Real-time monitoring device for convex surface grinding frequency of piezoelectric quartz wafer

A piezoelectric quartz, real-time monitoring technology, applied in grinding devices, grinding machine tools, parts of grinding machine tools, etc., can solve the problem of inability to monitor the grinding frequency of quartz wafers, and achieve the effect of real-time monitoring and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

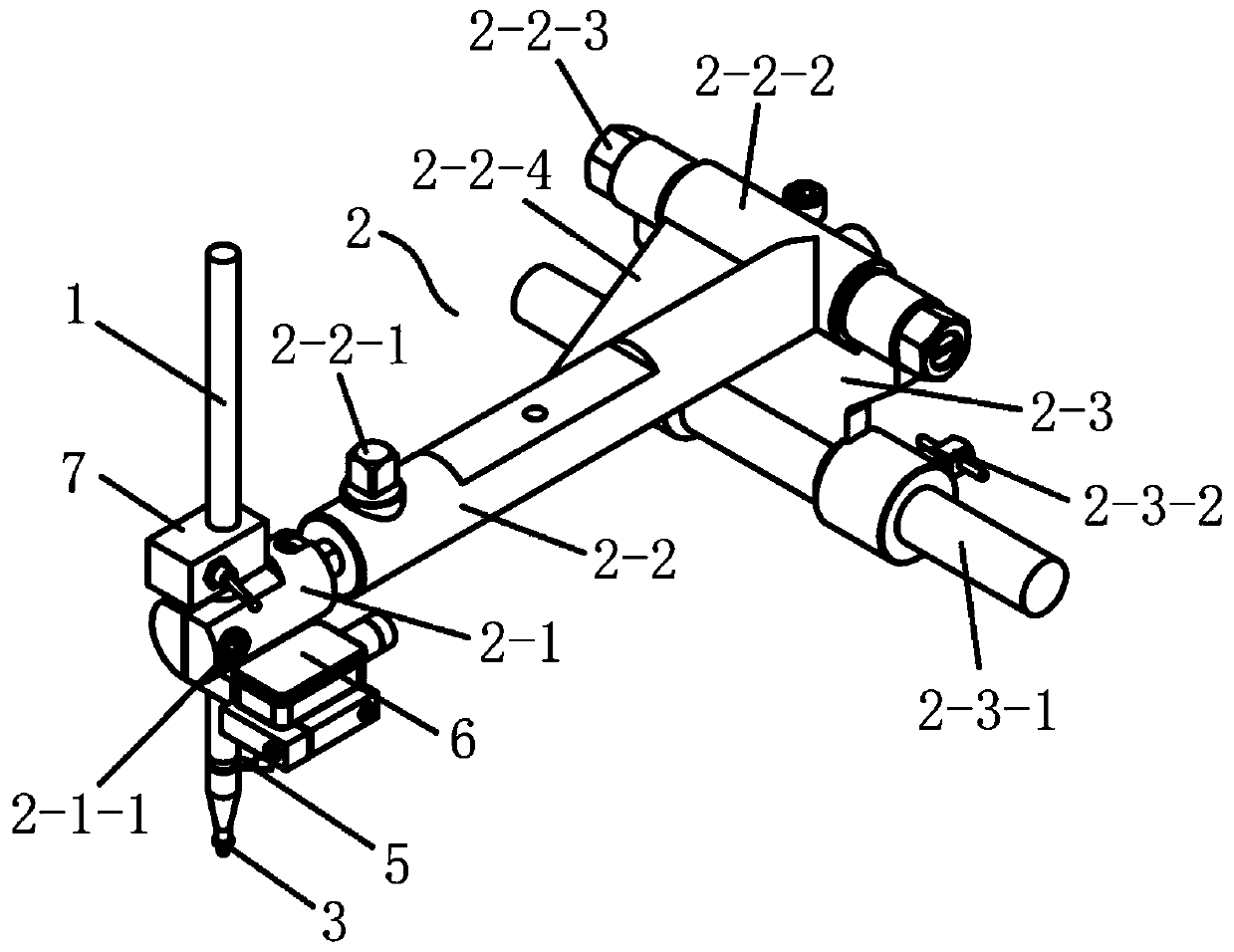

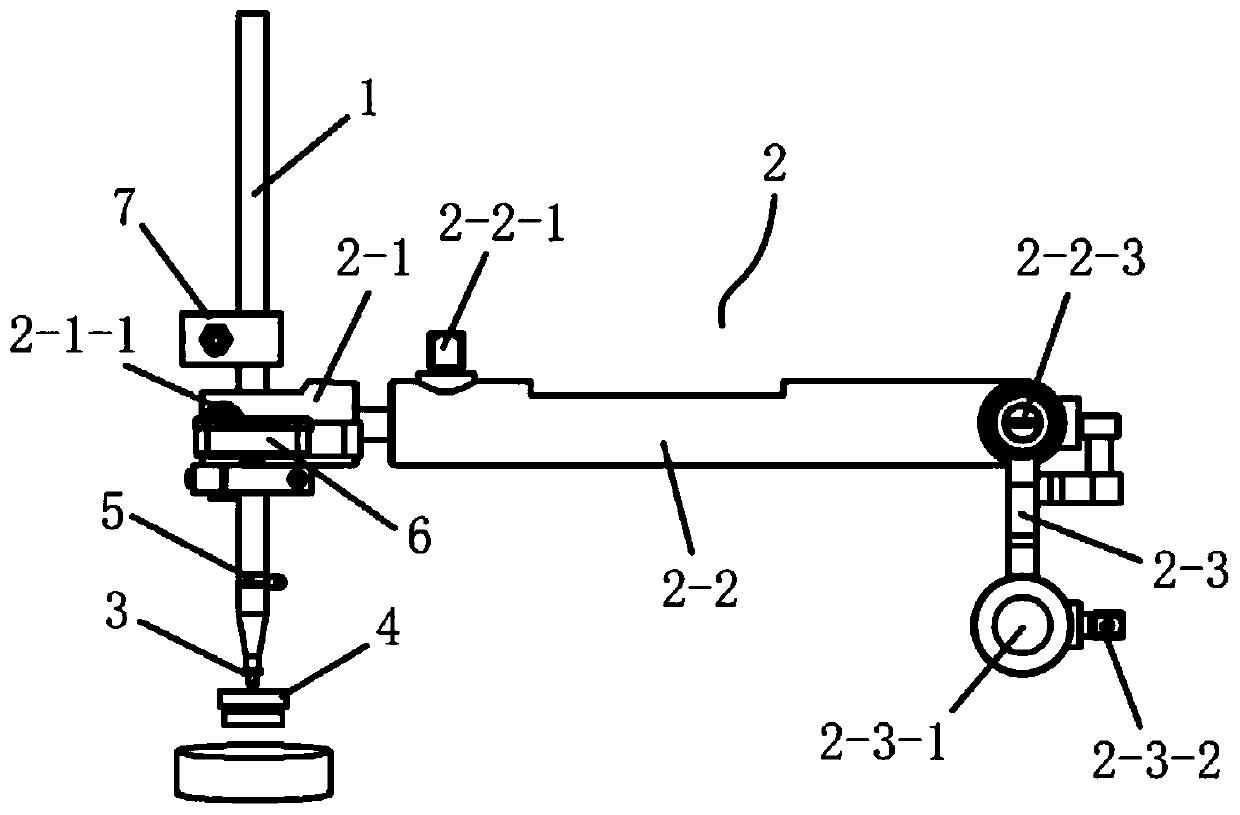

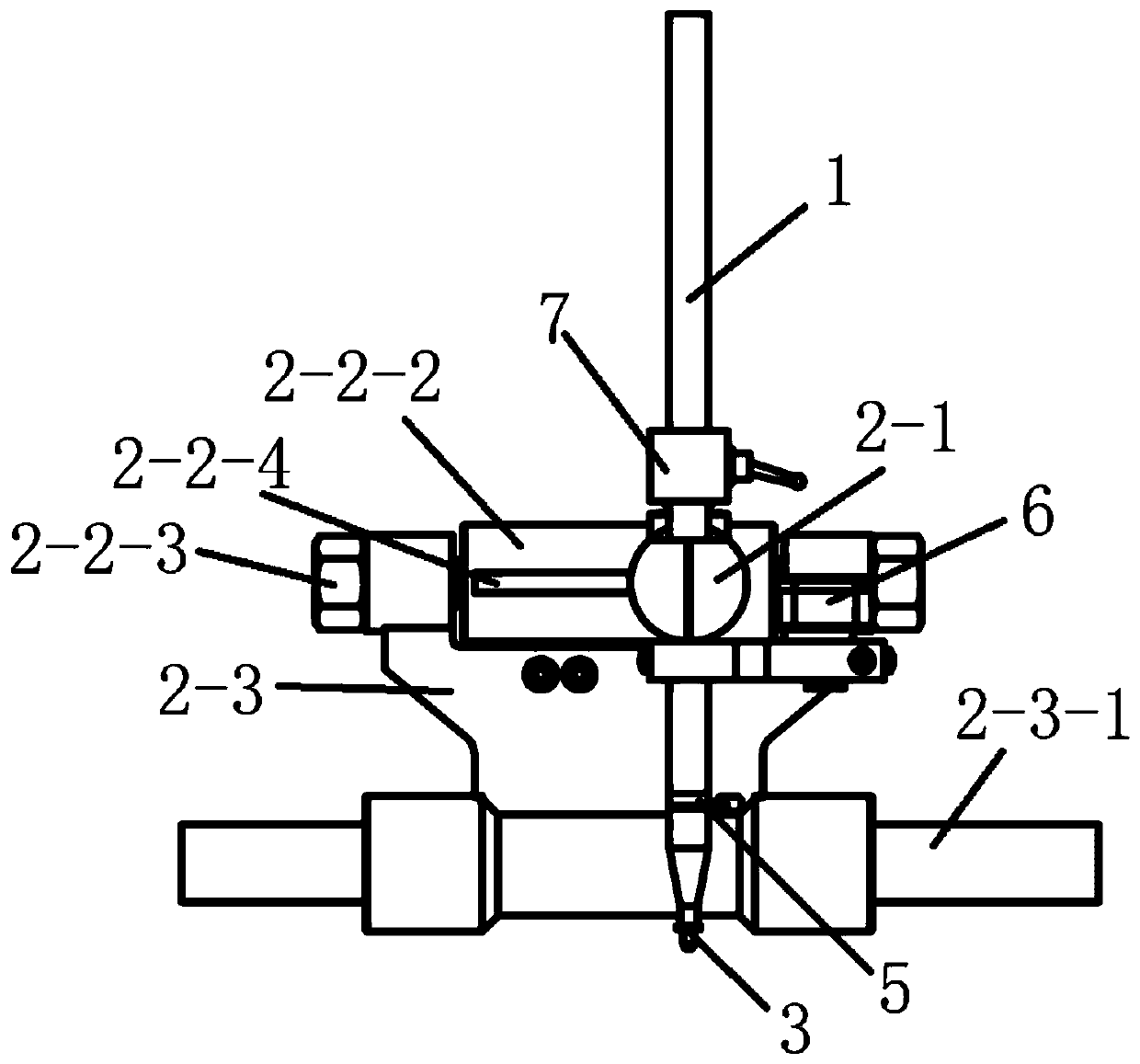

[0025] Such as Figure 1-Figure 4 As shown, the present invention provides a real-time monitoring device for convex grinding frequency of a piezoelectric quartz wafer, comprising a thimble 1 connected to a drive mechanism 2, the lower part of the thimble 1 has a needle 3, and the needle 3 abuts against On the metal tool tray 4 for carrying the wafer to be processed, and the needle 3 is connected to the signal input end of the test electrode wire 5, and the test electrode wire 5 is wound on the thimble 1 above the needle 3 , the signal output end of the test electrode line 5 is connected to the frequency measuring instrument 6, and the frequency measuring instrument 6 is connected to the grinding controller.

[0026] In this embodiment, the frequency signal is applied to resonate with the inherent piezoelectric frequency of the wafer, and the piezoelectric frequency of the wafer is resonated, monitored in real time through the needle, and the monitoring signal is transmitted to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com