High-reliability electric bolt releasing structure and method based on position detection

A reliable and electric technology, used in weapon accessories, offensive equipment, training matching components, etc., can solve problems such as overshoot, high-speed impact, stall, frequent failure, damage to structural parts, etc., to achieve simple closed-loop control and avoid overshoot. Punch, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

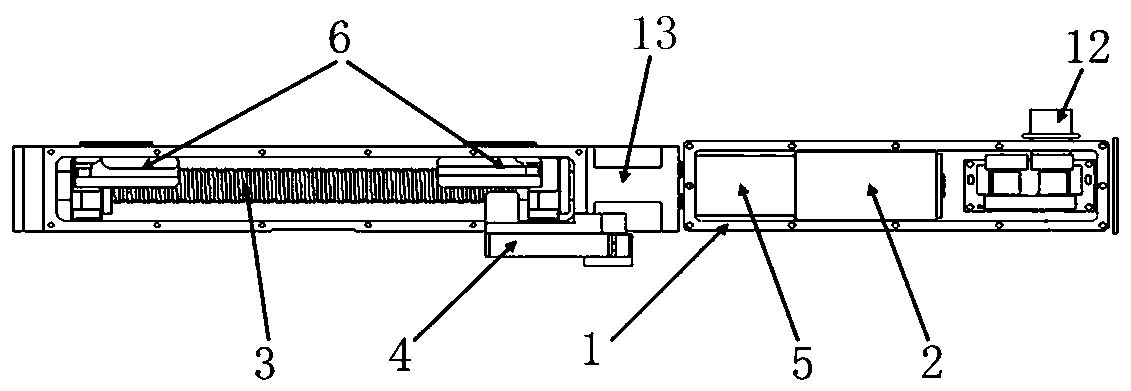

[0017] A high-reliability electric bolt-opening structure based on position detection of the present invention includes a bolt-opening structure housing 1 and a motor 2 arranged in the bolt-opening structure housing 1. The motor 2 is connected to a ball screw 3 through a reducer 5, and the ball screw A bolt-opening slider 4 is threaded on the bar 3, limit sensors 6 are arranged at both ends of the ball screw 3, and a position detection device 13 for real-time detection of the moving position of the bolt-opening slider 4 is connected to the reducer 5. The position detection device 13 is fixedly arranged in the shell 1 of the opening structure.

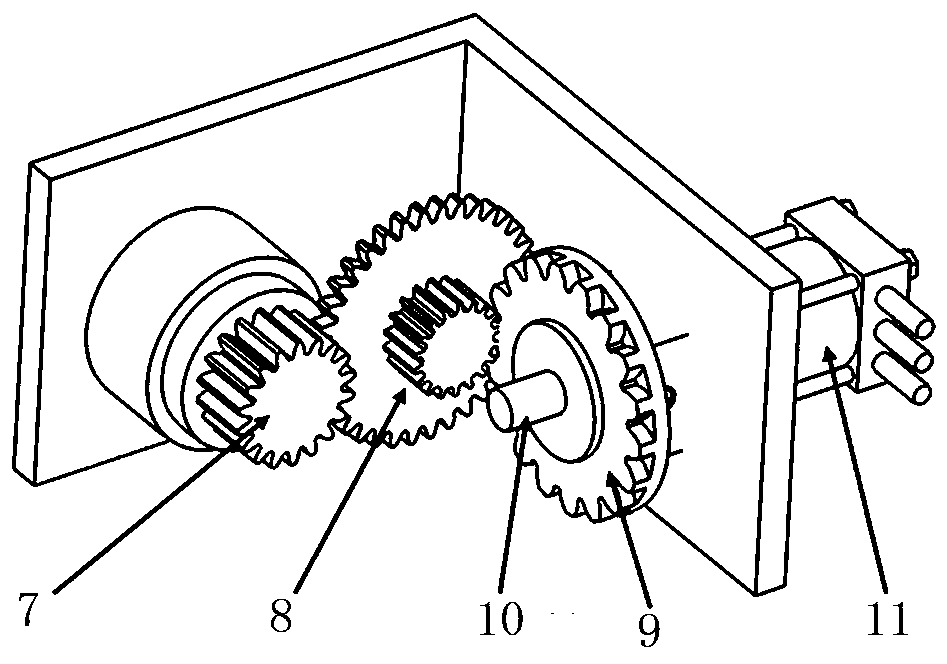

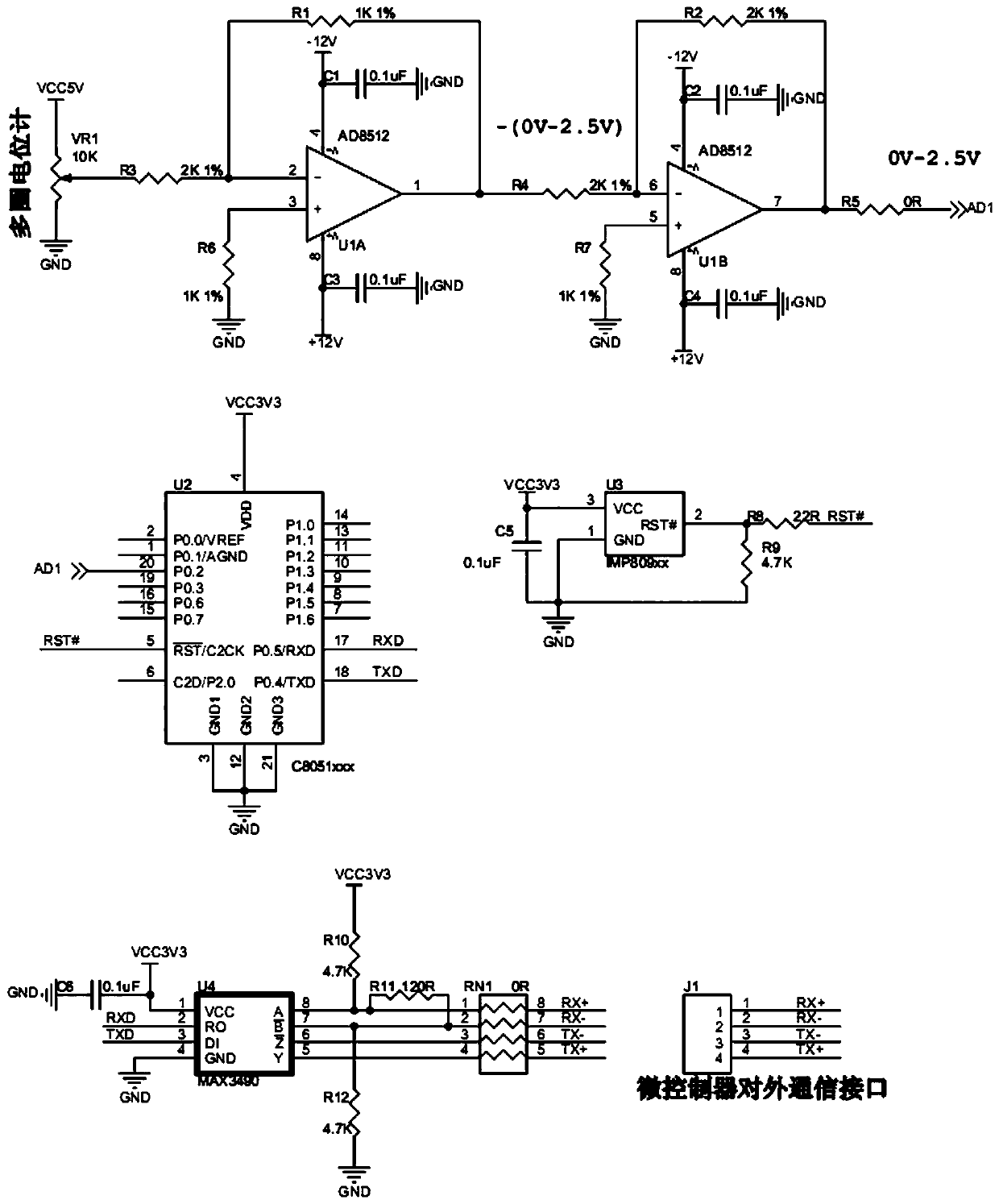

[0018] The position detection device 13 includes a multi-turn potentiometer 11, and a potentiometer shaft 10 is connected to the potentiometer 11 in rotation, and the potentiometer shaft 10 is connected to the speed reducer 5 through a connection device. When the speed reducer 5 passes through the connection device The potentiometer sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com