Can body sealing cover

A technology for sealing lids and tanks, which is applied in the field of ceramic production, can solve the problems of poor sealing effect of wine storage tanks and affect the quality of wine in tanks, and achieve the effect of improving sealing effect and preservation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

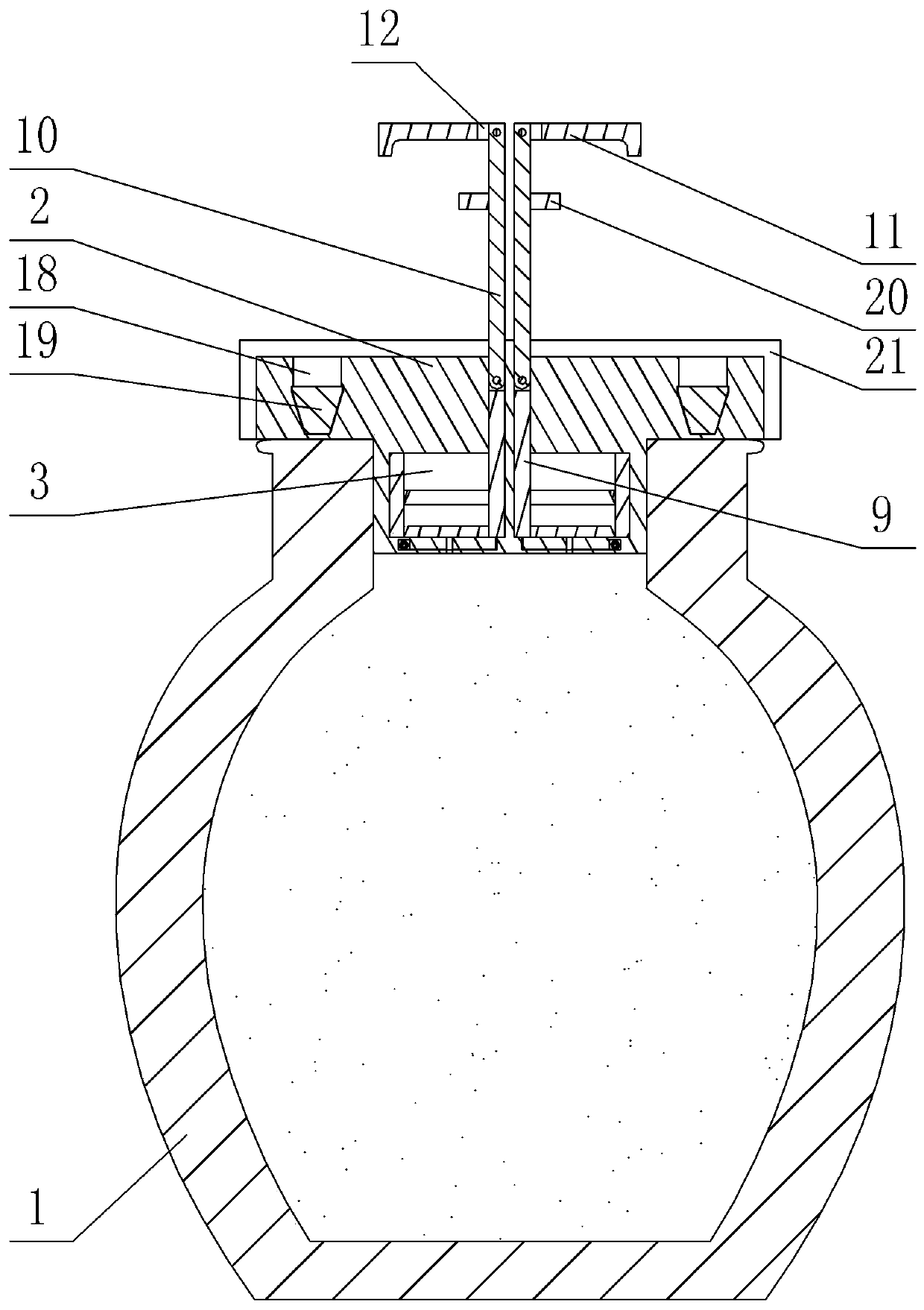

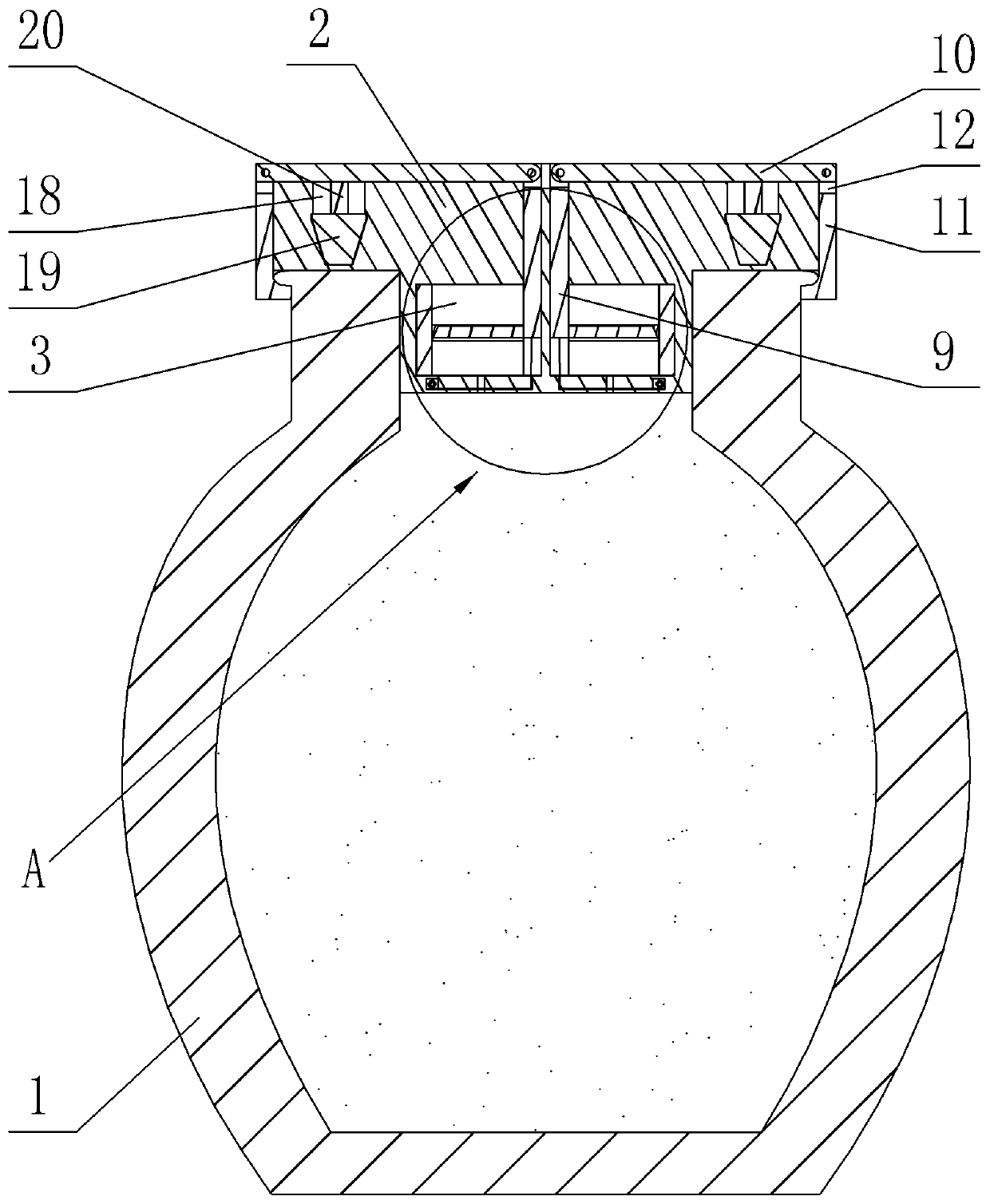

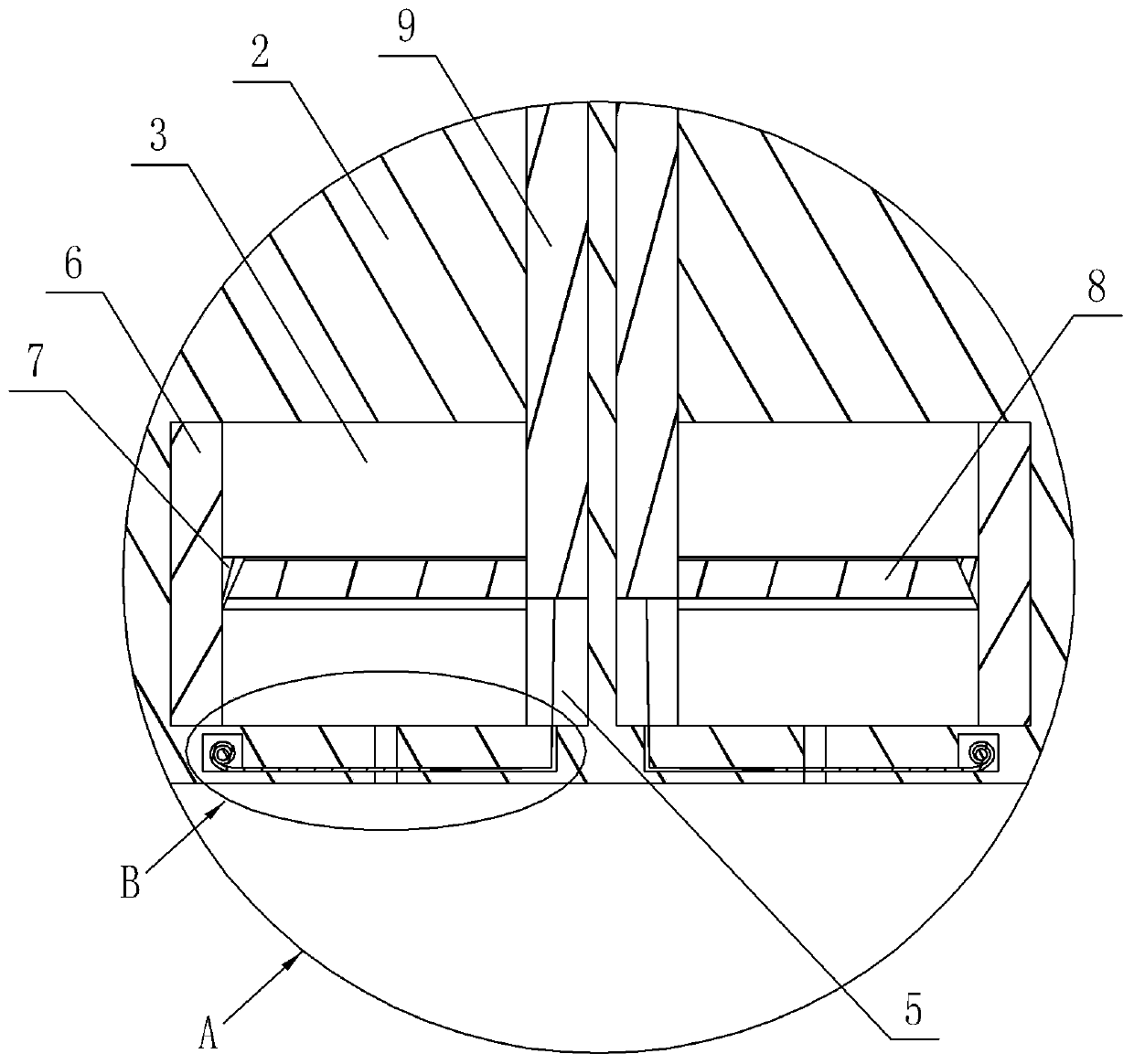

[0022] Embodiment 1 is basically as attached Figure 1-4 Shown: as figure 1 , 2 The tank sealing cover shown is used to seal the filling mouth of the tank body 1, and the filling mouth of the tank body 1 is flanged, and the sealing cover of the tank body 1 includes a cover body 2, a sealing mechanism and a blocking mechanism; image 3 As shown, there is a cavity 3 in the cover body 2, such as Figure 4 As shown, the cover body 2 is provided with a hole 4 communicating with the cavity 3 and the tank body 1, and at the same time, the cover body 2 is also provided with a chute 5 capable of communicating with the cavity 3 and the outside world.

[0023] Such as image 3 As shown, the sealing mechanism includes a pressing ring 6 , a wedge ring 7 , a pressing block 8 and two sealing units. The pressing ring 6 is welded to the wall of the cavity 3 , and the wedge ring 7 is welded to the pressing ring 6 .

[0024] Such as figure 1 , 2 As shown, each sealing unit includes a compr...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 As shown, there is a blind hole 18 on the cover body 2, and a conical pressing block 19 is placed upside down in the blind hole 18, and the aperture diameter of the upper end of the blind hole 18 is smaller than the diameter of the upper end of the pressing block 19; the pressing bar 10 is welded There is a pressing block 20 which can be inserted into the blind hole 18 to press the pressing block 19 . In addition, the cover body 2 is provided with an accommodating groove 21, such as figure 2 The shown compression strip 10 and locking strip 11 are located in the receiving groove 21 .

[0029] The specific implementation process is as follows:

[0030] Such as figure 1 As shown, after closing the cover body 2 on the tank body 1 containing wine, press the cover body 2 with one hand, and pull the locking bar 11, the pressing bar 10 and the pressing bar 9 upward with the other hand. move, thereby driving the block 8 to move; a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap