High-efficiency low-carbon energy-saving heating ring

A heating ring and high-efficiency technology, applied in the direction of the shape of the heating element, can solve the problems of poor thermal insulation effect of the outer layer, non-compliance with low-carbon environmental protection, and high workshop temperature, so as to improve the heat transfer efficiency, avoid the entry of external dust, and maintain Time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

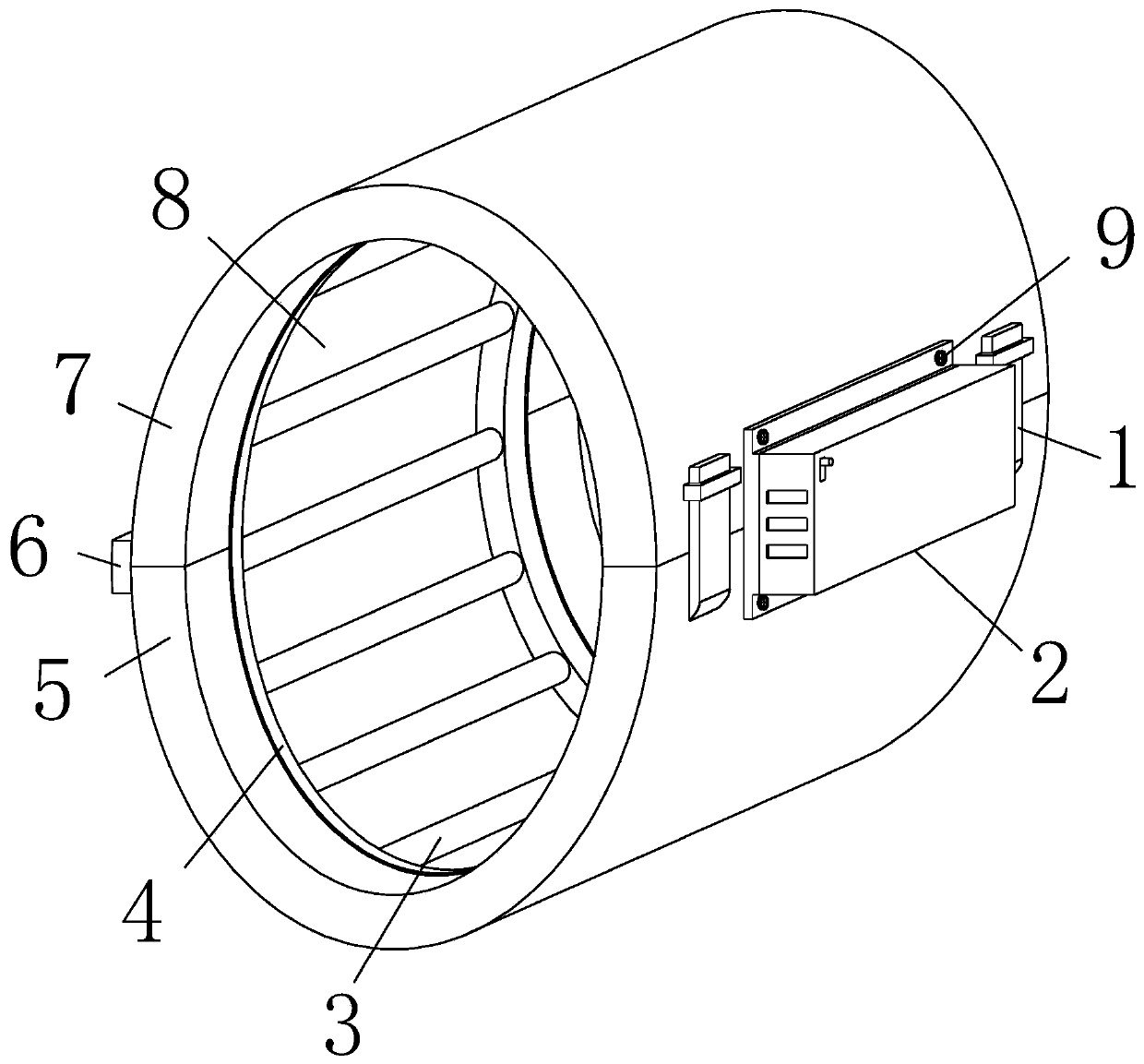

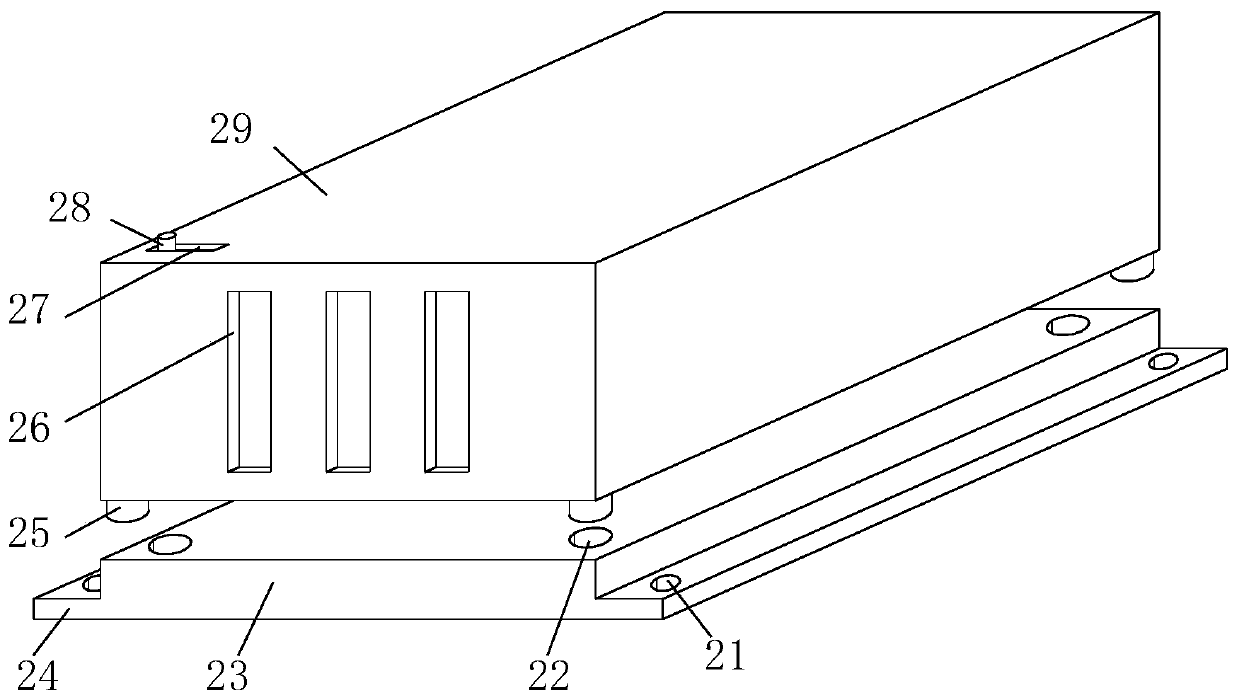

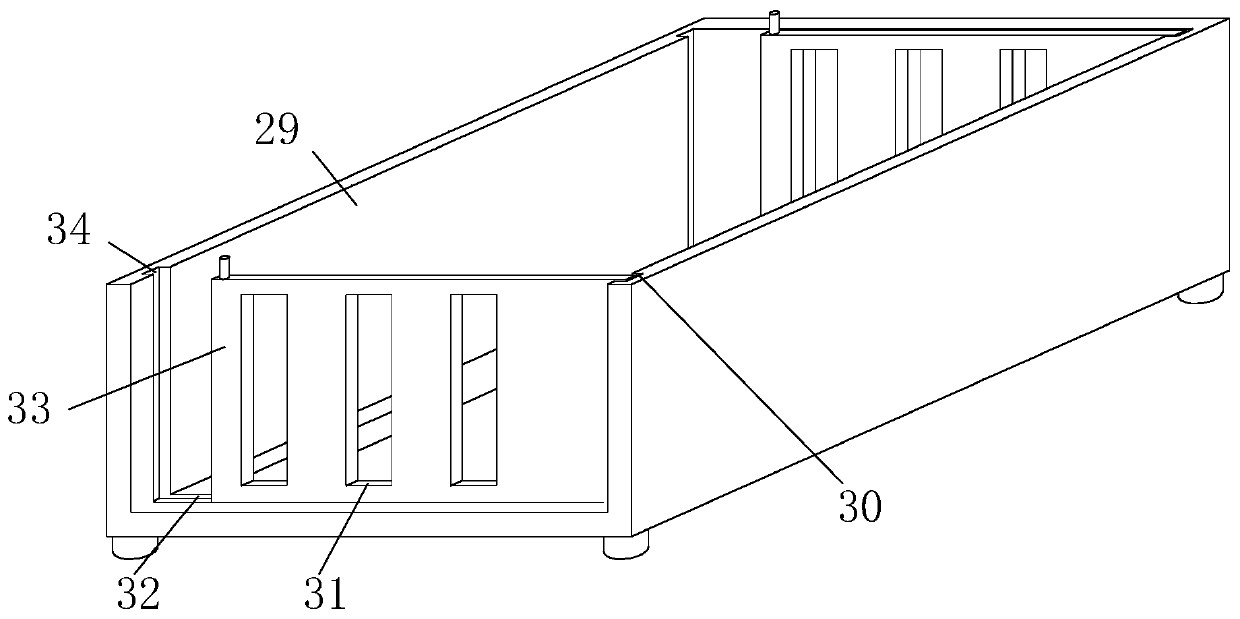

[0027] see Figure 1-5 , the present invention provides the following technical solutions: a high-efficiency, low-carbon, energy-saving heating coil, including a first heating coil housing 5, one end of the first heating coil housing 5 is connected to a second heating coil housing 7, the first heating coil housing One side of the body 5 and the second heating coil housing 7 is rotatably connected by a hinge 6, and the other side of the first heating coil housing 5 and the second heating coil housing 7 is engaged and connected by a buckle 1. A heating coil housing 5 and a second heating coil housing 7 are installed on the side close to the buckle 1 and located in the middle of the intersecting control wiring mechanism 2, the control wiring mechanism 2 and the first heating coil housing 5 and the control wiring mechanism 2 and the second heating coil housing 7 are connected through the installation mechanism 9, and two positioning rings 4 are installed inside the first heating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com