Display device and preparation method thereof

一种显示装置、显示区的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,能够解决外部水氧渗透、有机发光材料功能退化、影响显示装置寿命等问题,达到延长生命周期、增强密封性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

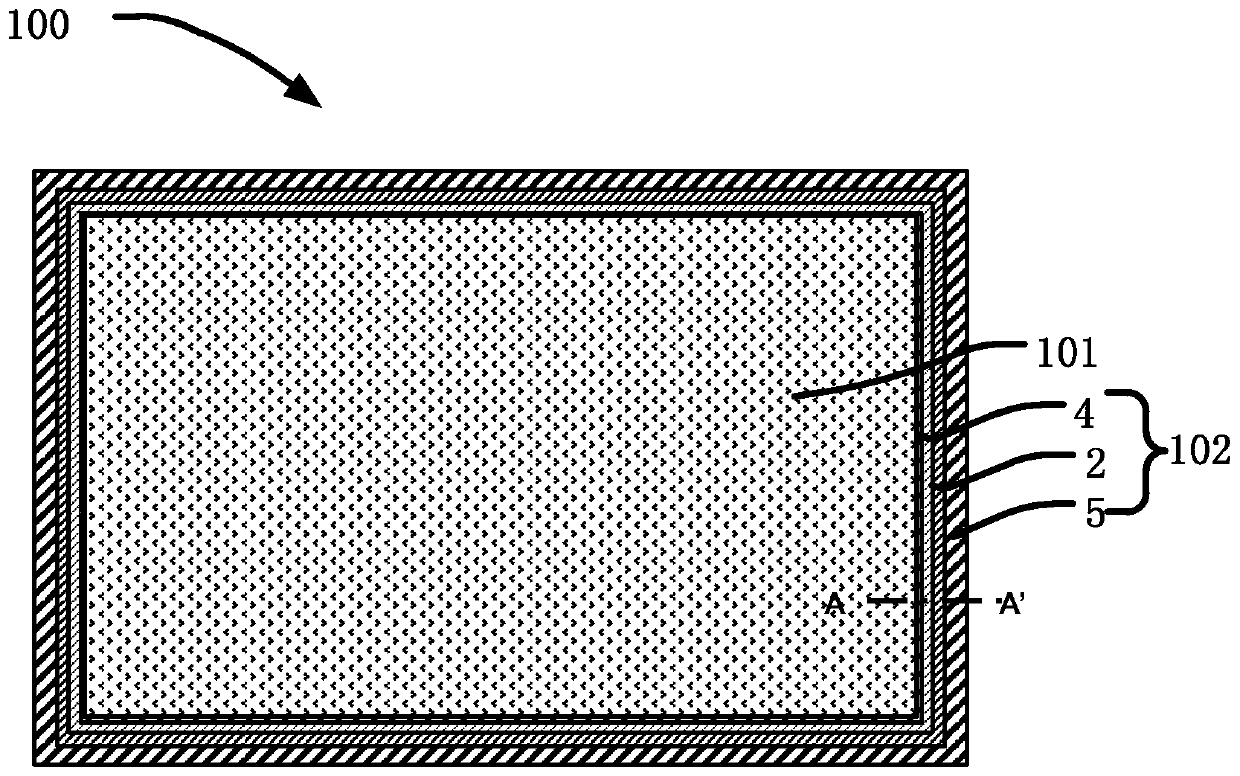

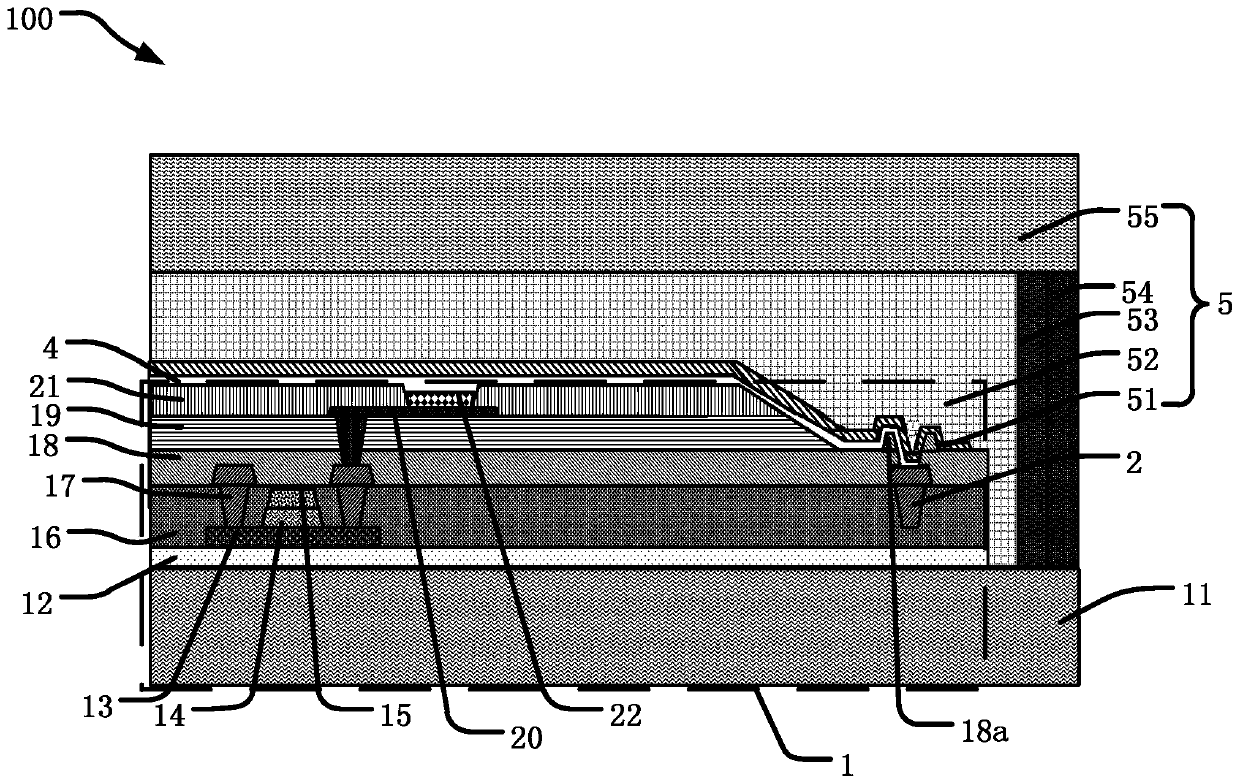

[0035] Such as Figure 1~2 As shown, this embodiment provides a display device 100 , including a display area 101 and a non-display area 102 , and the non-display area 102 surrounds the display area 101 .

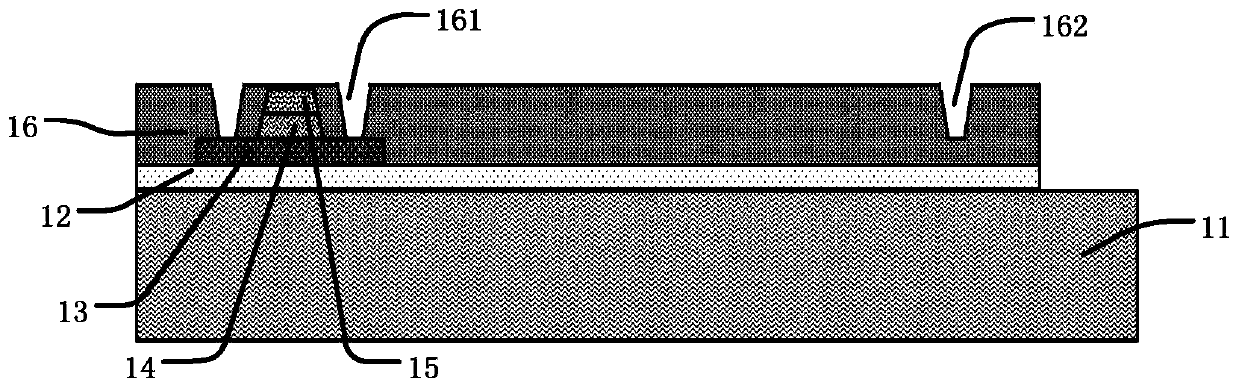

[0036] Such as figure 2 As shown, the display device 100 further includes a thin film transistor structure layer 1 , a ring metal layer 2 , a light emitting layer 3 , a first electrode 4 and an encapsulation layer 5 . The annular metal layer 2 is disposed in the thin film transistor structure layer 1 , and the annular metal layer 2 is located in the non-display area 102 and surrounds the display area 101 . The light emitting layer 3 is disposed on the thin film transistor structure layer 1 and located in the display area 101 . The first electrode 4 is disposed above the light-emitting layer 3 , extends from the display area 101 to the surface of the ring-shaped metal layer 2 in the non-display area 102 , and completely covers the surface of the ring-shaped metal layer 2 ...

Embodiment 2

[0083] This embodiment provides a display device and a manufacturing method thereof, which includes most of the technical features of Embodiment 1, the difference being that the first annular metal layer is disposed on the dielectric layer and protrudes from the blunt The layer can also provide a good contact surface for the first electrode, so that the first electrode is fixedly connected to the annular metal layer; second, the display device includes at least one first groove, from which The pixel definition layer extends to the surface of the passivation layer to cut off the water vapor transmission path; thirdly, the packaging layer includes a water-blocking and moisture-absorbing adhesive layer and a metal foil instead of a cover layer and a cover plate, and can also Realize the effect of blocking water and oxygen.

[0084] Such as Figure 5 As shown, the display device 100 further includes a thin film transistor structure layer 1 , a ring metal layer 2 , a light emittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com