Soft capsule machine

A capsule machine, gelatin technology, applied in the directions of capsule delivery, food science, drug delivery, etc., can solve the problem of low rotation speed of the main mold shaft, and achieve the effects of improving the degree of automation, improving labor efficiency, and easy and quick adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

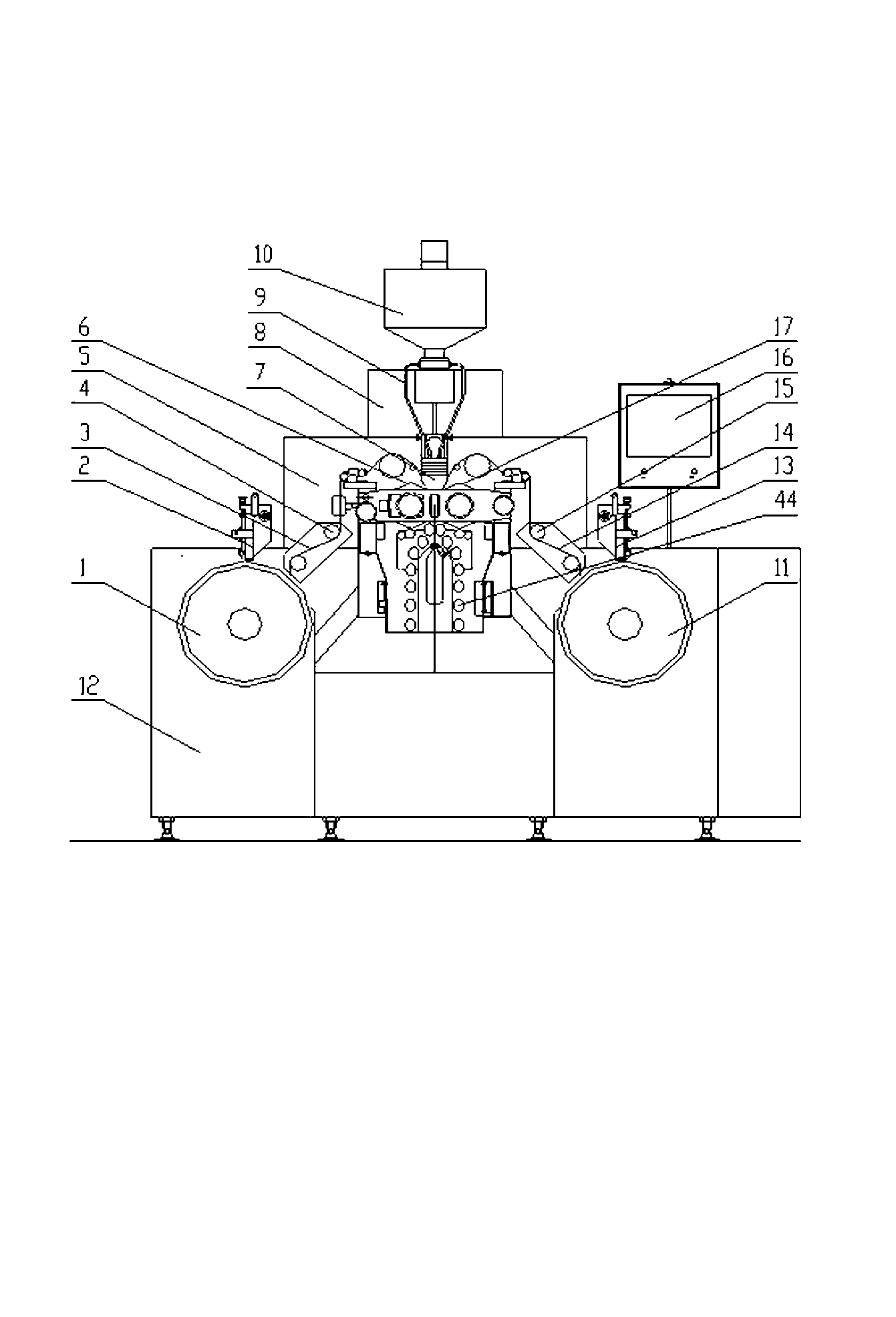

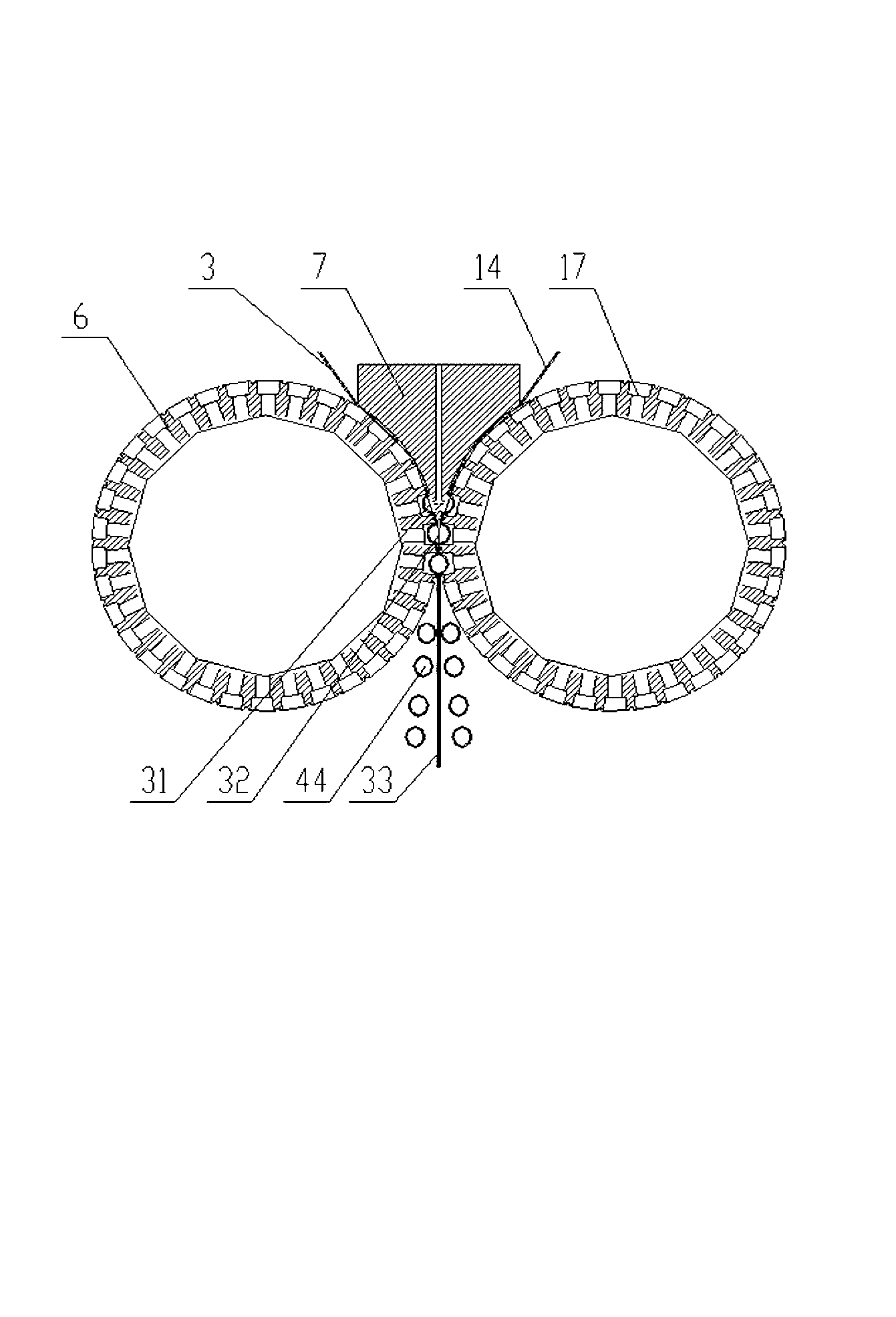

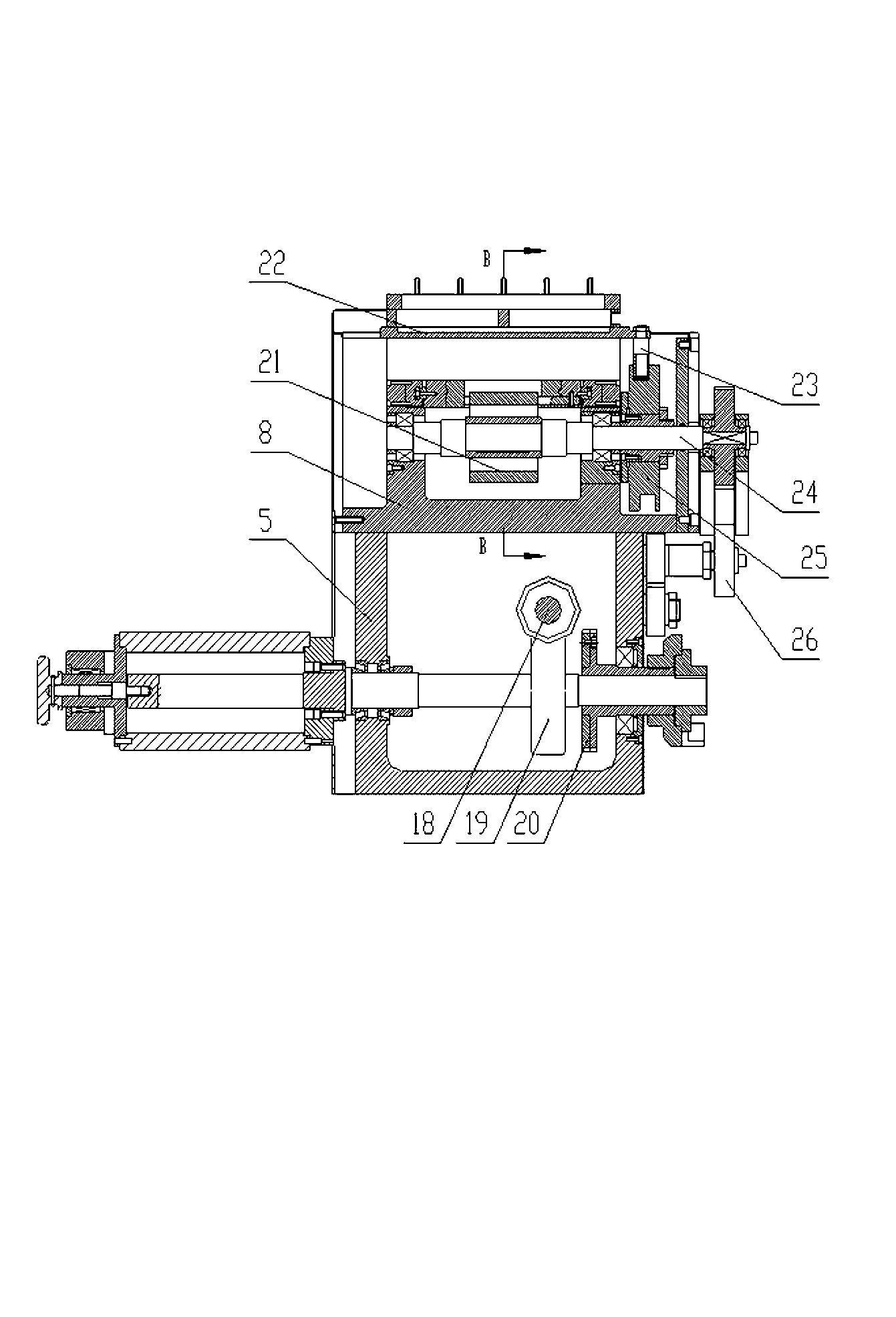

[0030] Combine below figure 1 , Image 6 , Figure 7 , Figure 8The technical solution of the present invention is described in detail to further understand the purpose, scheme and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

[0031] The overall structure of the soft capsule machine of the present embodiment is the same as that of the prior art soft capsule machine, see figure 1 , the soft capsule machine of the present invention comprises body 12, left gelatin roller 1, left gelatin box 2, left pull rubber roller 4, machine head 5, left mold 6, spray body 7, feed pump 8, feed hopper 10, right gelatin Roller 11, right gelatin box 13, right pull rubber roller 15, touch screen 16 and PLC electrical control system, the difference is that the soft capsule machine head and feed pump of the present invention have been significantly improved relative to the prior art, and the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com