Method for making horizontal air outlet directions of two sides of ion bar consistent in static elimination performance under same vertical distance

A vertical distance, ion bar technology, applied in the direction of static electricity, electrical components, etc., can solve the problems such as the inability to increase the power dissipation speed, the output air flow state is disordered, the power dissipation time is inconsistent, etc., to achieve rapid static elimination effect, reduce airflow consumption, The effect of optimizing the outlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

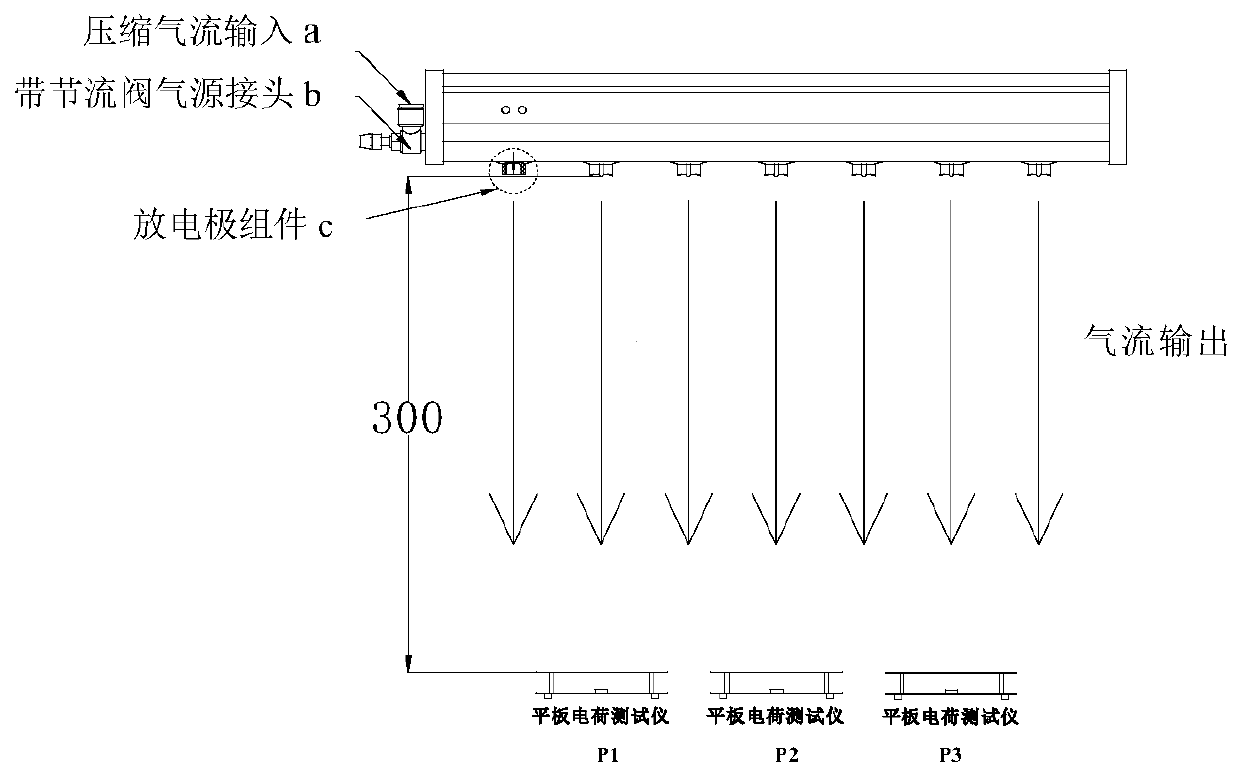

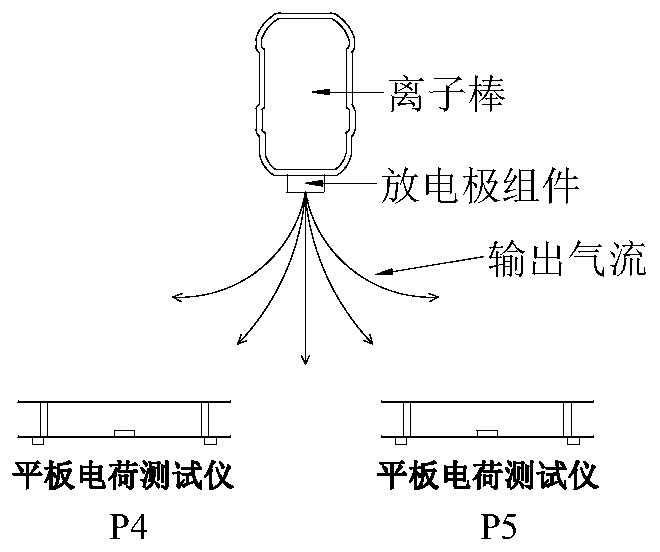

[0089] The discharge electrode assembly that will adopt technical solution of the present invention to manufacture (see Figure 8 shown in ) with the existing discharge electrode assembly (see Figure 9, Figure 10 Shown in) is carried out comparative test, and the comparative test data that obtains is shown in Table 1:

[0090] Table 1, comparative test data:

[0091]

[0092] From the above comparative data, it can be seen that:

[0093] 1. Under the same test conditions, the pressure drop of the ion rod using this technical solution is significantly smaller than that of the comparison product. It can be seen that after adopting this technical solution, the pressure loss of the ion rod is smaller.

[0094] 2. Under the same test conditions, the power dissipation speed of the sample stick of this technical solution is obviously faster than that of the comparison product.

[0095] 3. Under the same test conditions, the consistency and stability of the balanced voltage of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com