A kind of non-alkali and chlorine-free concrete quick-setting agent based on magnesium carbonate trihydrate

A technology of magnesium carbonate trihydrate and accelerator, applied in the field of building materials, can solve the problems of high mechanical cost, complicated preparation process, high price and other problems of wet spraying machine, and achieve good adaptability, improved durability and less components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

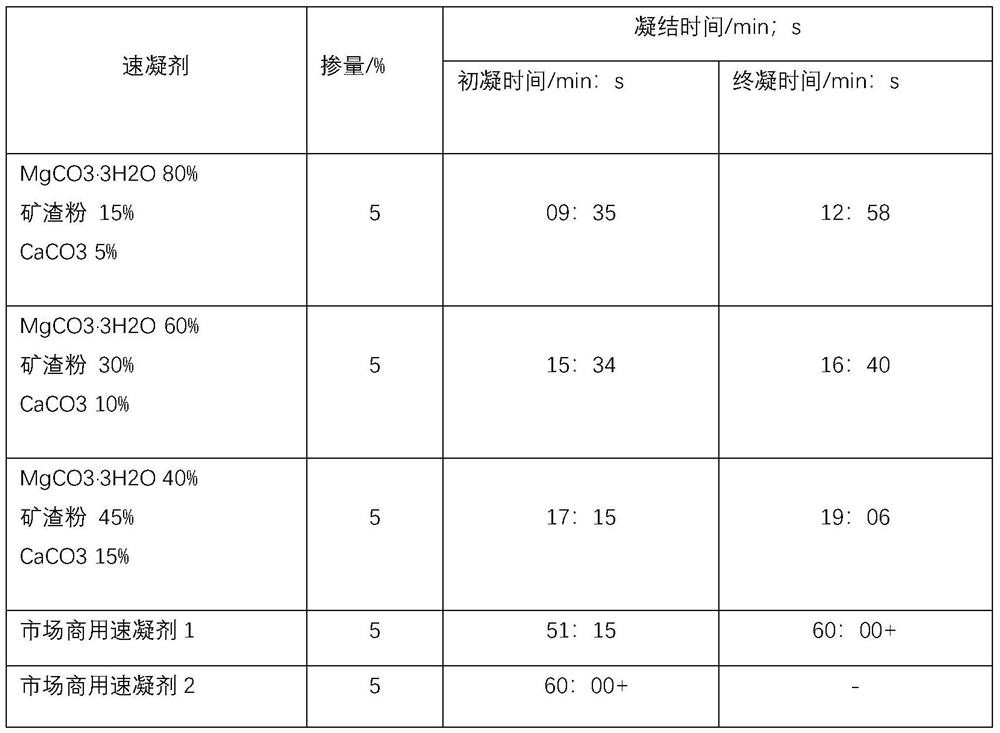

[0034] Embodiment 1: the determination of this accelerator composition ratio

[0035] Referring to GB / T 35159-2017 "Accelerators for Shotcrete", in the experiment, the room temperature was 20.3°C, the water temperature was adjusted to 20±1°C, and the temperature of cement and accelerator components was 19±1°C. Since this accelerator is mainly based on MgCO 3 ·3H 2 O is the main component, so an accelerator with a dosage of 5% is used, and MgCO in the accelerator 3 ·3H 2 O accounts for 80%, 60%, and 40% respectively; slag powder accounts for 15%, 30%, and 45%; calcium carbonate accounts for 5%, 10%, and 15%. The specific experimental results are shown in Table 1.

[0036] According to the results of attached table 1, it can be seen that when the content of accelerator is kept at 5%, the MgCO in the components 3 ·3H 2 The higher the O content, the more obvious the quick-setting effect, so the quick-setting agent should be MgCO 3 ·3H 2 O is the main component, and other a...

Embodiment 2

[0037] Embodiment 2: the determination of this quick-setting agent dosage

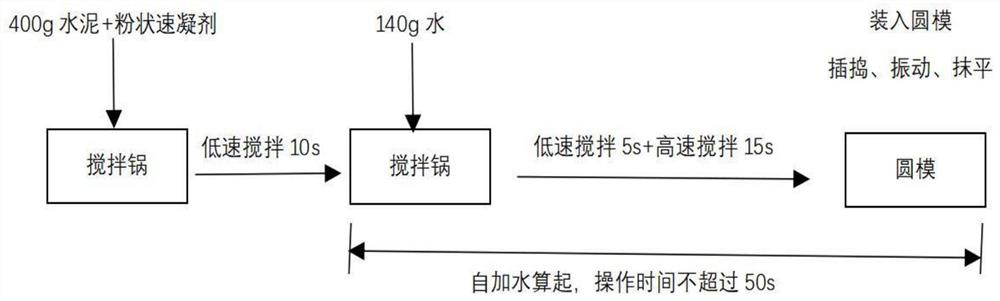

[0038] Referring to GB / T 35159-2017 "Accelerators for Shotcrete", in the experiment, the room temperature was 20.3°C, the water temperature was adjusted to 20±1°C, and the temperature of cement and accelerator components was 19±1°C. Because this quick-setting agent in embodiment 1 MgCO 3 ·3H 2 The effect is best when O accounts for 80%, so the composition is 80% MgCO 3 ·3H 2 O, 15% slag powder, 5% calcium carbonate accelerator, the amount of accelerator was 3%, 5% and 7% respectively for initial and final setting experiments. Specific experimental methods such as figure 1 , see the attached table 2 for the specific experimental results.

[0039] It can be seen from the results of attached table 2 that the quick-setting agent component is kept at 80% MgCO 3 ·3H 2 O, 15% slag powder, 5% calcium carbonate, the more the accelerator is added, the more obvious the quick-setting effect will be.

Embodiment 3

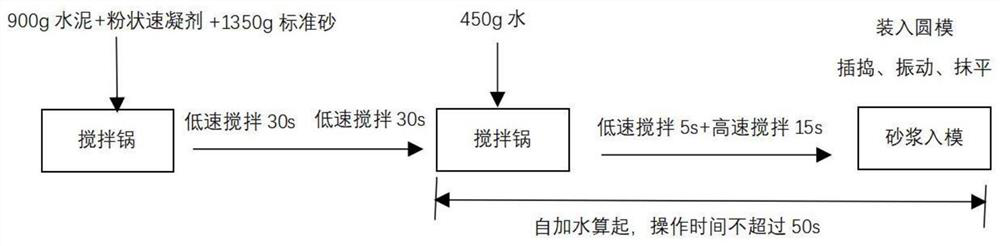

[0040] Embodiment 3: Determination of the compressive strength of this quick-setting agent cement mortar

[0041] Referring to the relevant national specifications for the compressive strength test of accelerators, in the experiment, the room temperature was 20.3°C, the water temperature was adjusted to 20±1°C, and the temperature of cement, sand and accelerator components was 19±1°C. According to the dosage experiment of accelerator, this experiment adopts the dosage of accelerator 0%, 3%, 7% to conduct 1d and 28d compressive strength experiments of cement mortar. Specific experimental methods such as figure 2 , see the attached table 2 for the specific experimental results.

[0042] It can be seen from the results of attached table 2 that the quick-setting agent component is kept at 80% MgCO 3 ·3H 2 When O, 15% slag powder, 5% calcium carbonate, cement mortar 1d appears early strength phenomenon, compared with blank group, the compressive strength of 3% quick-setting age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com