Step-by-step air return and exhaust lift valve debugging test bed and inflation test and pressure adjustment method

A test bench and pressure technology, which is applied in the direction of mechanical valve testing, fluid pressure control, electric fluid pressure control, etc., can solve the problems of difficult data acquisition of gas lift valves, and achieve the effect of quick action and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

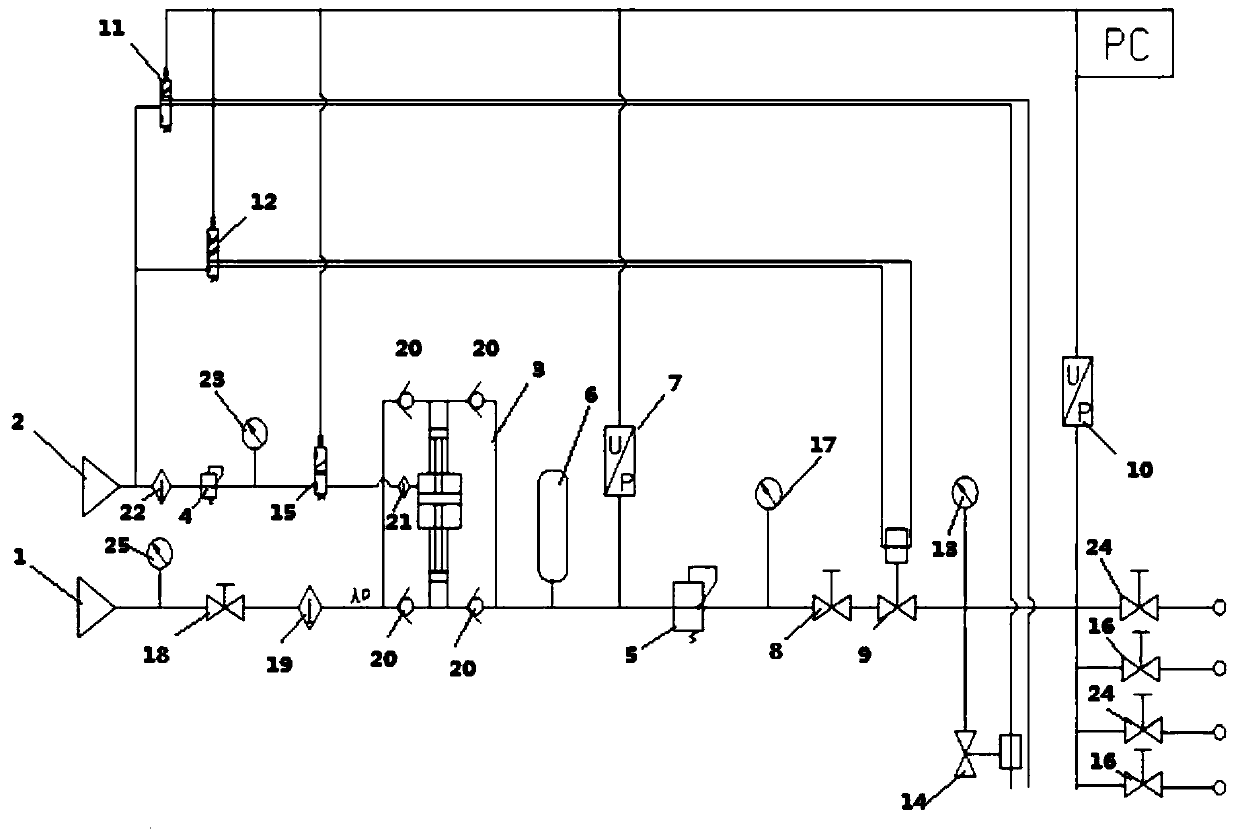

Method used

Image

Examples

Embodiment 1

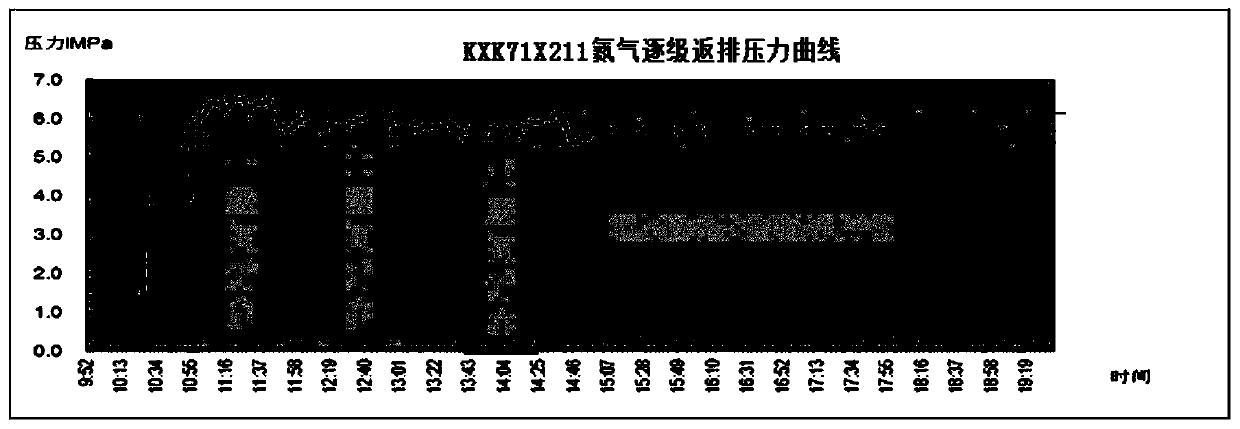

[0073] Ken 71X211 is a newly commissioned well in the old area of Xiaguantao Formation of Kenxi Oilfield. The oil reservoir is buried at a depth of 1630 meters. Due to years of exploitation in the formation, the pressure drop has been relatively large, from the original 14.9Mpa to the current 8.6MPa. Due to low formation pressure, mud invaded during the drilling process, causing serious formation pollution. In order to remove the mud blockage and improve the plugging removal effect, the gas lift flowback blockage removal process is adopted

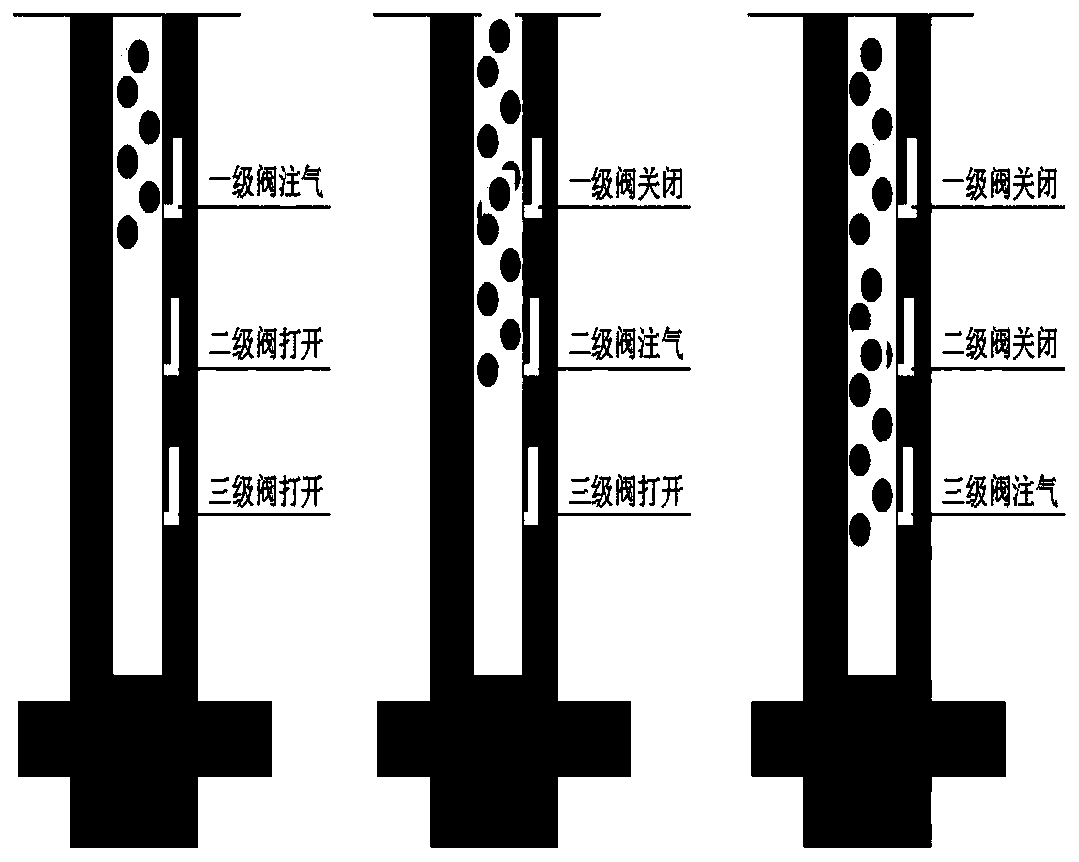

[0074] Such as figure 2 The structure shown: Gas lift valves are installed at different depths of the pipe string according to the cloth valve design. The working principle is to inject nitrogen gas from the oil casing annulus, open the switch through the gas lift valve, enter the oil pipe, and lift the fluid in the pipe to the surface step by step, so that the bottom hole pressure gradually decreases, the flowback pressure difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com