Water conveying pipeline with oxidation resistance

A water pipeline and anti-oxidation technology, used in pipeline protection, pipeline anti-corrosion/rust protection, pipeline damage/wear prevention, etc., can solve the problems of inconvenient construction, poor anti-oxidation effect, etc. The effect of enhancing the antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

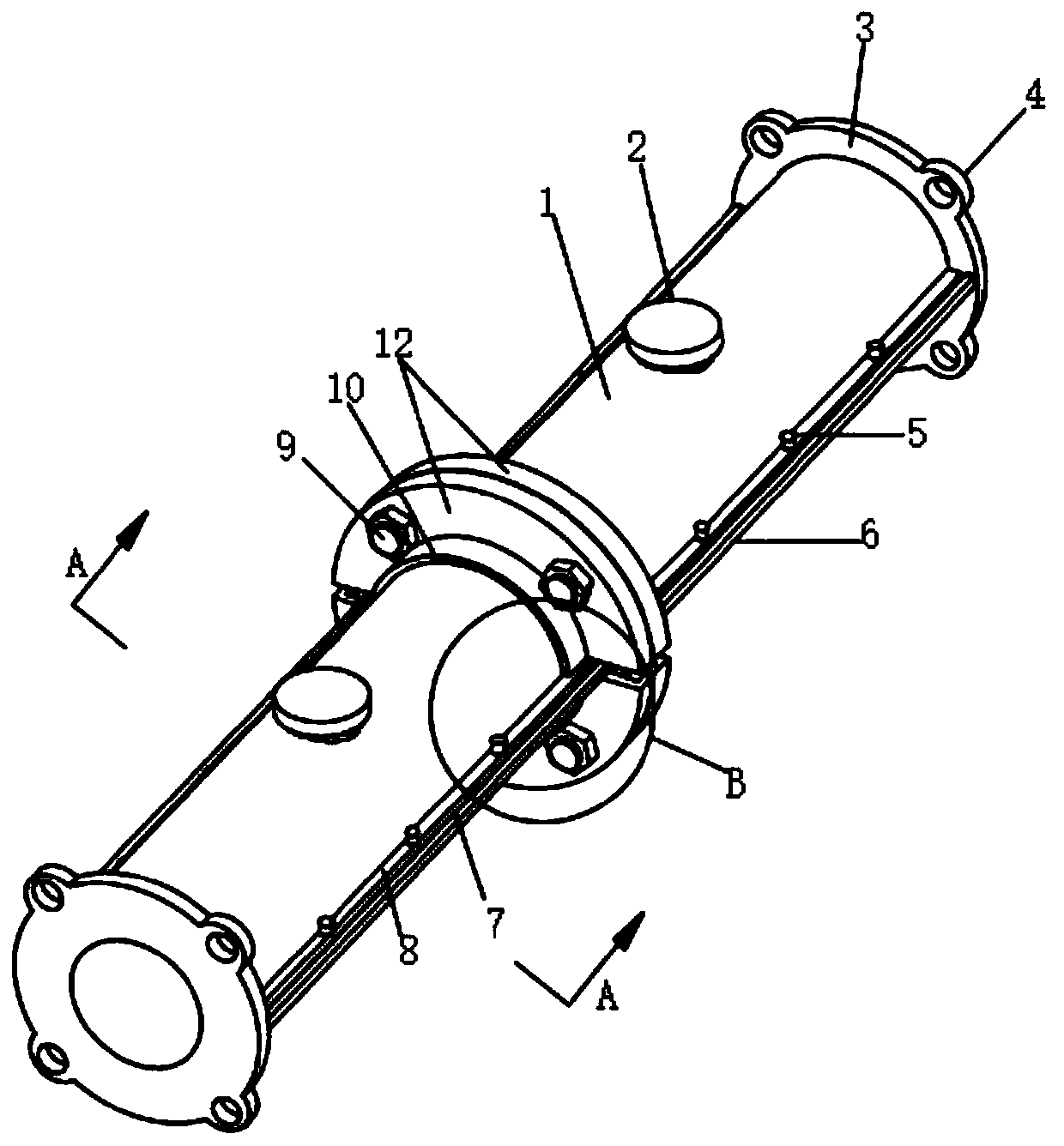

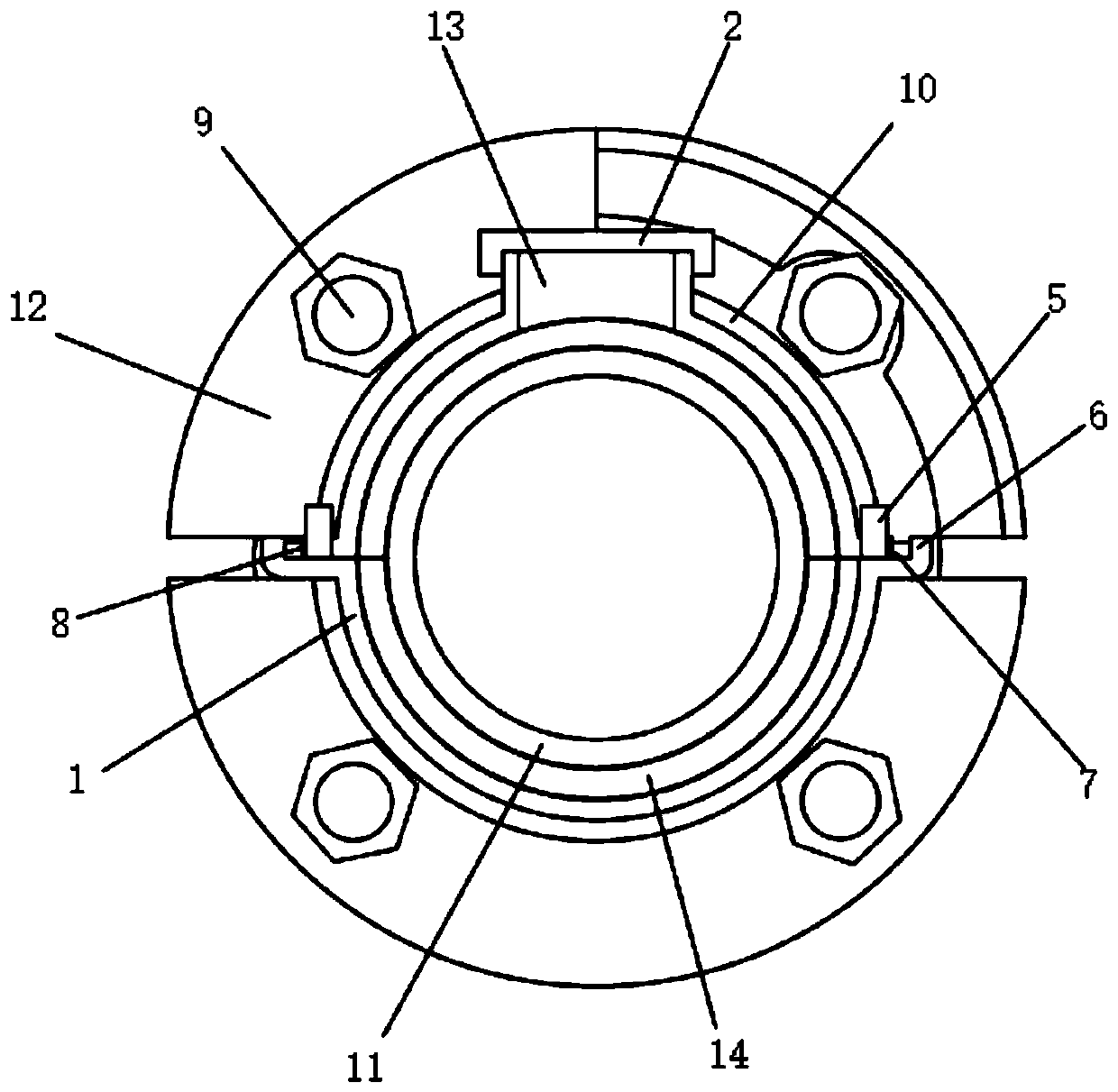

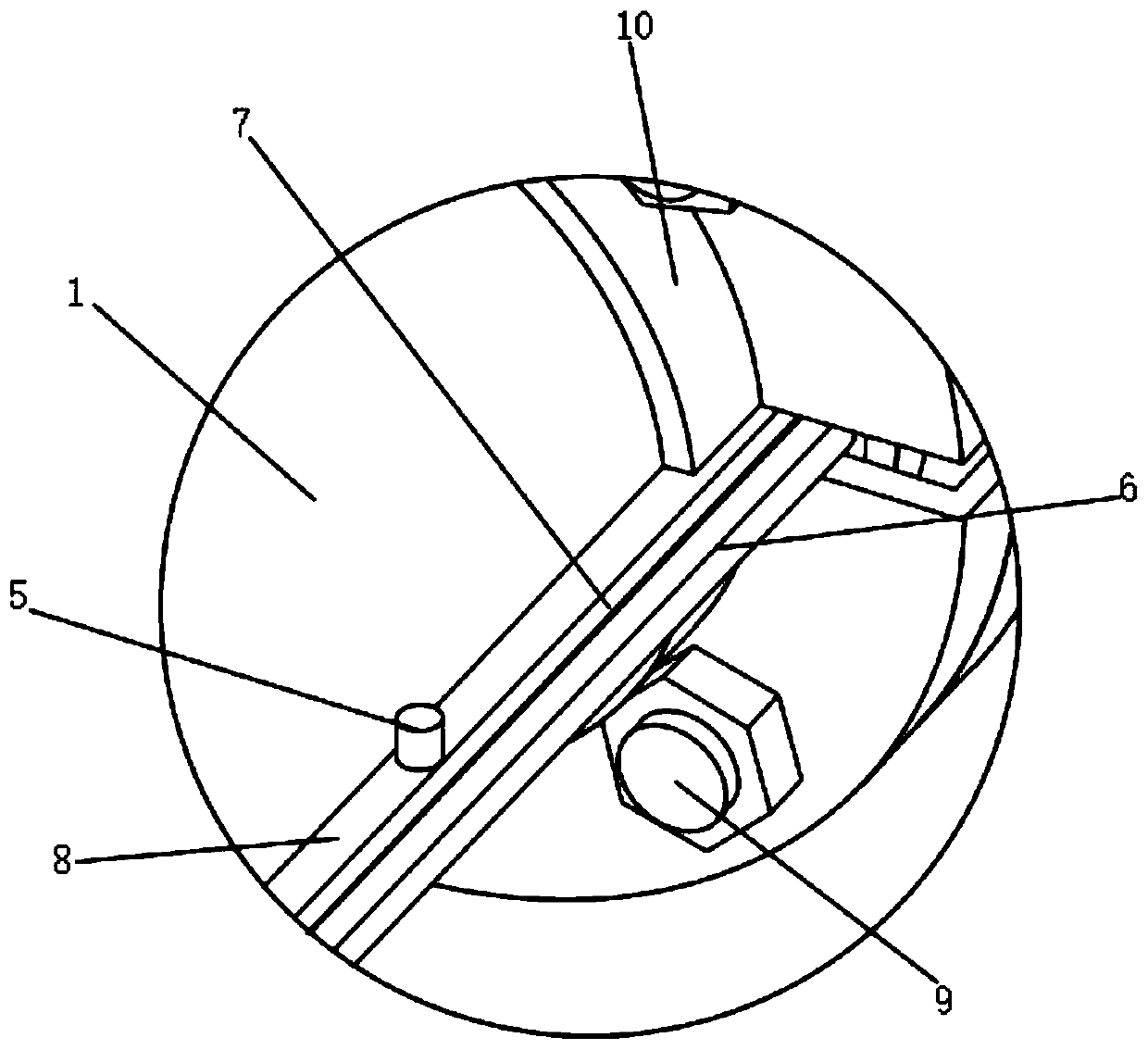

[0033] As mentioned above, an anti-oxidation water pipeline and its preparation process include a pipeline main body 11, two semi-cylindrical protective shells 1 are wrapped on both sides of the pipeline main body 11, and the inner wall of the protective shell 1 is provided with oil-immersed Cotton 14, oil-soaked cotton 14 is impregnated with anti-rust oil, both sides of the two protective shells 1 are connected by a sealed connection structure, and the surface of the pipeline main body 11 is provided with an anti-oxidation layer. The protective shell 1 is made of plastic, and the pipeline main body 11 is a cast iron pipe. The sealing connection structure includes a sealing groove 6 arranged on both sides of one of the protective shells 1, and a sealing plate 8 is connected to both sides of the other protective shell 1, and the sealing plate 8 is inserted into the sealing groove 6, and the end of the sealing plate 8 There is a gap with the inner wall of the sealing groove 6, a...

Embodiment 2

[0047] As mentioned above, an anti-oxidation water pipeline includes a pipeline main body 11, two semi-cylindrical protective shells 1 are wrapped on both sides of the pipeline main body 11, and the inner wall of the protective shell 1 is provided with oil-soaked cotton 14, The oil-soaked cotton 14 is impregnated with anti-rust oil, both sides of the two protective shells 1 are connected by a sealed connection structure, and the surface of the pipeline main body 11 is provided with an anti-oxidation layer. The two semi-cylindrical protective shells 1 can facilitate the installation of the pipeline at the construction site, and quickly cover and protect the main body of the pipeline; the oil-soaked cotton 14 in the protective shell 1 can conveniently form an oil layer on the outer wall of the pipeline main body 11 For protection, the air on the surface of the pipeline main body 11 is discharged to improve the oxidation resistance; the surface of the pipeline main body 11 is prov...

Embodiment 3

[0049] As mentioned above, an anti-oxidation water pipeline includes a pipeline main body 11, two semi-cylindrical protective shells 1 are wrapped on both sides of the pipeline main body 11, and the inner wall of the protective shell 1 is provided with oil-soaked cotton 14, The oil-soaked cotton 14 is impregnated with anti-rust oil, both sides of the two protective shells 1 are connected by a sealed connection structure, and the surface of the pipeline main body 11 is provided with an anti-oxidation layer.

[0050]Both ends of the pipe main body 11 are connected with a disc-shaped connecting piece 3 coaxial therewith, and the connecting piece 3 has connecting holes 4 in a circular array around its edge, and the ends of the adjacent pipe main bodies 11 are coaxially butted. Connecting bolts 9 are commonly connected to the connecting holes 4 on the connecting piece 3 . A semi-cylindrical sliding sleeve 10 is slidably connected to the outer wall of the protective case 1, and a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com