A tower spring with high life and high hardness and its production and processing technology

A processing technology and high hardness technology, applied in the direction of leaf springs, springs, springs/shock absorbers, etc., can solve problems such as uneven force, damage to high-speed infusion pumps, and difficult installation of parts, so as to achieve small deformation under force, Increased service life, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

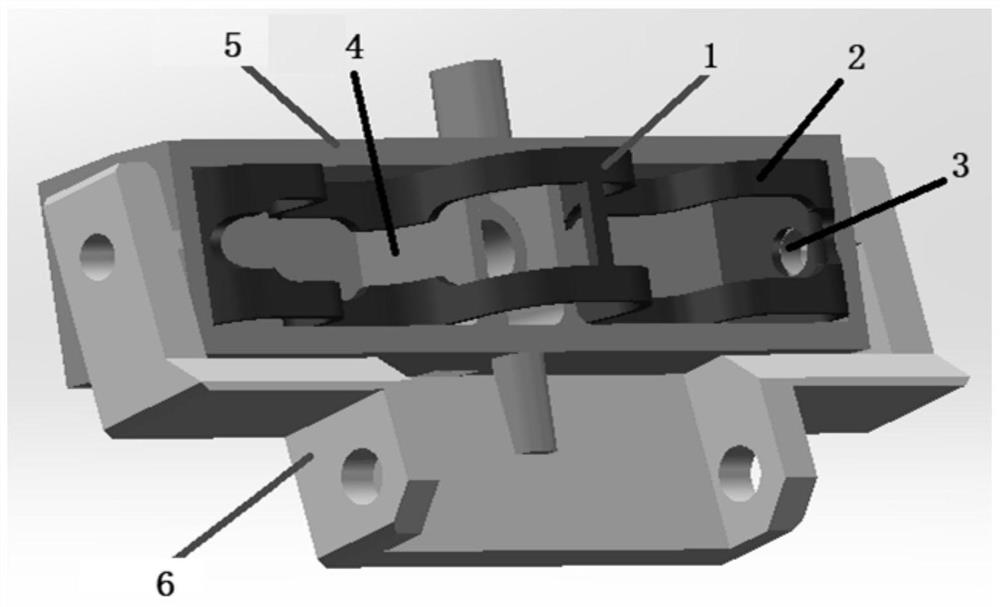

[0031] Embodiment 1: 1. Rib top; 2. Shoulder; 3. Fixing hole; 4. Groove; 5. Cover plate; 6. Shift fork.

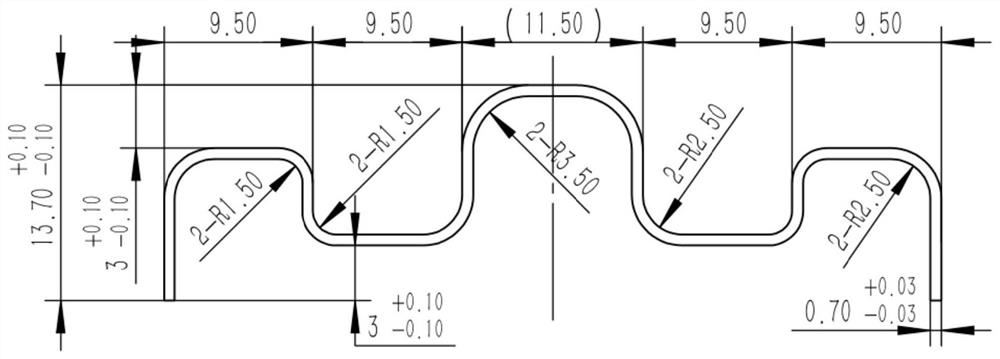

[0032] Such as Figure 2 to Figure 3d In the example shown, the individual dimensions of the tower springs are based on Figure 3a-Figure 3d After processing and production, after molding, heat treatment, and anti-rust process steps, it is applied to the cover plate 5 inside the pressure tube device of the high-speed infusion pump. The tower spring is installed inside the cover plate 5 and can be fixed on it with M2.5*10 screws. On the shift fork 6, the screw size is set according to the diameter of the fixing hole 3, and the rib top 1 in the middle of the tower spring is on the metal door cover plate (the metal door cover plate is installed on the front of the door body, and the door film is pasted on it), wherein the rib The shock-absorbing pit sunken in the middle of the top 1 and the two shoulders 2 does not contact with anything, and mainly provides elastic force for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com