Manufacturing method of highly integrated electronic frequency divider

A technology of integrated electronics and a manufacturing method, applied in the field of high-integrated electronic frequency divider manufacturing, can solve the problems of low integration of pulse dividers and triggers, large occupied area, large workload, etc. Simple, uniquely conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

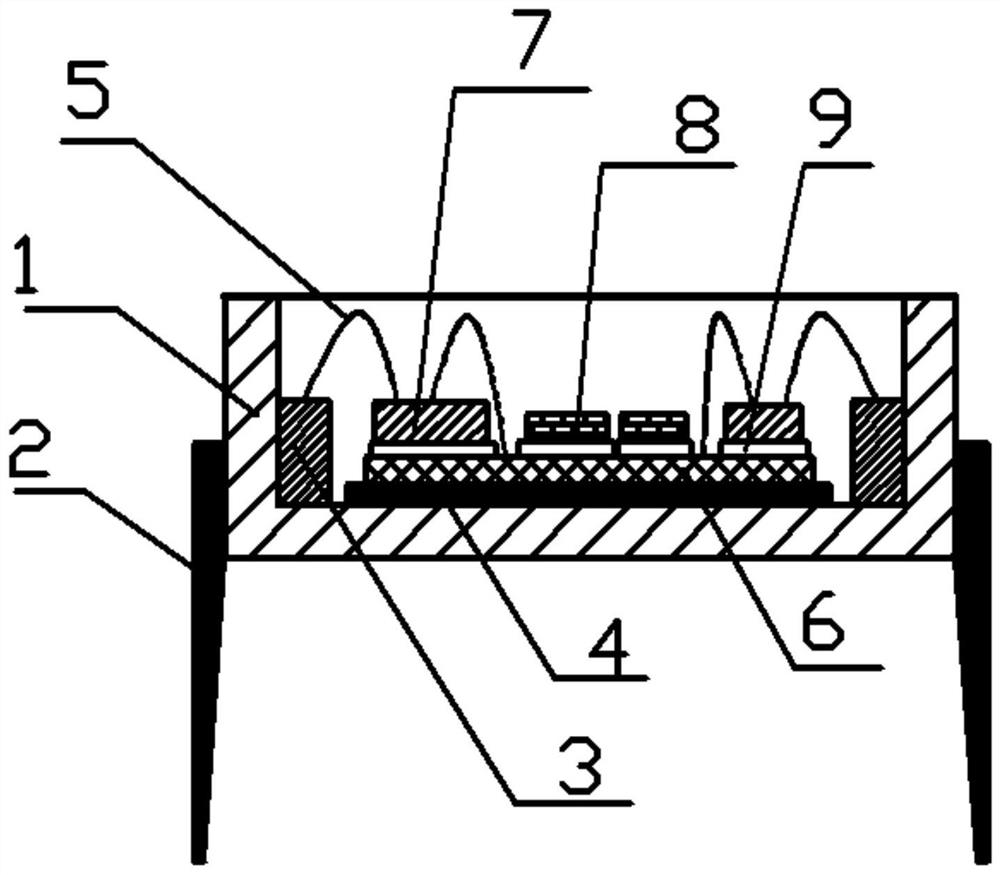

[0055] like Figure 1-5 , the highly integrated electronic frequency divider device comprises an encapsulation shell (1), a ceramic substrate (6) arranged on the encapsulation shell (1) by bonding the substrate film (4), and a ceramic substrate (6) arranged on the ceramic substrate (6) The conductive glue (9), the pulse distributor and the trigger chip (7) distributed on the ceramic substrate (6) through the conductive glue (9) and electrically connected to the power supply to be aged (8), are arranged in the package shell (1). ) in the case inner electrode (3), the case lead (2) arranged on the package case (1) and electrically connected to the case inner electrode (3), and the gold wire (5);

[0056] The gold wire (5) is used to electrically connect the pulse distributor and the trigger chip (7), the power supply to be aged (8), and the inner electrode (3) of the casing;

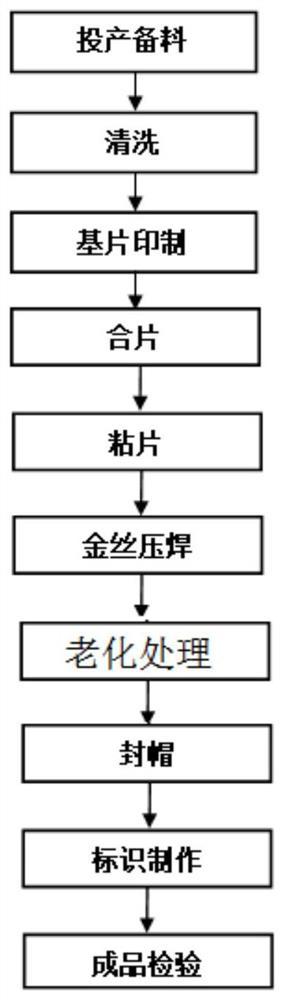

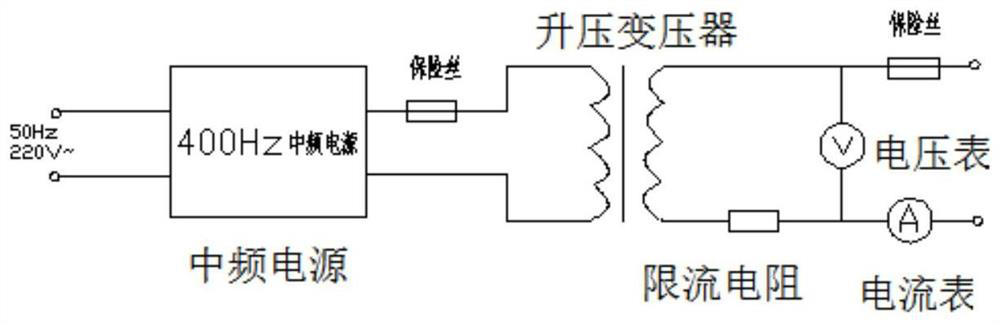

[0057] A method of making a highly integrated electronic frequency divider device; comprising the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com