Automatic debugging device for air conditioner

An automatic debugging and automatic adjustment technology, applied in the field of air conditioning, can solve problems such as errors, time wasting, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

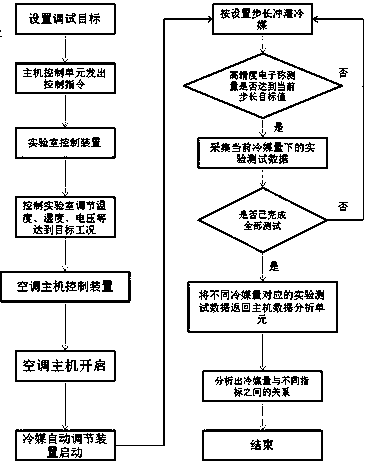

[0017] The automatic refrigerant adjustment of the present invention comprises the following steps:

[0018] Taking the automatic adjustment experiment of a fixed-frequency 1.5P air conditioner refrigerant as an example, the automatic adjustment of refrigerant includes the following steps:

[0019] (1) Set the initial amount of refrigerant for debugging as 0.8kg, the target amount as 1.2kg and the adjustment step as 0.05kg;

[0020] (2) The host control unit issues control commands;

[0021] (3) The laboratory control device controls the experiment to adjust to the nominal refrigeration working condition, that is, the dry bulb temperature outside the laboratory is 35 degrees, the dry bulb temperature of the indoor side air inlet is 27 degrees, and the voltage is 220V. After reaching the working condition of the debugging target, enter the next step;

[0022] (4) The control device of the main unit of the air conditioner controls the opening of the main unit of the air conditi...

Embodiment 2

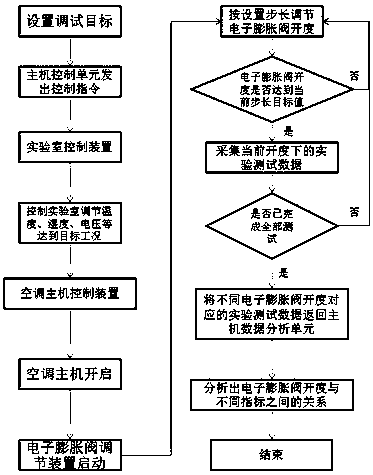

[0030] Taking the automatic adjustment experiment of a fixed-frequency 1.5P air-conditioning refrigerant as an example, the automatic adjustment of the electronic expansion valve of the present invention includes the following steps:

[0031] (1) Set the initial opening of the electronic expansion valve of the debugging target to 20, the target opening to 300 and the adjustment step to 20;

[0032] (2) The host control unit issues control commands;

[0033] (3) The laboratory control device controls the experiment to adjust to the nominal refrigeration working condition, that is, the dry bulb temperature outside the laboratory is 35 degrees, the dry bulb temperature of the indoor side air inlet is 27 degrees, and the voltage is 220V. After reaching the working condition of the debugging target, enter the next step;

[0034] (4) The control device of the air conditioner main engine controls the opening of the air conditioner main engine and the automatic adjustment device of th...

Embodiment 3

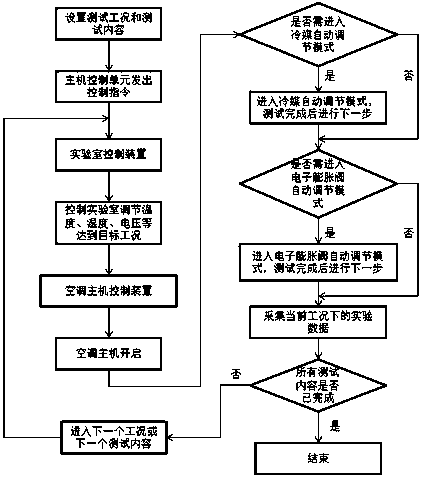

[0043] The present invention can also be used in combination of the two modes of implementation case 1 and implementation case 2, that is, the electronic expansion valve and the linkage adjustment of the refrigerant filling amount, the steps are similar to the implementation case 1 and implementation case 2, the difference is that the linkage adjustment mode can test different refrigerants The data under the two variables of filling volume and different electronic expansion valve steps are used to evaluate the optimal refrigerant filling volume and electronic expansion valve steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com