High-efficiency energy-saving switched reluctance motor and preparation method thereof

A switched reluctance motor, high-efficiency and energy-saving technology, used in the manufacture of motor generators, synchronous motors for single-phase current, electrical components, etc., can solve the problems of low conversion efficiency, large vibration and high noise of switched reluctance motors , to achieve high conversion efficiency, improved potential waveform, and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

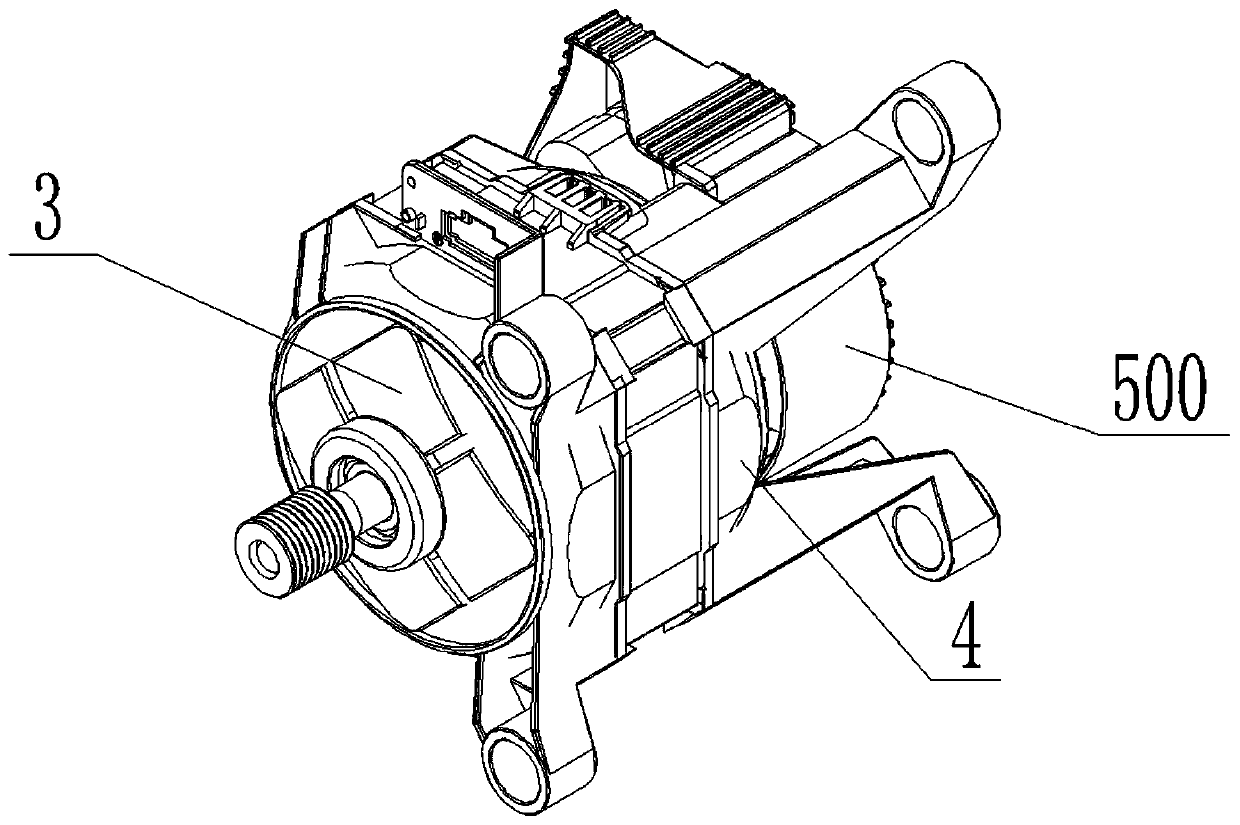

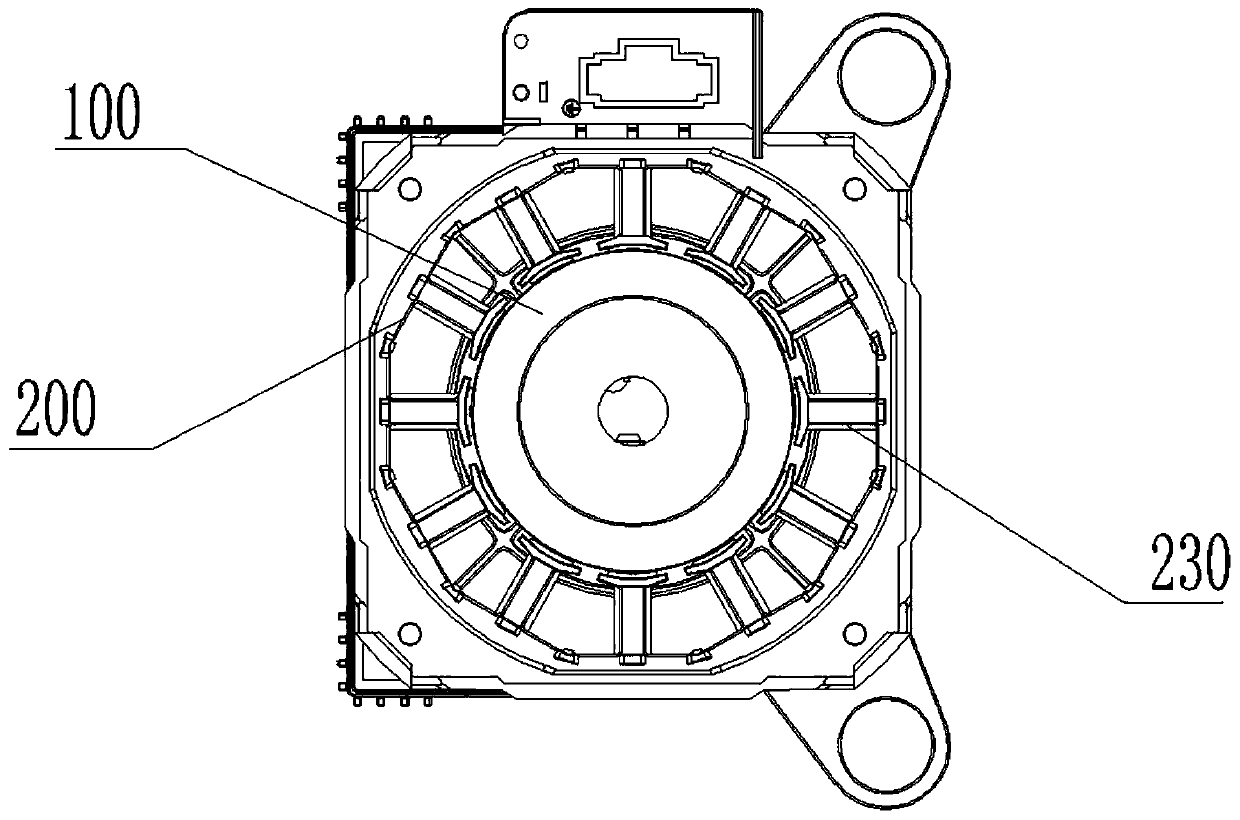

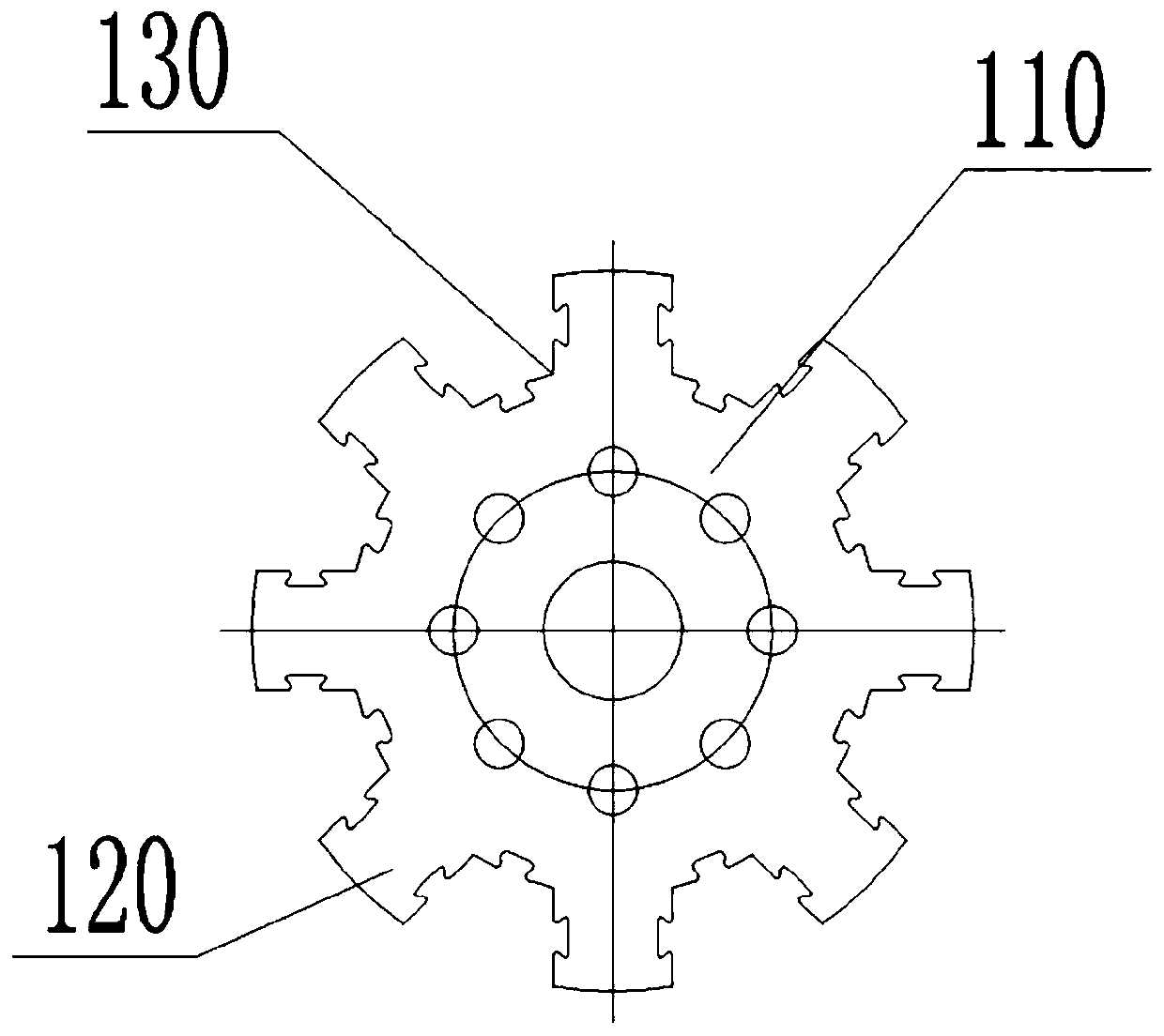

[0028] Example: such as Figure 1 to Figure 4 and Figure 8 , Figure 9 As shown, a high-efficiency energy-saving switched reluctance motor includes a stator 200 and a rotor 100. The stator 200 includes a stator core 230 and a winding 220. The winding 220 is composed of a number of coils distributed in a ring to form a fractional slot concentrated winding structure. The coil is mounted on the stator core 230, the rotor 100 includes a rotating shaft 150 and a rotor core 110, the rotor core 110 is mounted on the rotating shaft 150, and the rotor core 110 is provided with several rotor teeth 120, Dovetail grooves 130 are provided between the adjacent rotor teeth.

[0029] Combined stator core centralized winding technology improves the utilization rate of silicon steel sheets by more than 20%, which significantly reduces the cost of motor core materials; 120 rotor teeth are designed with dovetail grooves 130 to facilitate plastic sealing of the shape and increase connection str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com