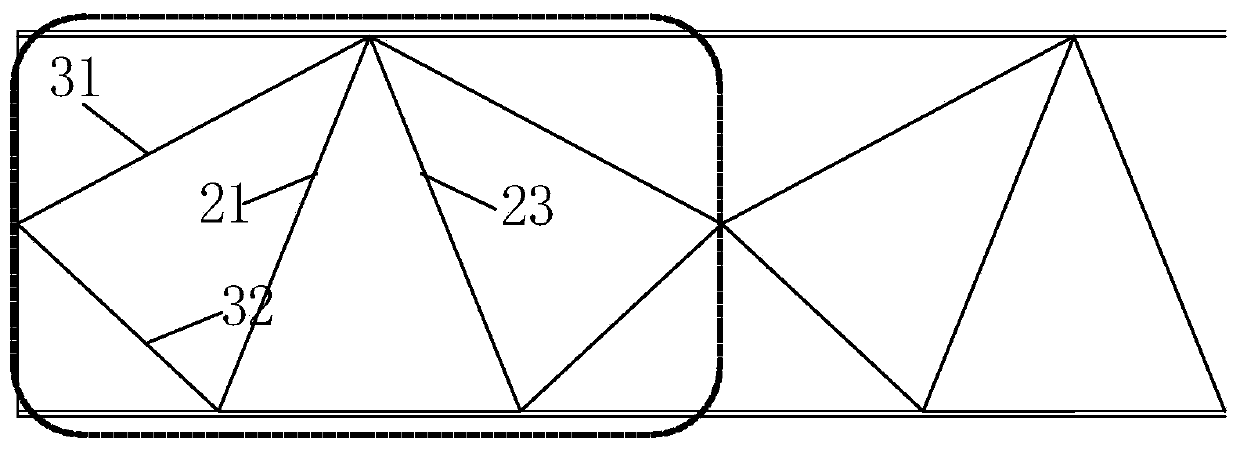

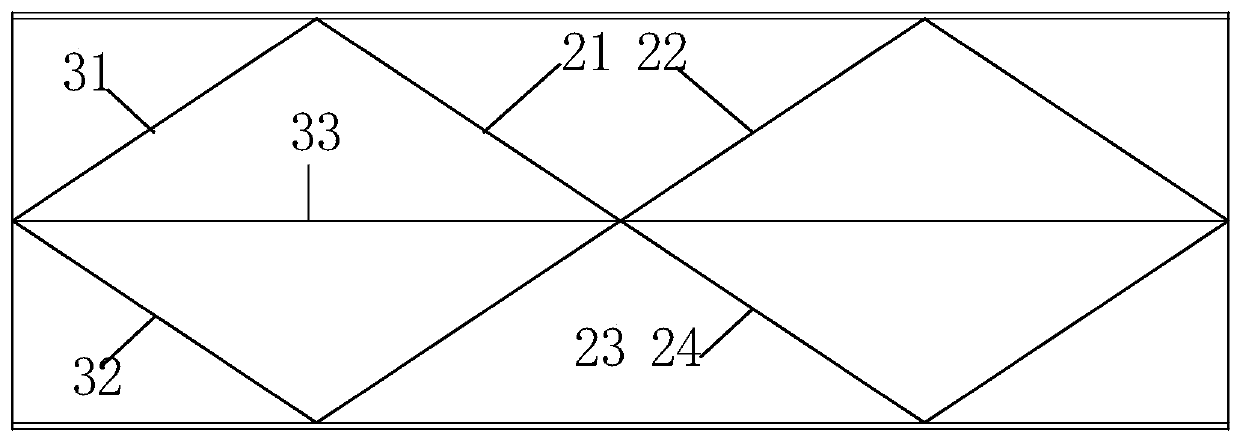

[0018] Such as figure 1 , 2 , 3, and 4, the non-load-bearing frame longitudinal beam of the present invention includes the 匚-shaped side member body 1, and also includes the 匚-shaped side member body 1 inside and along the axis of the 匚-shaped side member body 1, etc. At least two regular quadrangular pyramid frames 2 are arranged at intervals, two fixedly connected tetrahedral frames 3 are provided between two adjacent regular quadrangular pyramid frames 2, and the two ends of the two connected tetrahedral frames 3 are connected to the two The regular quadrangular pyramid frame 2 is fixedly connected.

[0019] Preferably, the regular quadrangular pyramid frame 2 and the tetrahedral frame 3 are integrally cast with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com