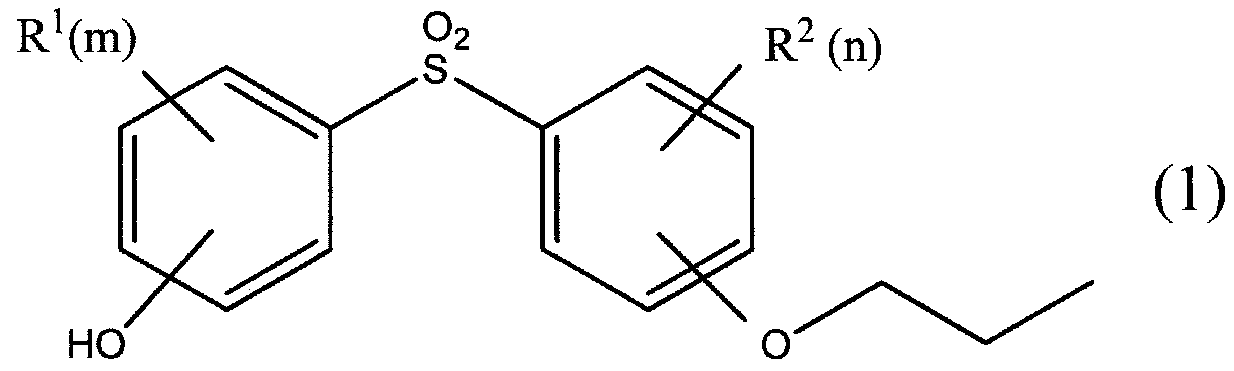

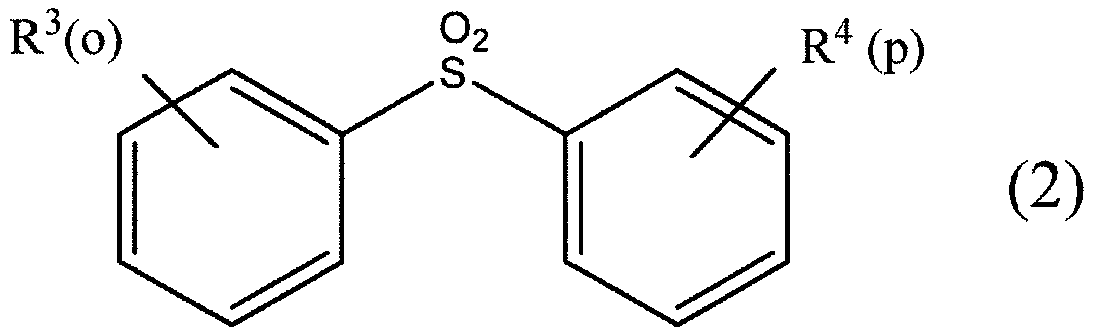

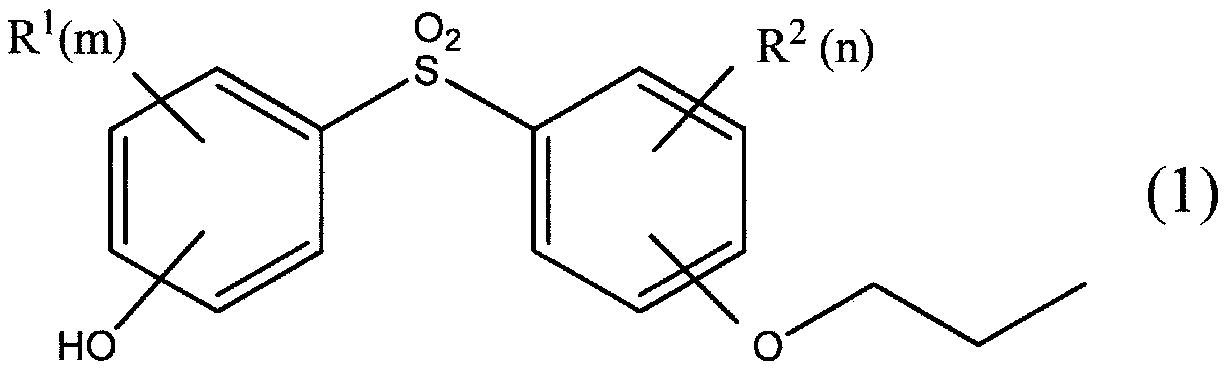

Thermosensitive recording material and laminate

A heat-sensitive recording material and technology for heat-sensitive recording, applied in the direction of copying/marking methods, printing, printing devices, etc., to achieve the effects of good preservation, good contrast, and good color sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-3 and comparative example 1-1~1-5

[0138] The following Examples 1-1 to 1-3 and Comparative Examples 1-1 to 1-5 were performed in order to confirm the difference in the effect by the compounding quantity of compound (1) and compound (2).

Embodiment 1-1

[0140] The respective liquids were mixed in the following ratios to prepare a coating liquid for a thermosensitive recording layer.

[0141] Liquid A: 18.87 parts

[0142] Liquid B: 0.02 parts

[0143] Liquid C: 10.00 parts

[0144] Liquid D: 18.89 parts

[0145] Liquid E: 29.75 parts

[0146] Liquid F: 9.95 parts

[0147] Liquid G: 32.64 parts

[0148] Next, when the dry weight of the thermosensitive recording layer becomes 6g / m 2 In the above method, the coating solution of the above-mentioned composition for the thermosensitive recording layer is coated on the paper provided with a bottom layer on one side of high-quality paper as a support, and dried by a blower dryer to form a thermosensitive recording layer. Apply 1kgf / cm to it with a super calender 2 The pressure was smoothed to obtain a thermosensitive recording material (laminated body).

Embodiment 1-2

[0150] Except having changed A liquid into 18.80 parts, and B liquid into 0.09 parts, it carried out similarly to Example 1-1, and manufactured the thermosensitive recording material (laminated body).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com