Liquid injection equipment and liquid injection method of battery cell

A battery cell and liquid injection technology, applied in circuits, electrical components, battery pack components, etc., can solve the problems of low production efficiency, low degree of automation, and unguaranteed product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

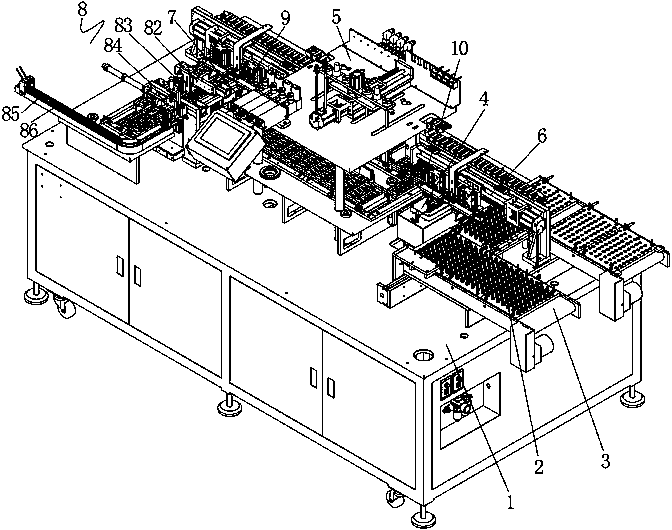

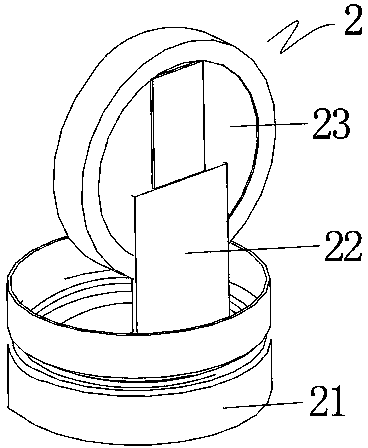

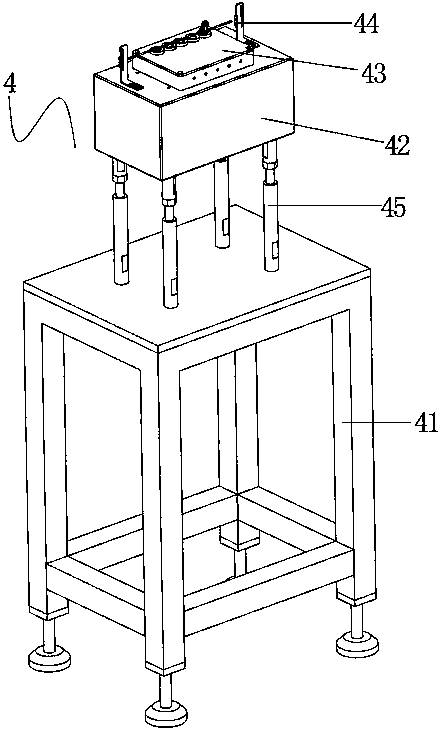

[0031] Reference attached Figure 1~7 , a kind of liquid injection equipment of electric core, comprises frame 1, and frame 1 is provided with the feeding belt 3 that is used for electric core 2 feeding, the weighing mechanism-4 that is used for electric core 2 weighing and injection pump The vacuum mechanism 5 and the weighing mechanism 14 are arranged between the feeding belt 3 and the liquid injection vacuum mechanism 5, and the side of the weighing mechanism 14 is provided with a transport module 6, and the transport module 6 transports the battery cells from the feeding belt 3 is transported to the weighing mechanism 1 4, and the transport module 6 also transports the batteries on the weighing mechanism 1 4 to the liquid injection vacuum mechanism 5; the side of the liquid injection vacuum mechanism 5 is equipped with a wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com