Adaptive Ultrasonic Motor Based on Temperature Tracking

An ultrasonic motor, self-adaptive technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of narrowing the working speed range, and achieve a compact design structure , increase stability, wide field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

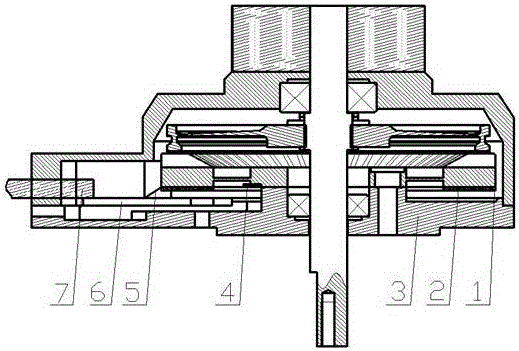

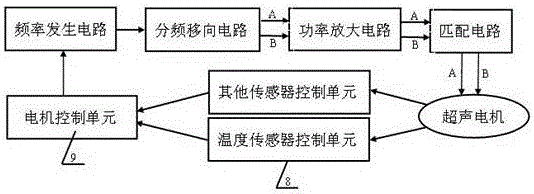

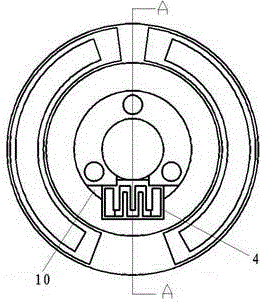

[0054] The self-adaptive ultrasonic motor based on temperature tracking of the present invention is based on the existing ultrasonic motor technology. The motor stator is composed of stator metal parts 1, piezoelectric ceramics 2, and flexible printed circuit board 5. Electrode glue bonding, special positioning tooling is used in the bonding process; the rotor is composed of rotor metal parts and friction materials, which are bonded together by medium temperature electrode glue, and special positioning tooling is also required.

[0055] The assembly relationship of the various parts of the motor is as follows: the stator and the base are connected with M2.5*8 flat head screws; the motor shaft and the rotor are connected through gears; the rotor is installed above the stator, between the shaft shoulder and the inner ring of the support bearing on the casing Increase the adjustment washer to apply the preload between the stator and the rotor; the casing and the base are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com