Formaldehyde sensor based on zinc oxide/zinc cobaltate composite material and its preparation method

A composite material and sensor technology, applied in the direction of material resistance, material analysis, material analysis through electromagnetic means, etc., can solve problems such as catalytic activity limitation, and achieve the effect of improving gas sensitivity response, small size, and good detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

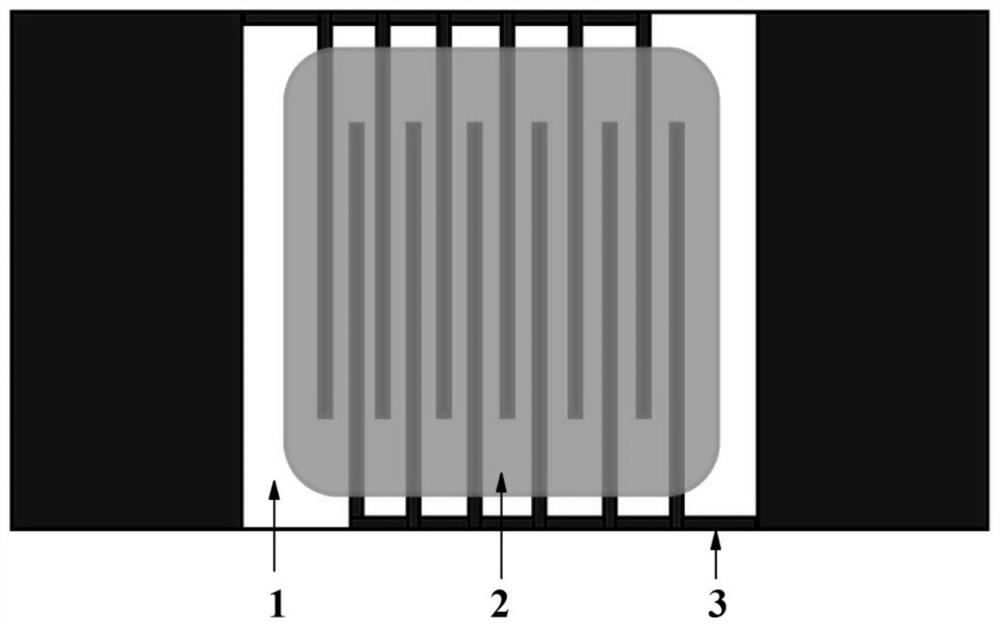

[0041] 1. Treatment of Pd metal finger electrodes:

[0042] First, use acetone and ethanol cotton balls to wipe the Al with Pd metal inter-finger electrodes (prepared by screen printing technology). 2 o 3 substrate, and then Al with Pd metal interfinger electrodes 2 o 3 The substrate was placed in acetone, ethanol and deionized water in turn, ultrasonically cleaned for 10 minutes, and finally dried at 100 °C;

[0043] The present invention uses screen printing technology on Al 2 o 3 Prepare the Pd metal finger electrode on the substrate, the specific method is as follows: mix the ink [Jiahua JX07500487], Pd powder, and diluent in a mass ratio of 1:1:2, stir to make a paste; then pour the paste into On the screen plate with the pattern of the inserted finger electrode, scrape the paste at an inclination angle of 30° and a pressure of 5 Newtons, in Al 2 o 3The electrode is printed on the substrate and dried, and the preparation of the Pd metal finger electrode is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com