Pulse current auxiliary type pre-welding preheating and post-welding stress relief method for high-strength titanium alloy

A technology of pulse current and pre-welding preheating, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problem of inconsistency between the surface and core of thick plates, high requirements for heating furnace specifications and temperature control, and heat radiation. Solve problems such as slow heating and temperature rise, achieve good technical application and market prospects, improve welding quality, and uniform temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

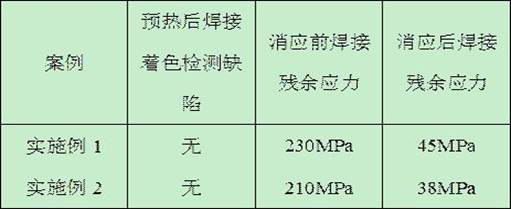

Embodiment 1

[0044] A pulse current-assisted method for pre-welding preheating and post-welding elimination of high-strength titanium alloy, comprising the following steps:

[0045] 1) The size of the titanium alloy test plate to be welded is 100×50×10mm, and the groove width is 12mm;

[0046] 2) Clean the groove area of the titanium alloy test plate, and use a carbide grinding head to grind the groove area to remove the oxide scale;

[0047] 3), use tin foil to cover the titanium alloy test plate treated in step 2), and then continue to inject argon gas with a purity of 99.99%;

[0048] 4) Under the condition of continuous protection of argon gas, use a steel fixture to connect the titanium alloy test plate coated in step 3) with the pulse power supply equipment, turn on the pulse power supply equipment, and set the pulse current frequency to 300Hz , the pulse width is 50μs, the current is 20000A, the sample preheating temperature is 500℃, and the energization time is 2min;

[0049]5)...

Embodiment 2

[0054] A pulse current-assisted method for pre-welding preheating and post-welding elimination of high-strength titanium alloy, comprising the following steps:

[0055] 1) The size of the titanium alloy test plate to be welded is 100×50×15mm, and the groove width is 12mm;

[0056] 2) Clean the groove area of the titanium alloy test plate, and use a carbide grinding head to grind the groove area to remove the oxide scale;

[0057] 3), use tin foil to cover the titanium alloy test plate treated in step 2), and then continue to inject argon gas with a purity of 99.99%;

[0058] 4) Under the condition of continuous protection of argon gas, use a steel fixture to connect the titanium alloy test plate coated in step 3) with the pulse power supply equipment, turn on the pulse power supply equipment, and set the pulse current frequency to 1000 Hz, the pulse width is 100μs, the current is 18000A, the sample preheating temperature is 550℃, and the energization time is 3min;

[0059]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com