Rotary side-driven magnetic engine

An engine and rotary technology, applied in the direction of electromechanical devices, electrical components, etc., can solve problems such as cylinder block damage, large engine vibration, and engine weakness, and achieve the effect of simplifying the structure of the transmission, ensuring strong torque, and reducing production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

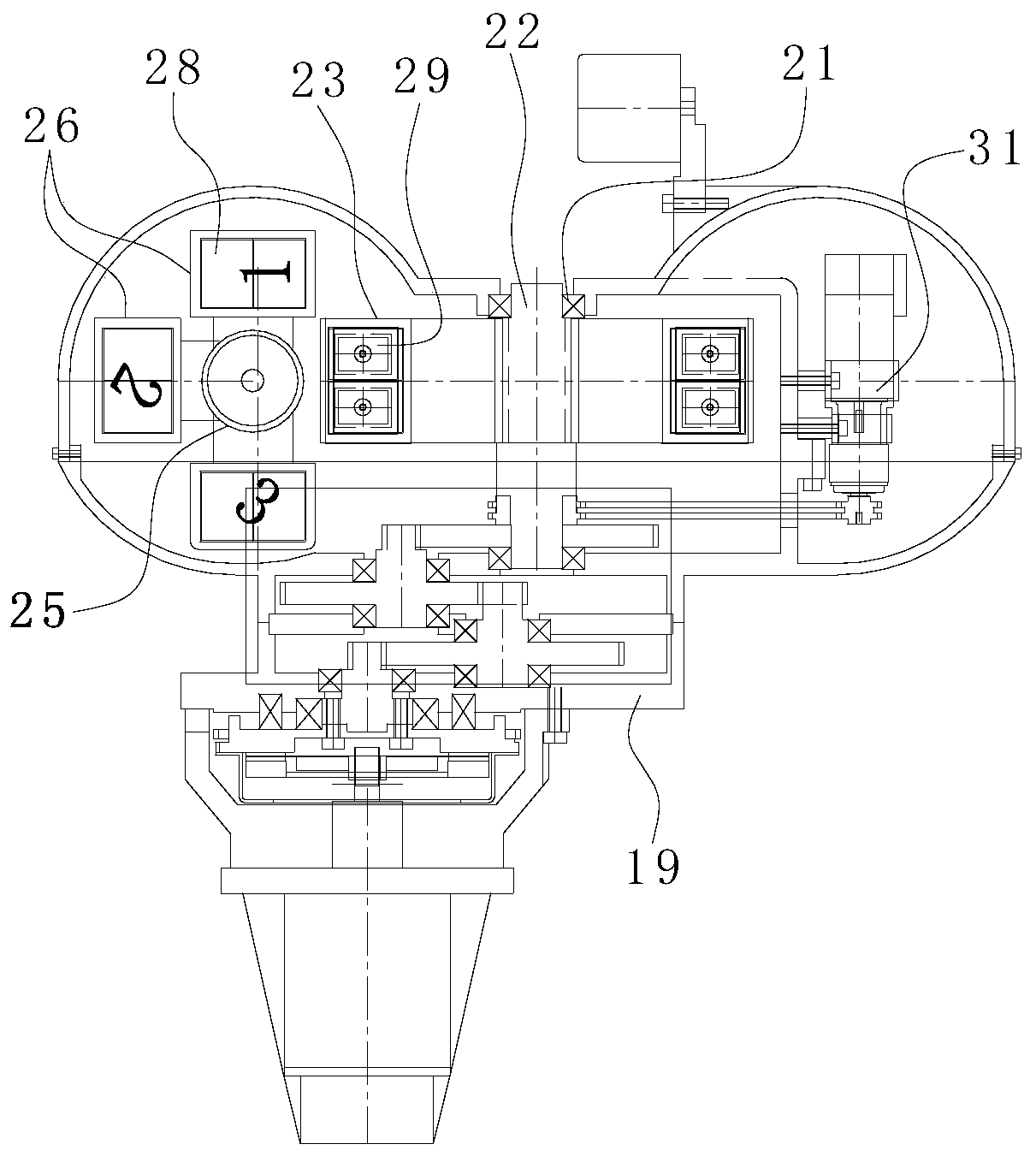

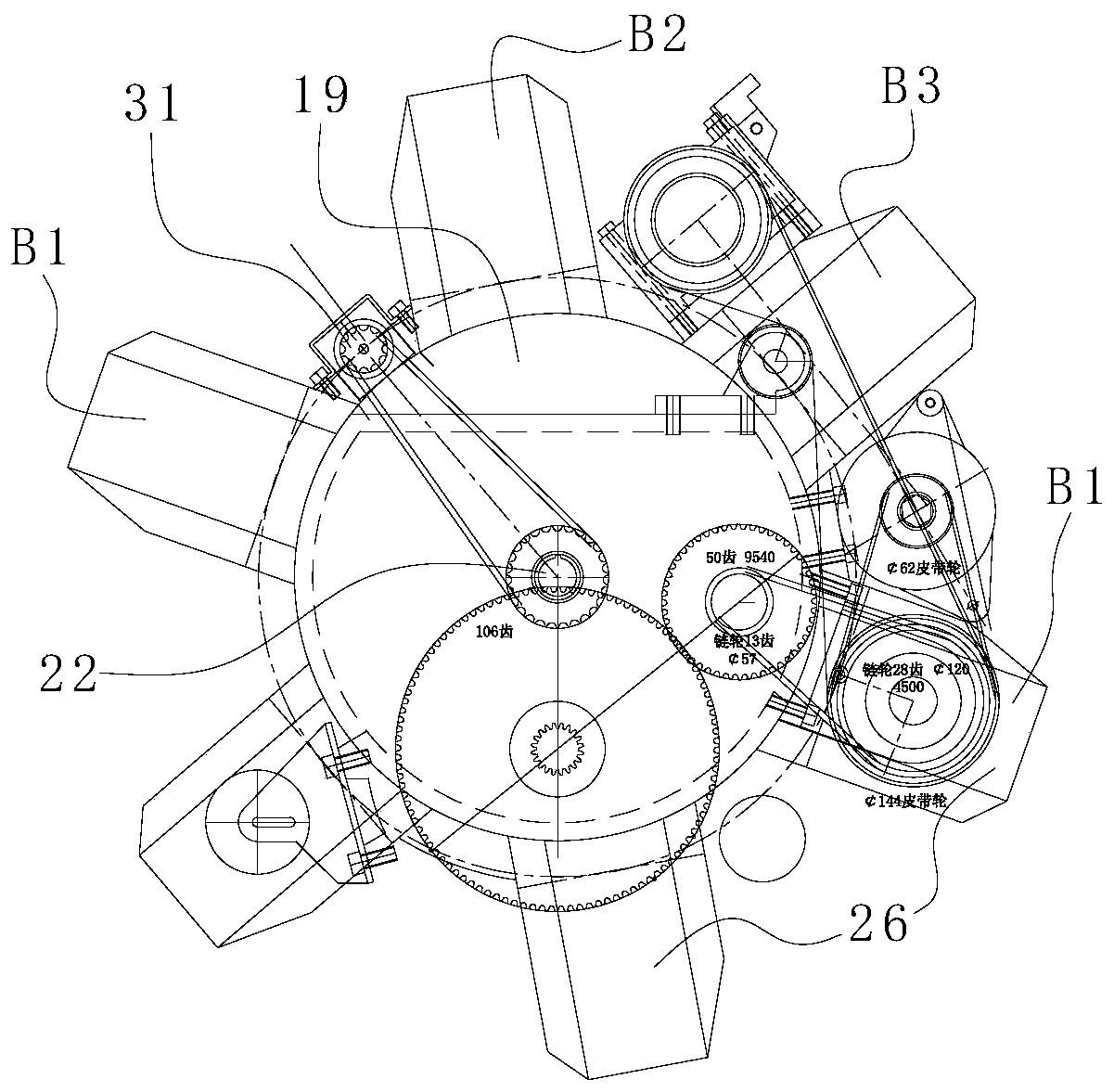

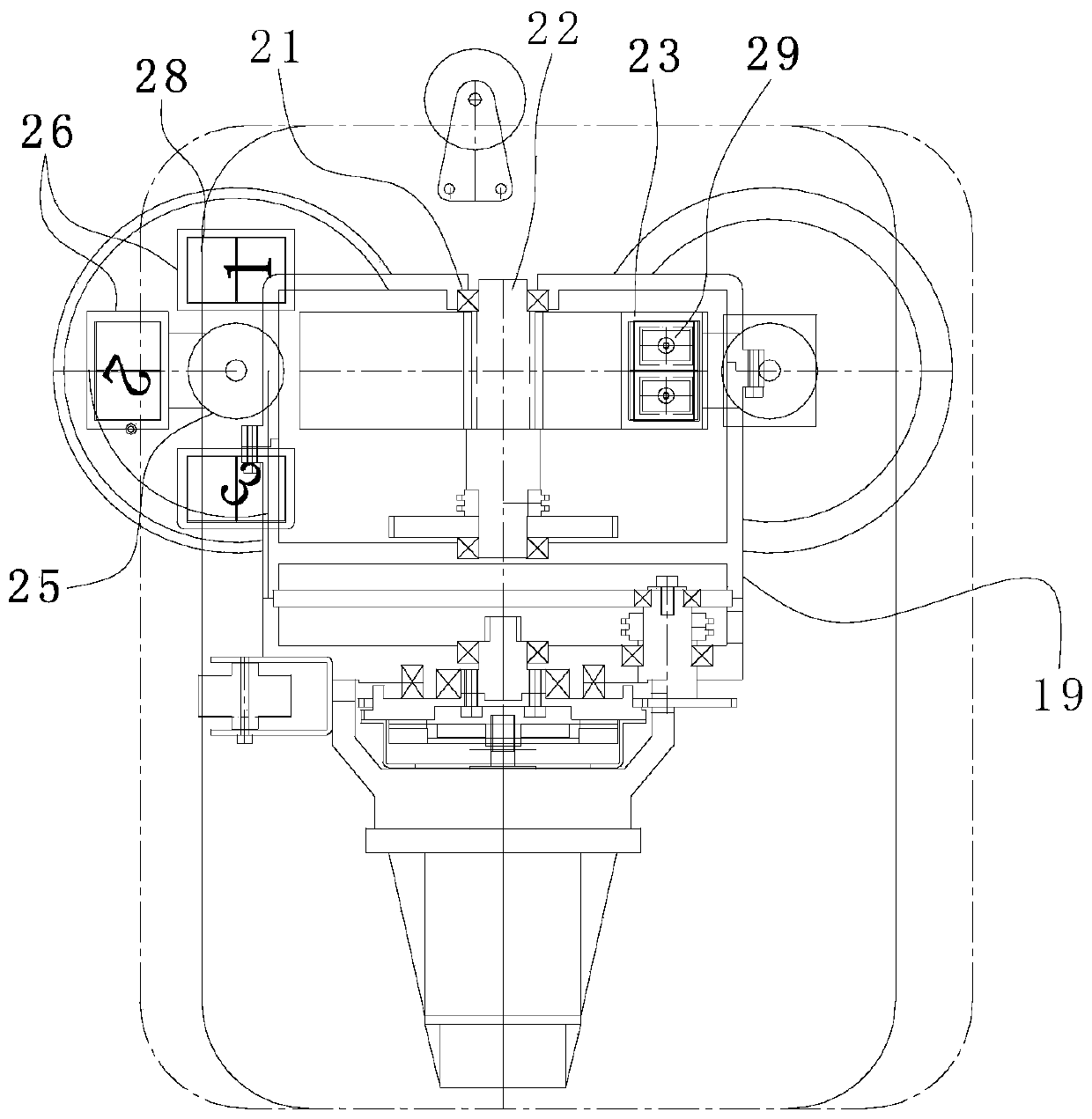

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, a six-wheel drive and four-rotation side-drive magnetic motor of the present invention is shown, which includes a base 19 and a rotating main shaft 22 connected to the base 19 through bearings 21, and four pieces are installed around the base at equal angles The inner magnets 23 on the circumferential side of the rotating main shaft 22, 6 groups of outer magnetic blocks 26 and the driving device for driving the corresponding outer magnetic blocks 26 to rotate along the direction perpendicular to the axis of the drive shaft of the rotating main shaft 22; The magnet block 26 cuts between the two inner magnets 23 in turn and repels each other with the back surface of the front inner magnet 23, the angular position difference between the adjacent inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com