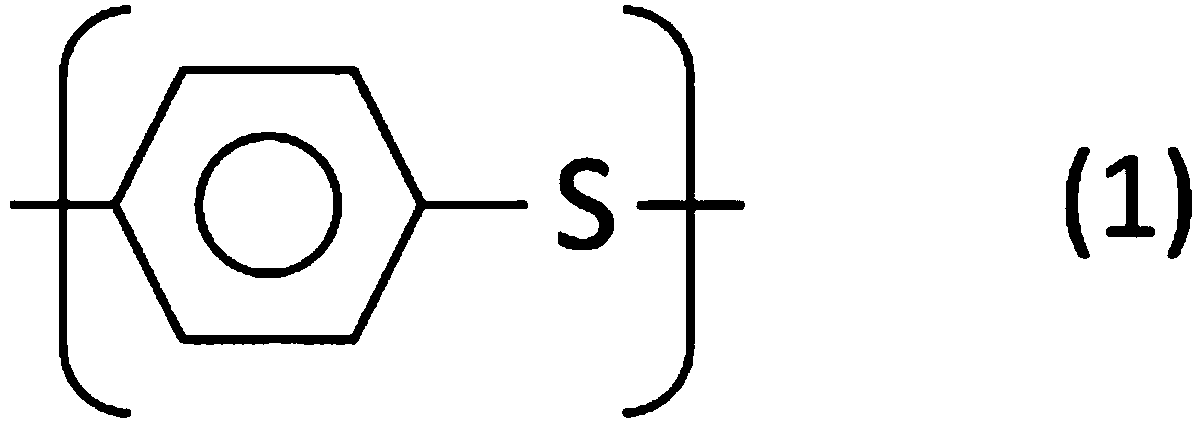

polyphenylene sulfide fiber

A polyphenylene sulfide fiber, fiber diameter technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, separation methods, etc., can solve the problems of fiber structure stability, inhibit strength reduction, etc., and achieve fiber structure changes. Small size, small strength reduction, and excellent long-term heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

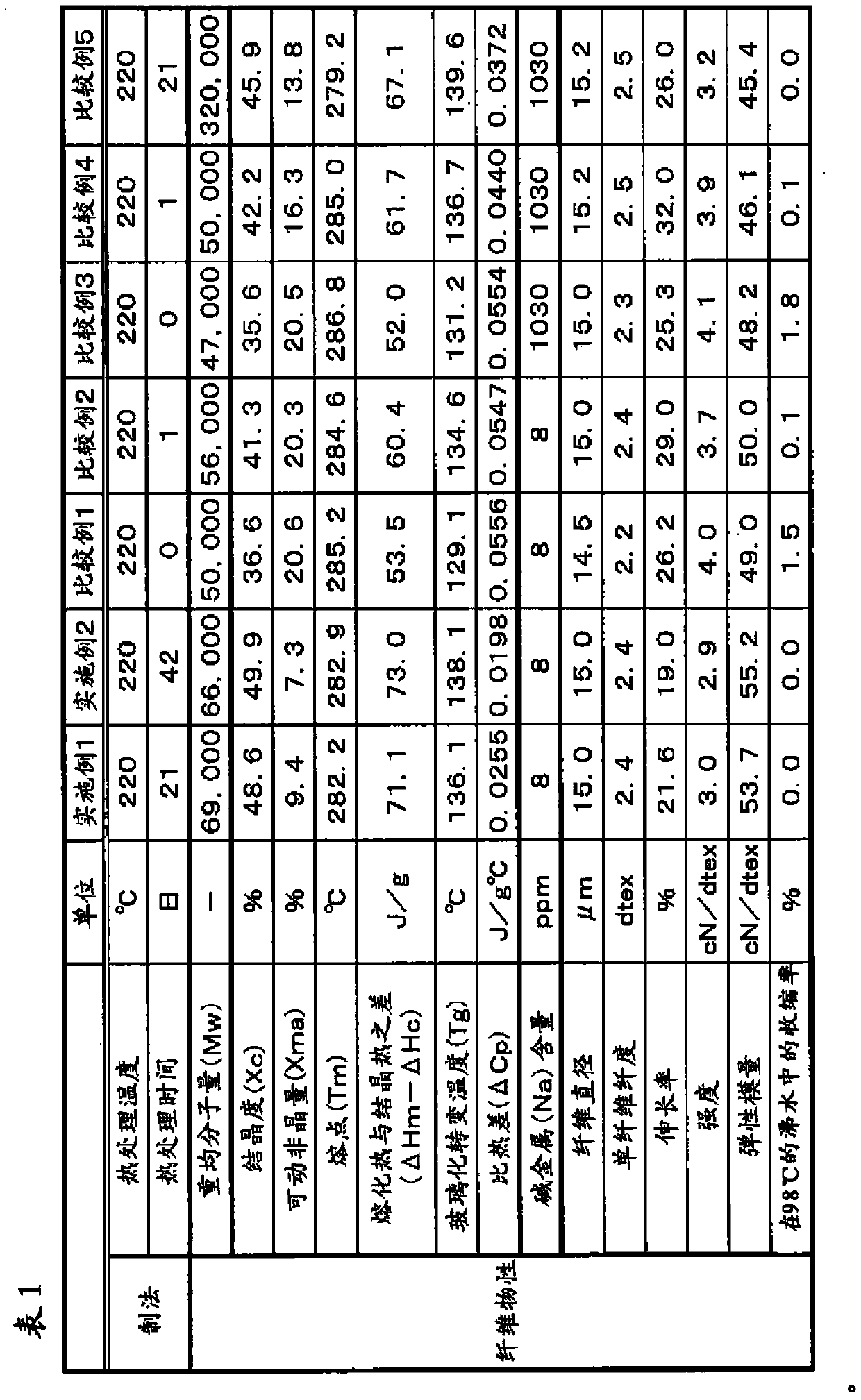

[0060] Hereinafter, the present invention will be described more specifically using examples. In addition, each characteristic value in an Example was calculated|required by the following method.

[0061] A. Weight average molecular weight

[0062] The weight average molecular weights of the PPS polymer and the PPS fiber were calculated in terms of polystyrene by gel permeation chromatography (GPC), which is one type of size exclusion chromatography (SEC). The measurement conditions of GPC are as follows.

[0063] Device: SSC-7100 manufactured by Senshu Science Co., Ltd.

[0064] Column name: GPC3506 manufactured by Senshu Scientific Co., Ltd.

[0065] Eluent: 1-Chloronaphthalene

[0066] Detector: Differential Refractive Index Detector

[0067] Column temperature: 210°C

[0068] Pre-heating bath temperature: 250°C

[0069] Pump thermostat temperature: 50°C

[0070] Detector temperature: 210°C

[0071] Flow: 1.0mL / min

[0072] Sample injection volume: 300 μL (slurry ...

reference example 1

[0094]

[0095] In a 70-liter autoclave with a stirrer, 8.27kg (70.0 moles) of 47.5% sodium hydrosulfide, 2.96kg (71.0 moles) of 96% sodium hydroxide, N-methyl-2-pyrrolidone (hereinafter, sometimes referred to as 11.44kg (116 moles) of NMP), 1.72kg (21.0 moles) of sodium acetate, and 10.5kg of ion-exchanged water, slowly heated to about 240°C for about 3 hours under normal pressure while feeding nitrogen gas, and rectified Tower, 14.8kg of water and 280g of NMP were distilled off, and then the reaction vessel was cooled to 160°C. In addition, 0.02 mol of hydrogen sulfide flew out of the system with respect to 1 mol of the sulfur component charged during this dehydration operation.

[0096] Next, 10.3 kg (70.3 mol) of p-dichlorobenzene and 9.00 kg (91.0 mol) of NMP were added, and the reaction container was sealed under nitrogen gas. While stirring at 240 rpm, the temperature was raised to 270° C. at a rate of 0.6° C. / minute, and maintained at this temperature for 140 minute...

reference example 2

[0103]

[0104] The PPS oligomer containing cyclic PPS obtained in Reference Example 1 was charged into an autoclave equipped with a stirrer, the atmosphere was replaced with nitrogen, and the temperature of the autoclave was raised to 340° C. over 1 hour. During the temperature rise, when the PPS oligomer melted, the rotation of the stirrer was started, and the melt heating was performed for 180 minutes while stirring at a rotation speed of 10 rpm. Then, the resin was taken out from the discharge hole in the shape of a gut by nitrogen gas pressure, and the gut was pelletized. The solid matter obtained as described above was dried with hot air at 130° C. to obtain a dried PPS resin (A).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com