Method for measuring migration quantity of colorant smoke in filter tip by simulating cigarette smoking

A colorant and migration technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of interference in the determination of trace thermal migration components, large deviation of measurement results, and complex device structure, and achieve good rigidity, good adsorption, chemical stability and other problems. Inert good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

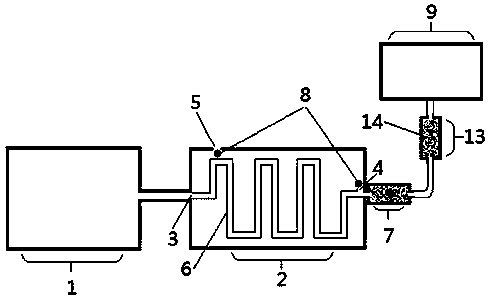

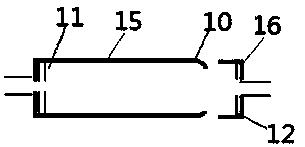

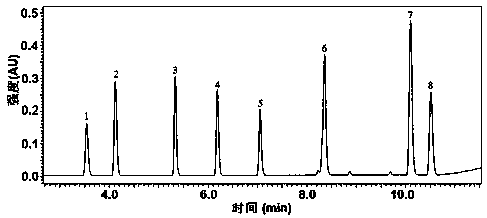

[0101] The tested filters were artificially added coloring agents to the filter tow, and the addition amount of 8 kinds of coloring agents including lemon yellow, amaranth, carmine, sunset yellow, allura red, bright blue, acid red and erythrosine were equal. It was 24.8 μg / g. The smoking parameters of the smoking machine were the ISO standard suction mode (1 puff at intervals of 1 minute, the suction volume of each puff was 35 mL, and the suction duration was 2 seconds), and a total of 9 puffs were taken. The purge airflow adopts a gradual temperature rise mode, and the airflow temperature of each puff is set with reference to the puff-by-puff temperature of the smoke flow through the filter part when the cigarette is actually burned (according to the thermocouple measurement results).

[0102] Put the tested filter tip into the purge pipe, and connect the various parts of the device with a heat-insulating rubber hose. Start the smoking machine for suction, let the hot air fl...

Embodiment 2

[0106] The tested filters were artificially added coloring agents to the filter tow, and the addition amount of 8 kinds of coloring agents including lemon yellow, amaranth, carmine, sunset yellow, allura red, bright blue, acid red and erythrosine were equal. It was 24.8 μg / g. The smoking parameters of the smoking machine were the ISO standard suction mode (1 puff at intervals of 1 minute, the suction volume of each puff was 35 mL, and the suction duration was 2 seconds), and a total of 9 puffs were taken. According to the principle of risk maximization and amplification, the highest temperature in actual cigarette smoking (that is, the temperature of the last puff) is 70°C for purging.

[0107] Put the tested filter tip into the purge pipe, and connect the various parts of the device with a heat-insulating rubber hose. Start the smoking machine for suction, let the hot air flow pass through the purge pipe, and the purged colorant is collected by the trap [the trap cavity is (...

Embodiment 3

[0111] The tested materials are popping beads made of cigarette wall material. The content of colorants in the wall material is: lemon yellow 322.5 μg / g amaranth 205.6 μg / g, bright blue 31.4 μg / g. Fragrance of glyceryl caprate. The smoking parameters of the smoking machine were the ISO standard suction mode (1 puff at intervals of 1 minute, the suction volume of each puff was 35 mL, and the suction duration was 2 seconds), and a total of 9 puffs were taken. The purge airflow adopts a gradual temperature rise mode, and the airflow temperature of each puff is set with reference to the puff-by-puff temperature of the smoke flow through the filter part when the cigarette is actually burned (according to the thermocouple measurement results).

[0112] Take 10 particles (0.22 ~ 0.3g) of the popping beads for the test, wrap them with cellulose acetate and crush them, quickly put them into the purge pipe, and connect the various parts of the device with heat-insulating rubber hoses. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com