A processing method for improving the grain size of the harmonic reducer flex wheel

A harmonic reducer and processing method technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of flexible splines being easily damaged, flexible splines with large alternating loads, etc., and achieve large strong plastic product and small grain size , the effect of high grain size grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

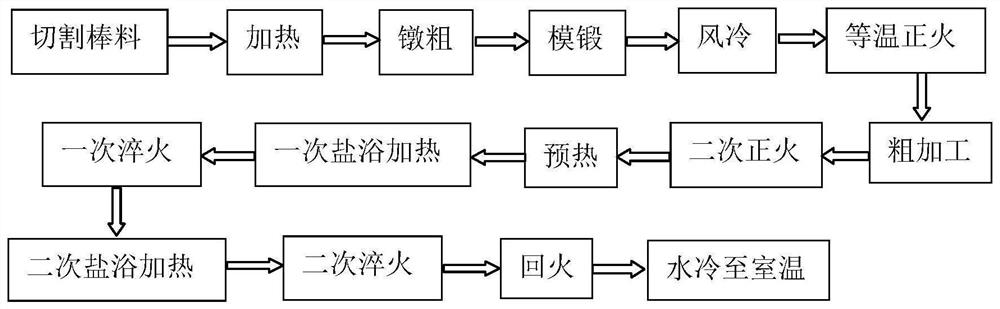

[0103] A processing method for increasing the grain size of a harmonic reducer flexwheel, comprising the following steps:

[0104] (1) Cut bar stock. The bar is made of 40CrNiMoA medium carbon low alloy steel.

[0105](2) Heating. Electromagnetic induction heating is adopted, the heating time is 9s, and the heating temperature is 1120°C.

[0106] (3) Upsetting. The upsetting temperature is 1120°C.

[0107] (4) Die forging. The initial forging temperature is 1110°C, the final forging temperature is 880°C, and the wall thickness of the forging is 7.5mm.

[0108] (5) Air cooling. After the die forging is finished, place the workpiece on the mesh belt and cool it quickly with a fan. The air cooling speed, that is, the cooling rate of the workpiece is 25°C / s. When it is cooled to about 500°C, it is placed in the air for free cooling.

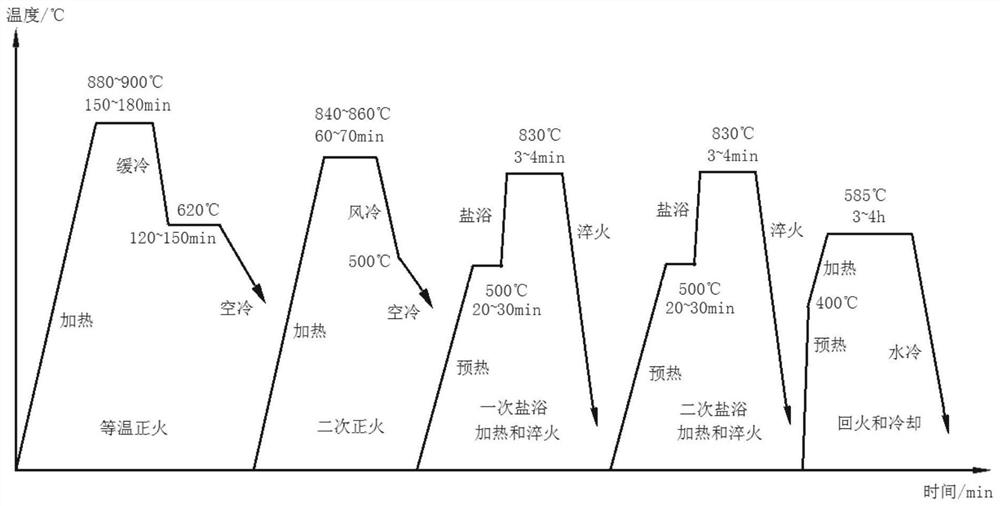

[0109] (6) Isothermal normalizing. Heat the workpiece to 880°C for 180 minutes, then place the workpiece in a slow cooling tank for slow coo...

Embodiment 3

[0122] A processing method for increasing the grain size of a harmonic reducer flexwheel, comprising the following steps:

[0123] (1) Cut bar stock. The bar is made of 40CrNiMoA medium carbon low alloy steel.

[0124] (2) Heating. Electromagnetic induction heating is adopted, the heating time is 11s, and the heating temperature is 1150°C.

[0125] (3) Upsetting. The upsetting temperature is 1145°C.

[0126] (4) Die forging. The initial forging temperature is 1130°C, the final forging temperature is 918°C, and the wall thickness of the forging is 7.5mm.

[0127] (5) Air cooling. After die forging, place the workpiece on the mesh belt and cool it quickly with a fan. The air cooling speed, that is, the cooling rate of the workpiece is 30°C / s. After cooling to about 500°C, place it in the air for free cooling.

[0128] (6) Isothermal normalizing. Heat the workpiece to 900°C for 150 minutes, then place the workpiece in a slow cooling tank for slow cooling, and when cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com