Micro device and preparation method thereof

A micro-device and semiconductor technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of waste of efficiency, large luminous angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

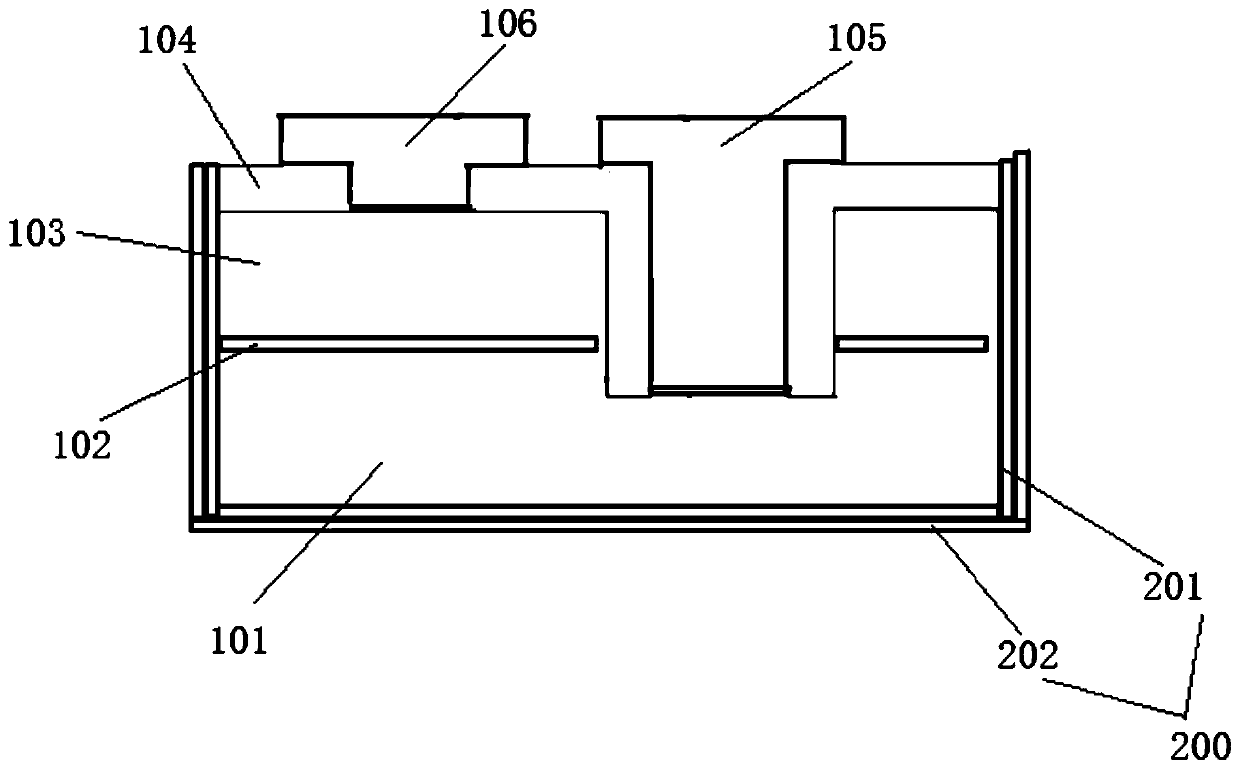

[0055] Based on the above-mentioned micro-device, the present invention also provides a preparation method of a micro-device, such as Figure 7 Shown is a flow chart of a method for preparing a micro-device of the present invention. Described preparation method comprises:

[0056] S1. A multi-quantum well layer is arranged between the first semiconductor layer and the second semiconductor layer;

[0057] The first semiconductor layer can be doped with a pentavalent element such as phosphorus in a pure semiconductor material, such as gallium nitride (GaN), to form the above-mentioned first semiconductor layer. In the first semiconductor layer, free electrons are many, Holes have few electrons, mainly conduct electricity by free electrons, the higher the concentration of many electrons (free electrons), the stronger the conductivity of the first semiconductor layer; in the same way, the second semiconductor layer can be in a pure semiconductor material, such as nitride Gallium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com