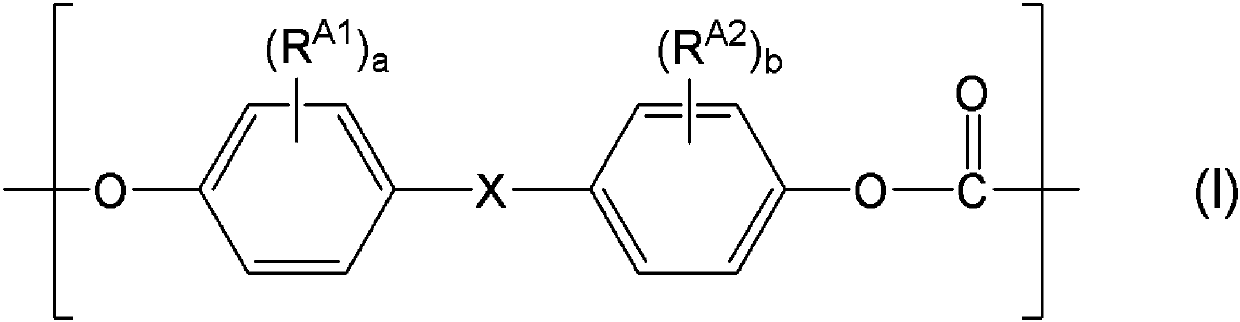

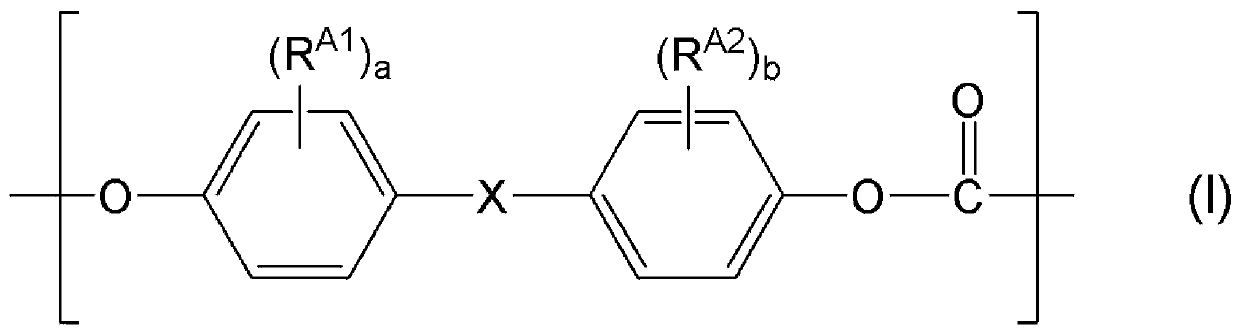

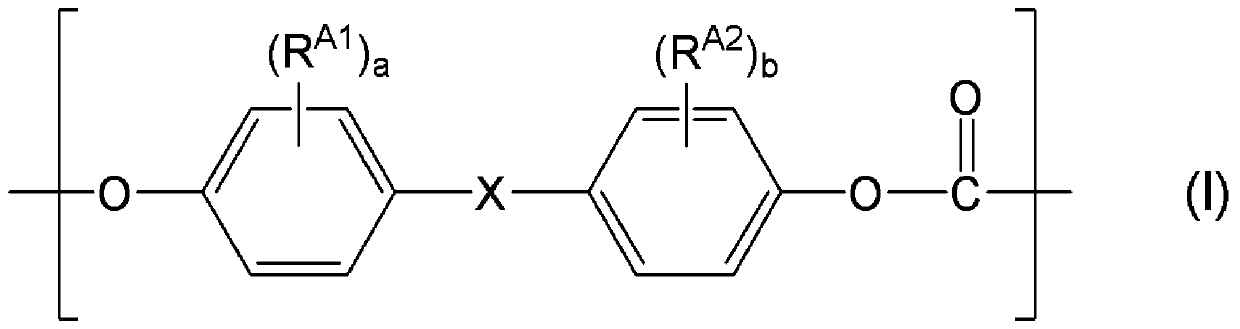

Aromatic polycarbonate resin composition and optical molded article

A polycarbonate resin, aromatic technology, applied in the field of optical molded products, can solve the problems of mechanical properties such as impact resistance decline, color deterioration caused by coloring, etc., and achieve the effect of excellent long-term heat resistance and long-term humidity and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~25 and comparative example 1~12

[0189] After mixing the components in the proportions shown in Table 1 or Table 2, use a single-screw extruder with a screw diameter of 40 mm (manufactured by Tanabe Plastic Machinery Co., Ltd. "VS-40") with a vent at a temperature of 250 Melt-kneading was carried out at ℃, and pellets were obtained by strand cutting. After drying the obtained pellets at 110° C. for 5 hours, preparation of a molded body and various evaluations were performed by the following methods.

[0190] [Initial YI value of molded body]

[0191] The above-mentioned dried pellets were molded into 50 mm by injection molding machine ("ES1000" manufactured by Nissei Plastic Industry Co., Ltd.) under conditions of cylinder temperature 320°C, mold temperature 80°C, and cycle time 50 seconds. A flat test piece (molded article (1)) of ×90 mm×thickness 5 mm.

[0192] For the obtained test piece, the YI value was measured under the conditions of a C light source and a 2-degree field of view using a spectrophotom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com