Gas roller for thin film traction

A technology of thin film and air roller, which is applied in the direction of thin material processing, coiling, transportation and packaging, etc. It can solve the problems of uneven air outlet from air holes, affecting the transmission and quality of thin-walled tubes, and achieves uniform air output and improved Production quality, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

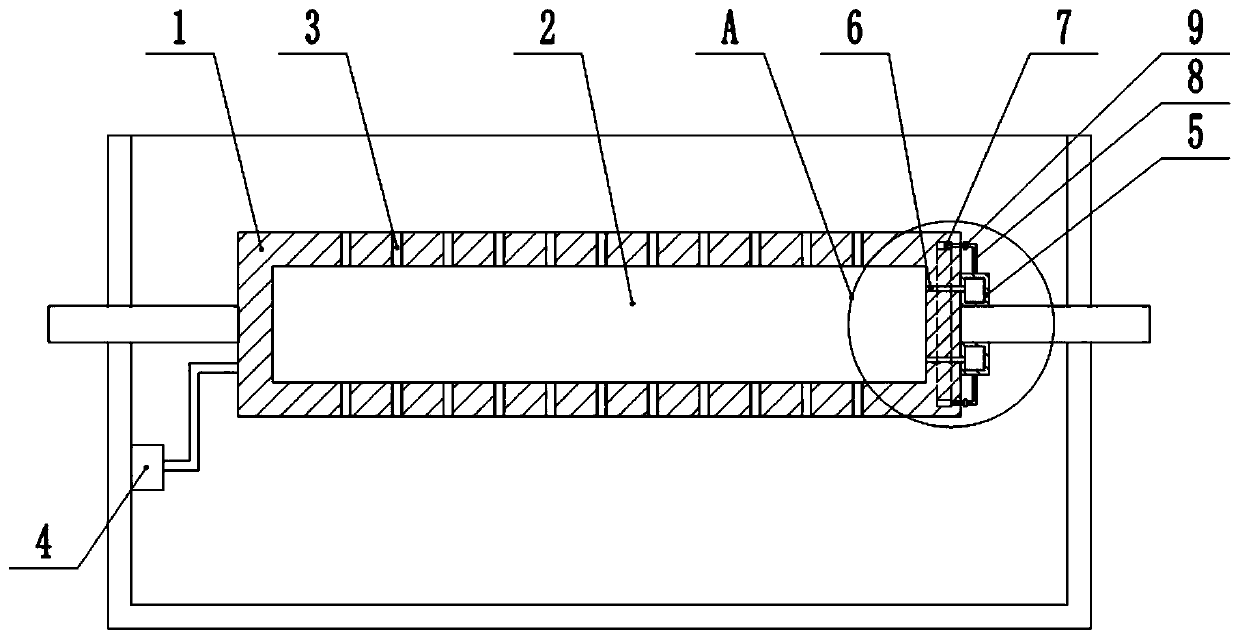

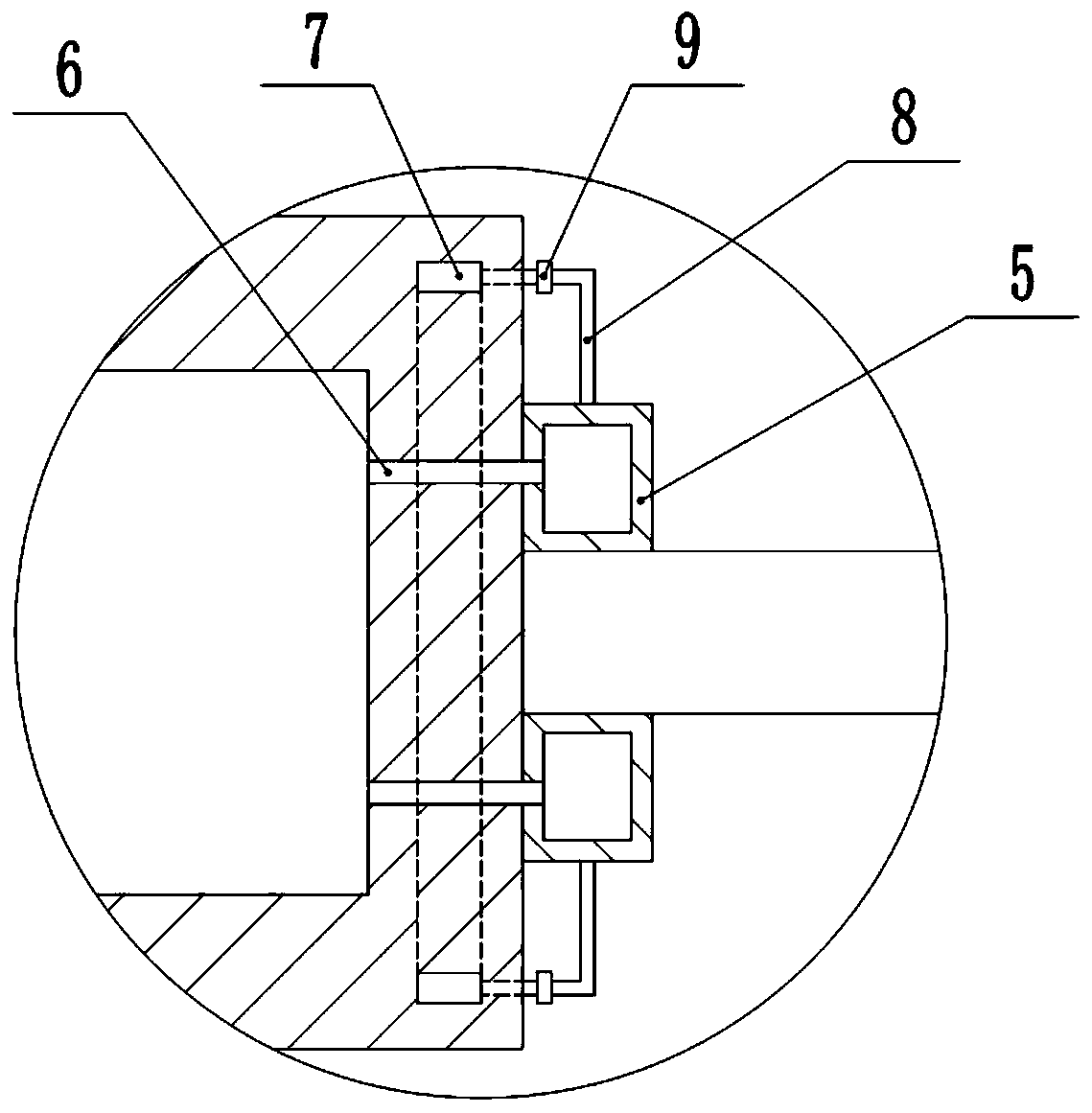

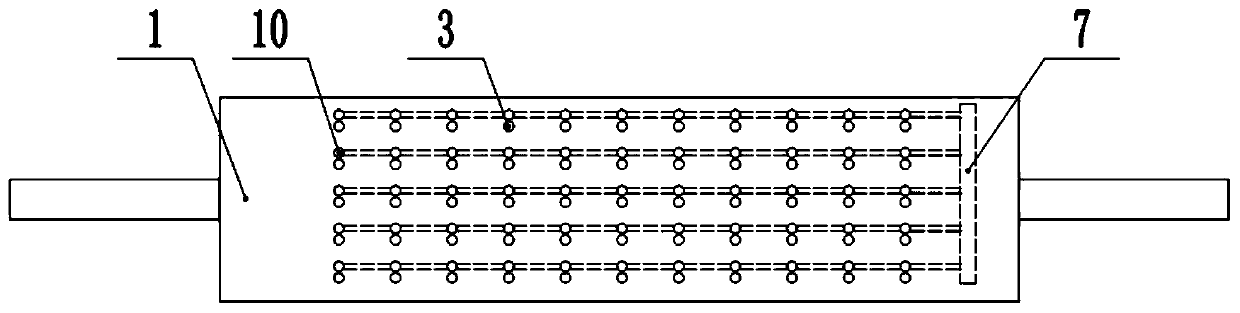

[0027] Embodiment one is basically as attached Figure 1 to Figure 4 Shown:

[0028] The air roller for film traction includes a roller body 1 with a cavity 2 in the roller body 1, and an air hole 3 connecting the cavity 2 with the outside world on the roller body 1. The left end of the roller body 1 is connected with a gas supply to the cavity 2. The air supply mechanism, in the present embodiment, the air supply mechanism is blower 4. The right end of the roller body 1 is provided with an air replenishing mechanism, which includes a cavity 5 fixed on the roller body 1, and the right end of the roller body 1 is provided with a drainage hole 6 communicating with the cavity 5, and the diameter of the drainage hole 6 is smaller than The diameter of the air holes 3 and the drainage holes 6 are evenly distributed in the circumferential direction on the roller body 1 . There is an annular cavity 7 inside the roller body 1, and a conduit 8 is connected between the annular cavity 7...

Embodiment 2

[0030] Embodiment two is basically as attached Figure 5 Shown:

[0031] The difference between this embodiment and Embodiment 1 is that it also includes a driving mechanism for driving the roller body 1 to reciprocate along the length direction of the roller body 1. The driving mechanism includes piston cylinders 11 arranged at both ends of the roller body 1. A piston 12 is slidingly connected, and a piston rod 13 is fixedly connected to the piston 12. The end of the piston rod 13 away from the piston cylinder 11 is coaxially fixedly connected with the roller body 1. The piston cylinder 11 is provided with an air inlet 3, and the piston cylinder 11 is also provided with A pressure valve 15 is installed, and an inflation mechanism is connected to the air inlet 3 . The inflation mechanism includes an air duct 16 communicated with the air inlet 3, and the air duct 16 is equipped with a valve 17 and a one-way valve 18 leading to the piston cylinder 11, and the air duct 16 at bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com