Machining process numerical control code standardized integration model and method

A technology of numerical control code and mechanical processing, which is applied in the direction of program control, computer control, simulator, etc., can solve the problems of non-uniform numerical control code writing and high requirements for numerical control coding technicians, so as to improve programming efficiency, reduce technical requirements and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

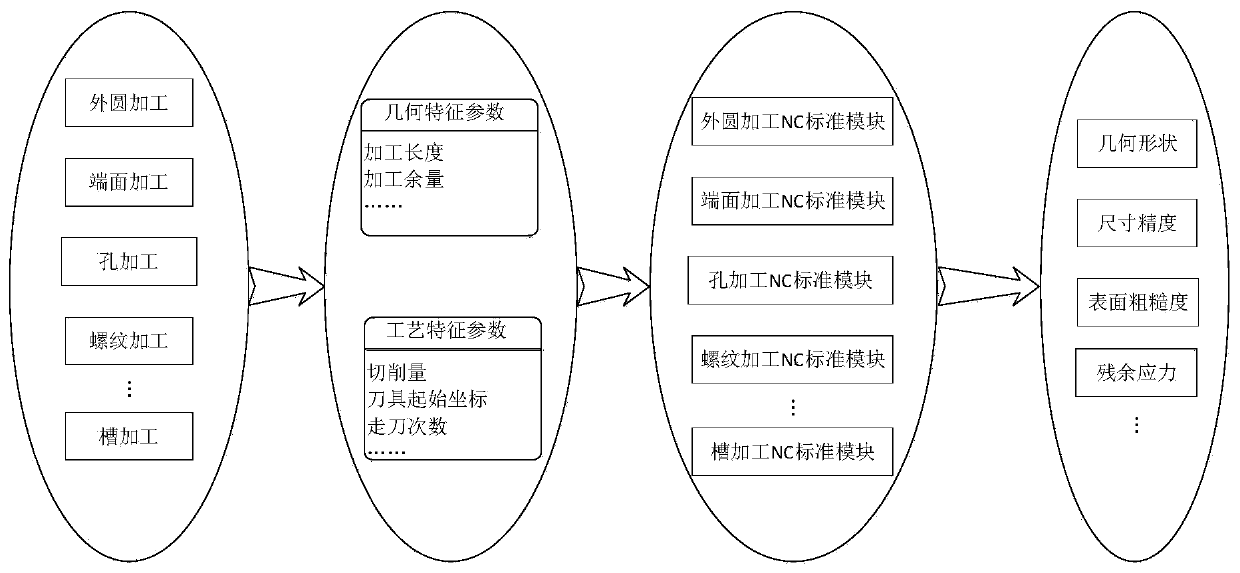

[0034] Embodiment 1. CNC code standardization integration model in machining process

[0035] The following describes the process of establishing the CNC code module of the cylindrical turning process as an example. The CNC machine tool is a horizontal lathe, and the CNC system of the machine tool is the Frank system:

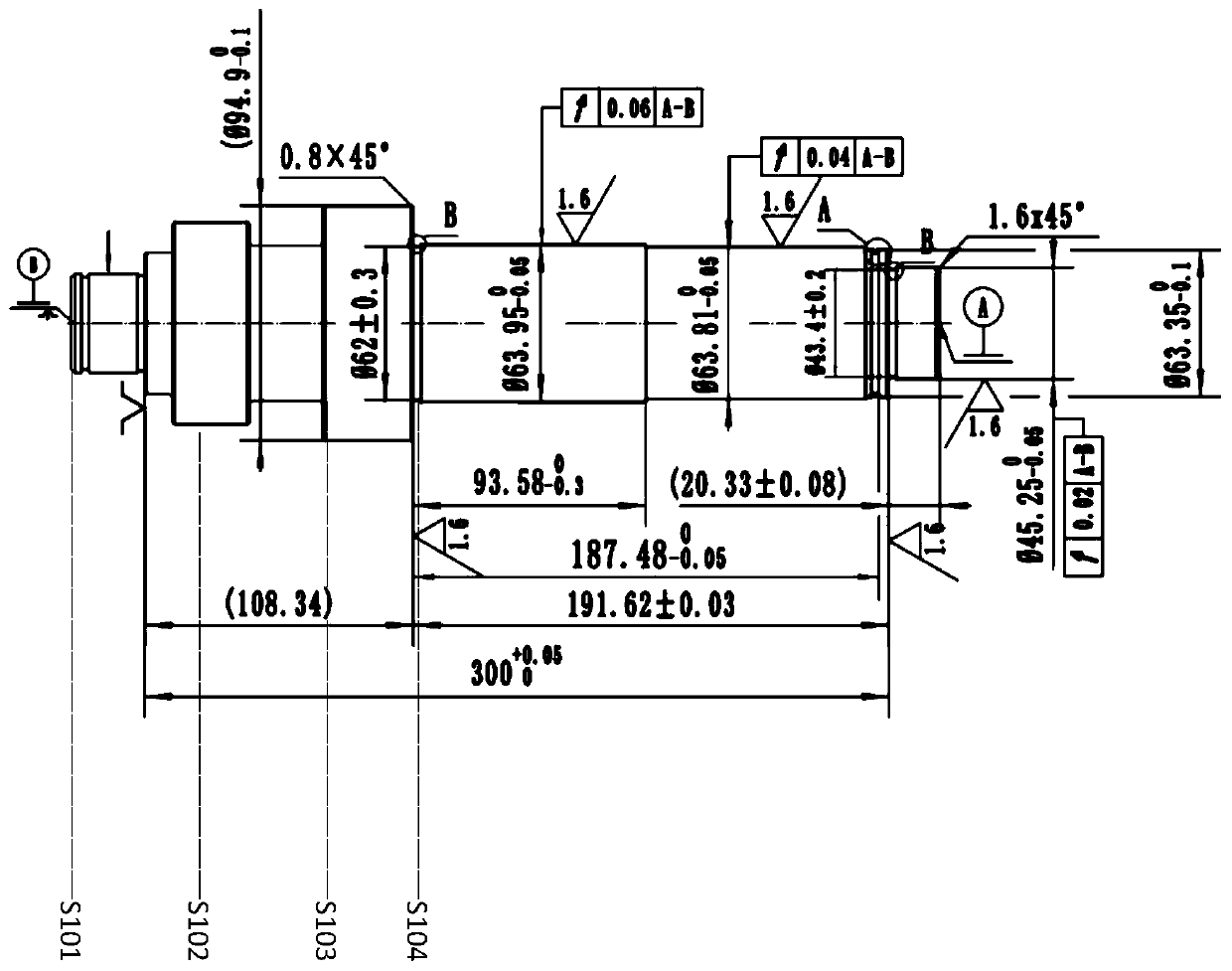

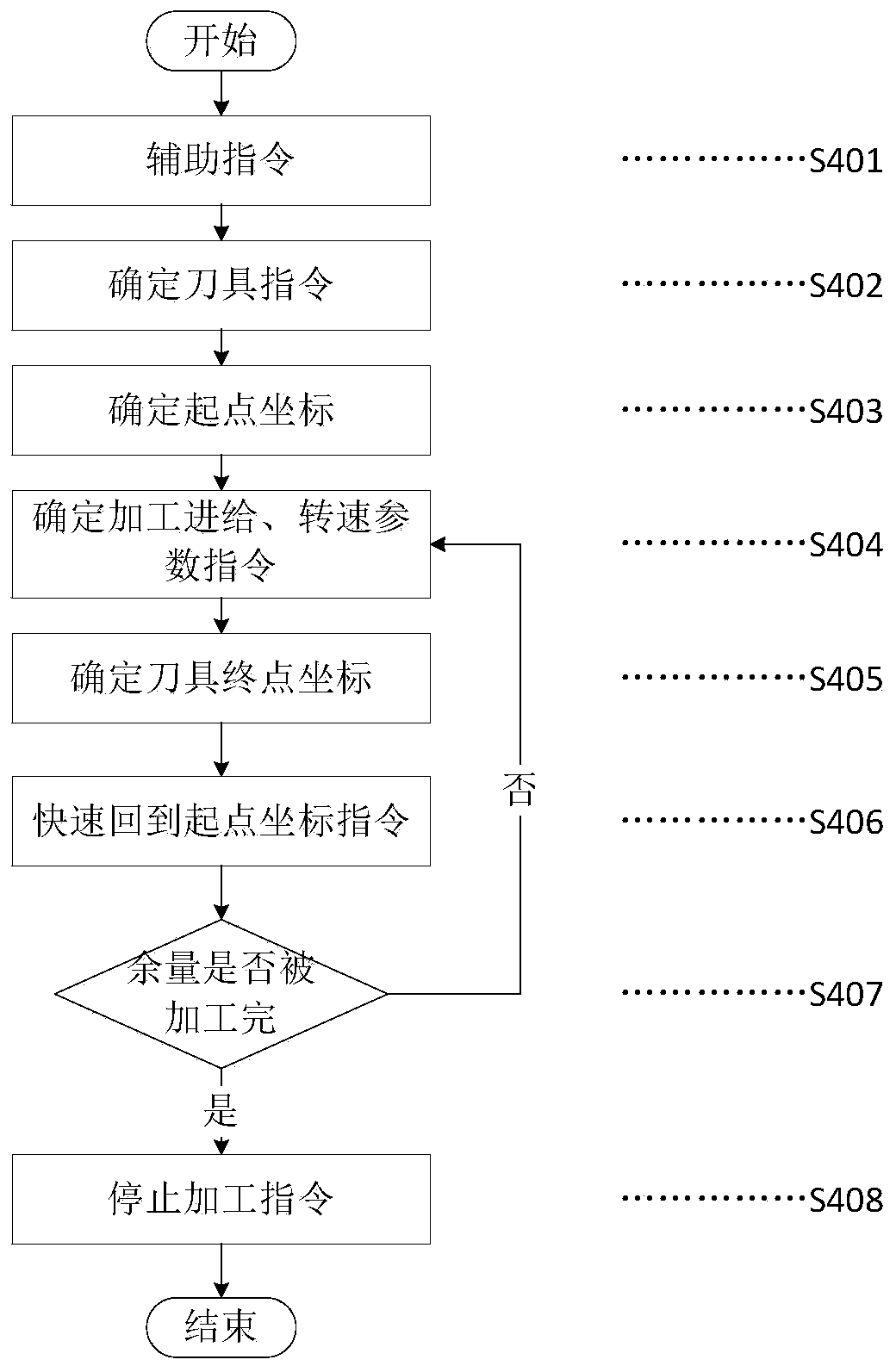

[0036] Such as Figure 4 As shown in the figure, during the turning process of the outer circle, the movement track of the tool tip of the outer circle tool is a straight line parallel to the workpiece axis, as long as the tool cut-in coordinates, the tool cut-out coordinates, the machining allowance on one side of the part and the cutting depth of each tool are determined The change value set of the tool tip's motion track coordinates in the process of external turning can be obtained.

[0037] In the process of external turning, in order to ensure the surface quality of the final workpiece, specific processing parameters are generally set for the last pass, ...

Embodiment 2

[0062] Embodiment 2. Standardized integration method of numerical control code in machining process

[0063] The method provided in this embodiment is: modularize the numerical control codes of each process of numerical control machining and store them in the enterprise database or other shared databases, and the operator selects the numerical control modules according to the process characteristics of the processed parts, and finally concentrates them into complete CNC machining of the parts. Code framework, the operator then sets the necessary tool starting coordinates according to the machine tool CNC system, machine tool coordinate system and part drawing size information, and then the complete CNC machining code file of the part can be determined, and finally the operator imports the code into the CNC equipment for generation processing.

[0064] Such as figure 1 As shown, the parts include S101 chamfering processing, S102 outer circle processing, S103 end face processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com