Automatic wax spraying system and method

A wax spraying and automatic technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of inability to guarantee the consistent quality of the brick surface, the adjustment effect varies from person to person, and the effect of the brick surface is unqualified, so as to accurately control the surface quality of the brick. , to avoid time lag, the effect of consistent brick surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

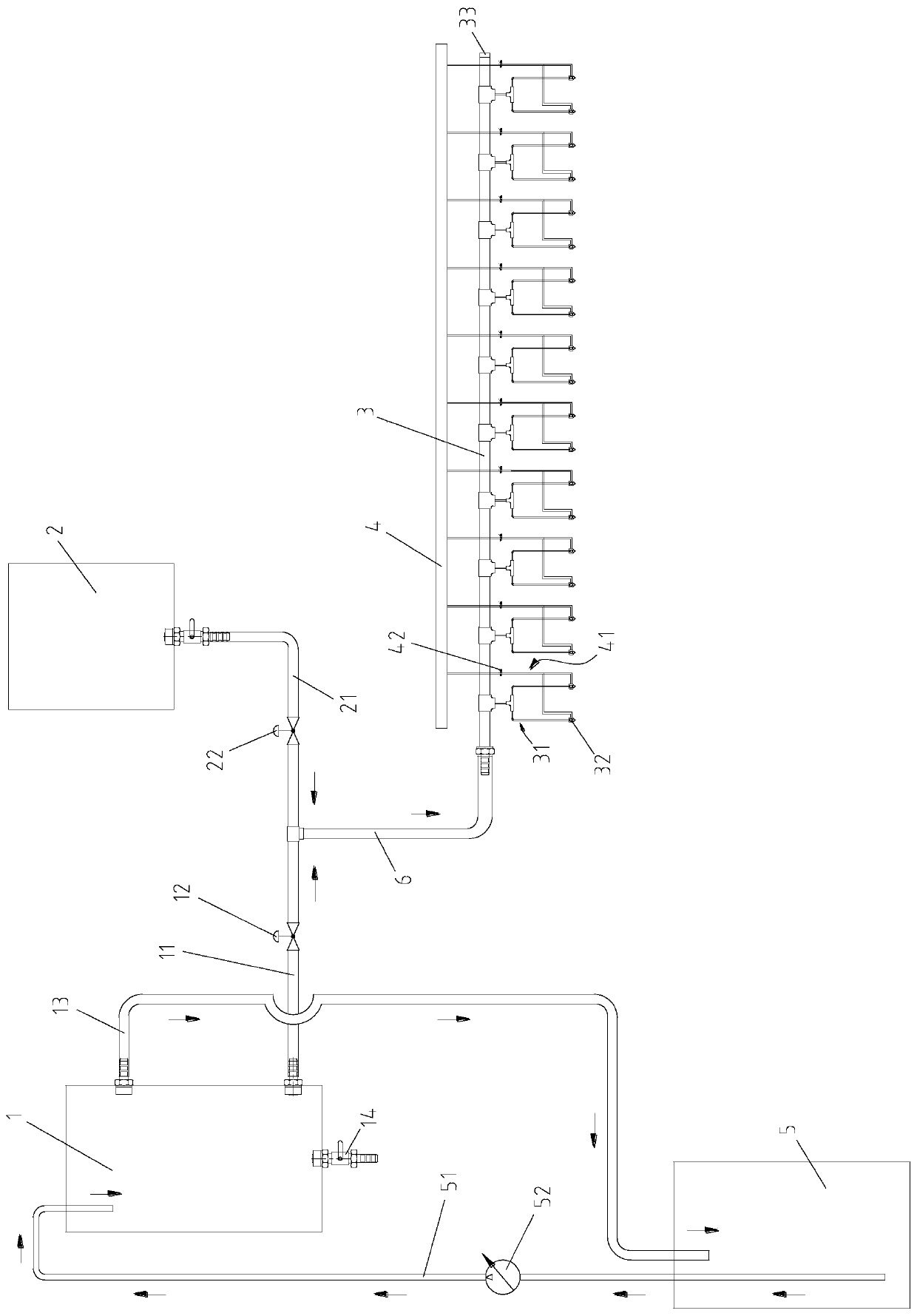

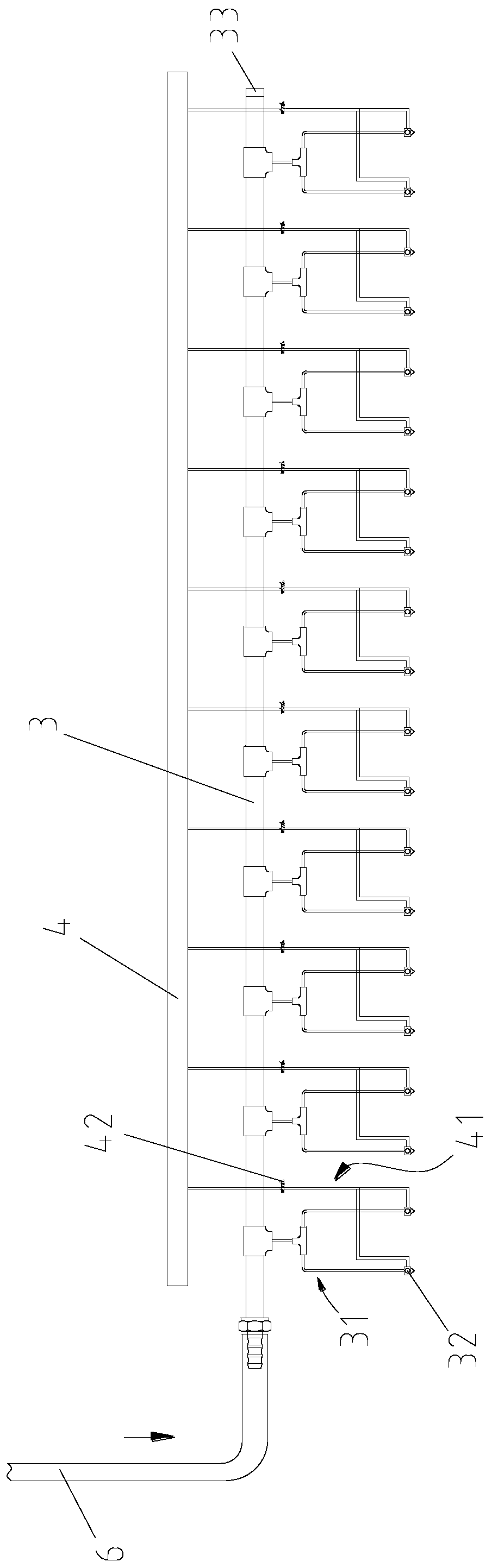

[0023] See figure 1 , figure 2 , The automatic wax spraying system comprises a waxing water storage container 1, a clear water storage container 2, a wax water main pipe 3, a high-pressure gas pipe 4 and a control system (not shown). The height of the wax water main pipe 3 is lower than that of the wax water storage container 1 and the clear water storage container 2. The bottom of the wax water storage container 1 is provided with a wax water outlet, and the wax water outlet and the wax water main pipe 3 pass through The wax water branch pipe 11 is connected, and the wax water branch pipe 11 is connected with a first pneumatic ball valve 12 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com