Measuring Method of Wheel Axle Side Slip Angle and Cornering Stiffness Based on Fourier Transform

A technology of Fourier transform and cornering stiffness, which is applied in wheel testing, measuring devices, elastic testing, etc., can solve the problems of high cost and difficult configuration of optical sensors, robustness and practicality to be improved, and limited scope of application, etc., to achieve The effect of low measurement cost, not easy to be disturbed by the external environment, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] This measurement method is based on the harmonic response mechanism of the vehicle system, so the test scenarios mainly include the following two types: (1) Under the external harmonic excitation, the general vehicle will show the harmonic response under the forced vibration, such as passenger car Standard serpentine pile test; (2) Under external non-periodic excitation, special vehicles will show harmonic response under free vibration, such as the dynamic critical oscillation test triggered by high-speed articulated vehicles under pulse excitation.

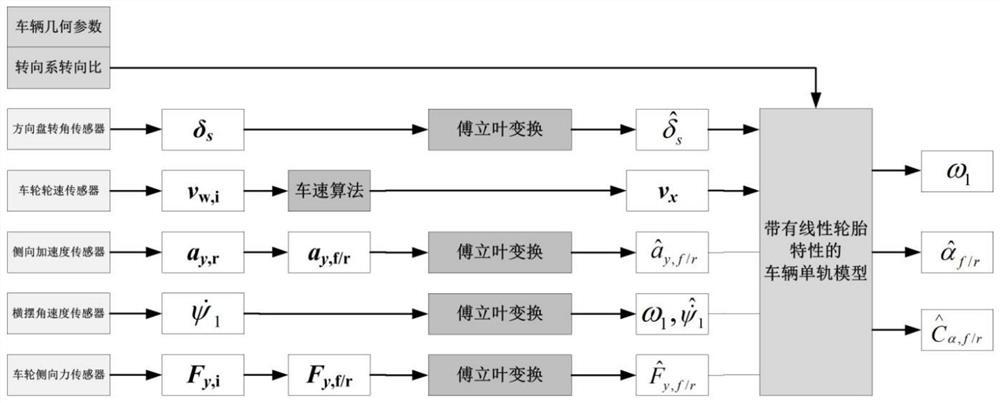

[0027] Such as figure 1 Shown, a kind of measuring method of wheel axle slip angle and cornering stiffness based on Fourier transform of the present invention comprises the following steps:

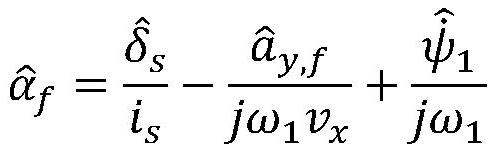

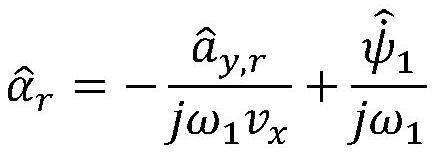

[0028] (1) Calculate the axle slip angle and wheel slip angle, and obtain the wheel speed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com