A silicon steel sheet stacking device

A silicon steel sheet and fixing plate technology, applied in transformer/inductor parts, electrical components, manufacturing stator/rotor body, etc., can solve the problems of low production efficiency, long stacking time, inaccurate stacking, etc., to achieve convenient operation, Accurate and fast stacking, improving the effect of stacking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

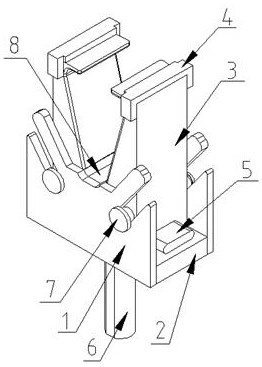

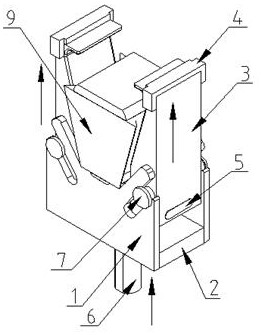

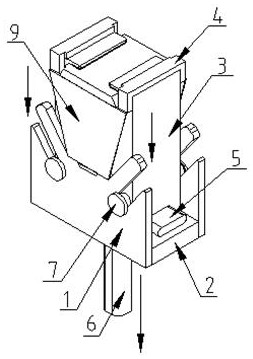

[0015] Such as figure 1 As shown, a device for stacking trapezoidal silicon steel sheets, the device includes two first fixed plates 1 of the same shape, a second fixed plate 2 and two shrinkage blocks 3 of the same shape provided with inclined surfaces, the first fixed plate 1 , The second fixed plate 2 is made of steel plate. The lower parts of the two first fixing plates 1 are welded and fixed on both sides of the end face of the second fixing plate 2 in parallel to form a fixing piece whose end face is a U-shaped groove. The upper surface of the first fixing plate 1 is made into a flat-bottomed V shape, which makes the structure more compact. A third fixing plate 8 is connected between the upper parts of the two first fixing plates 1 , and the upper surface of the third fixing plate 8 is flush with the end surface of the first fixing plate 1 . Both sides of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com