Full-automatic semiconductor wafer glue spraying equipment

A semiconductor, fully automatic technology, applied in the direction of spraying devices, etc., can solve the problems of conveyor belt transmission obstruction, inconvenient gluing, small size of semiconductor wafers, etc., and achieve the effect of ensuring normal transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

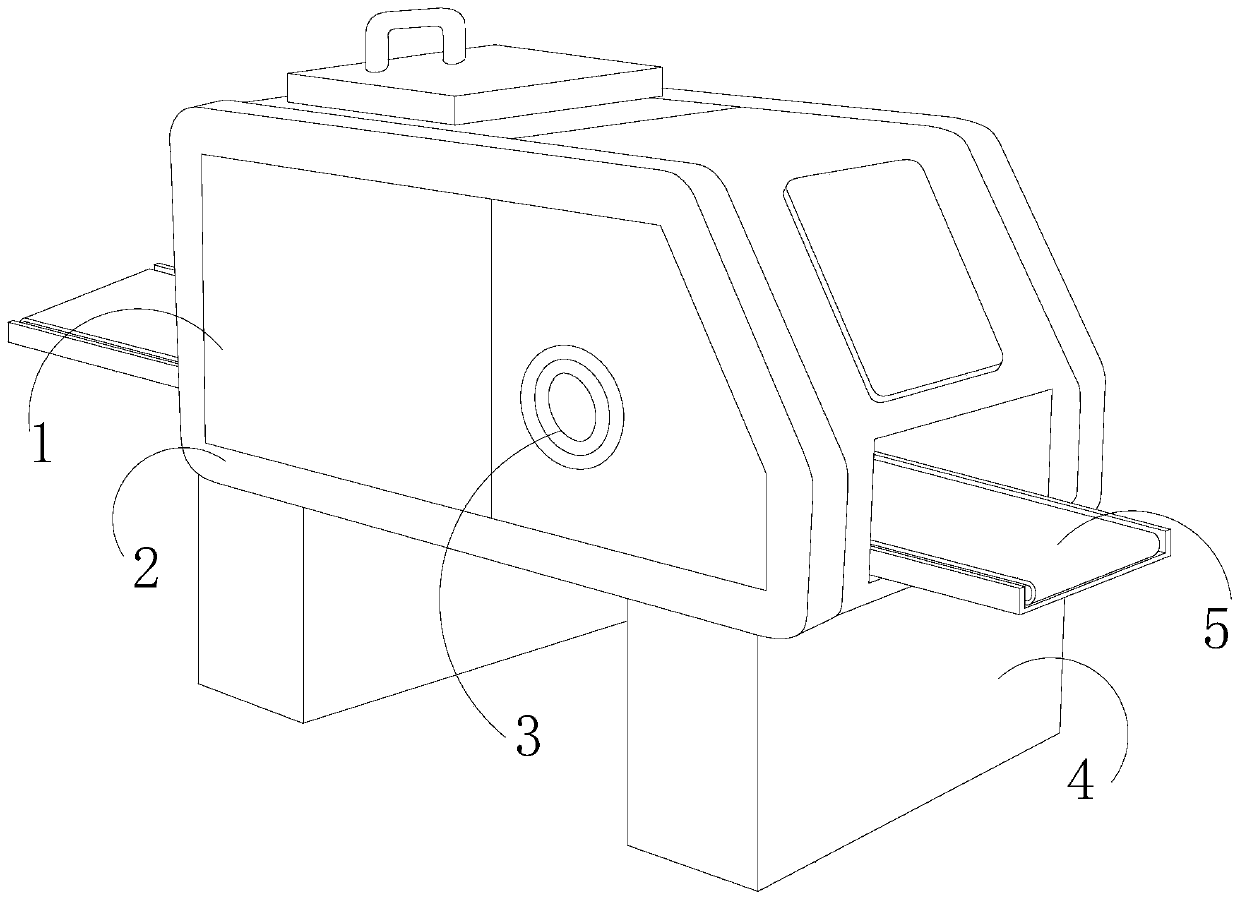

[0027] see Figure 1-Figure 8 , the present invention provides a fully automatic semiconductor wafer glue spraying equipment, the structure of which includes a housing 1, a spacer 2, a vent 3, a support column 4, and a conveyor belt 5, the housing 1 is provided with a spacer 2, the The spacer 2 cooperates with the conveyor belt 5, the conveyor belt 5 passes through the shell 1, the support column 4 is fixedly connected with the shell 1, the vent 3 is arranged on the side of the shell 1, and the vent 3 runs through the shell Body 1;

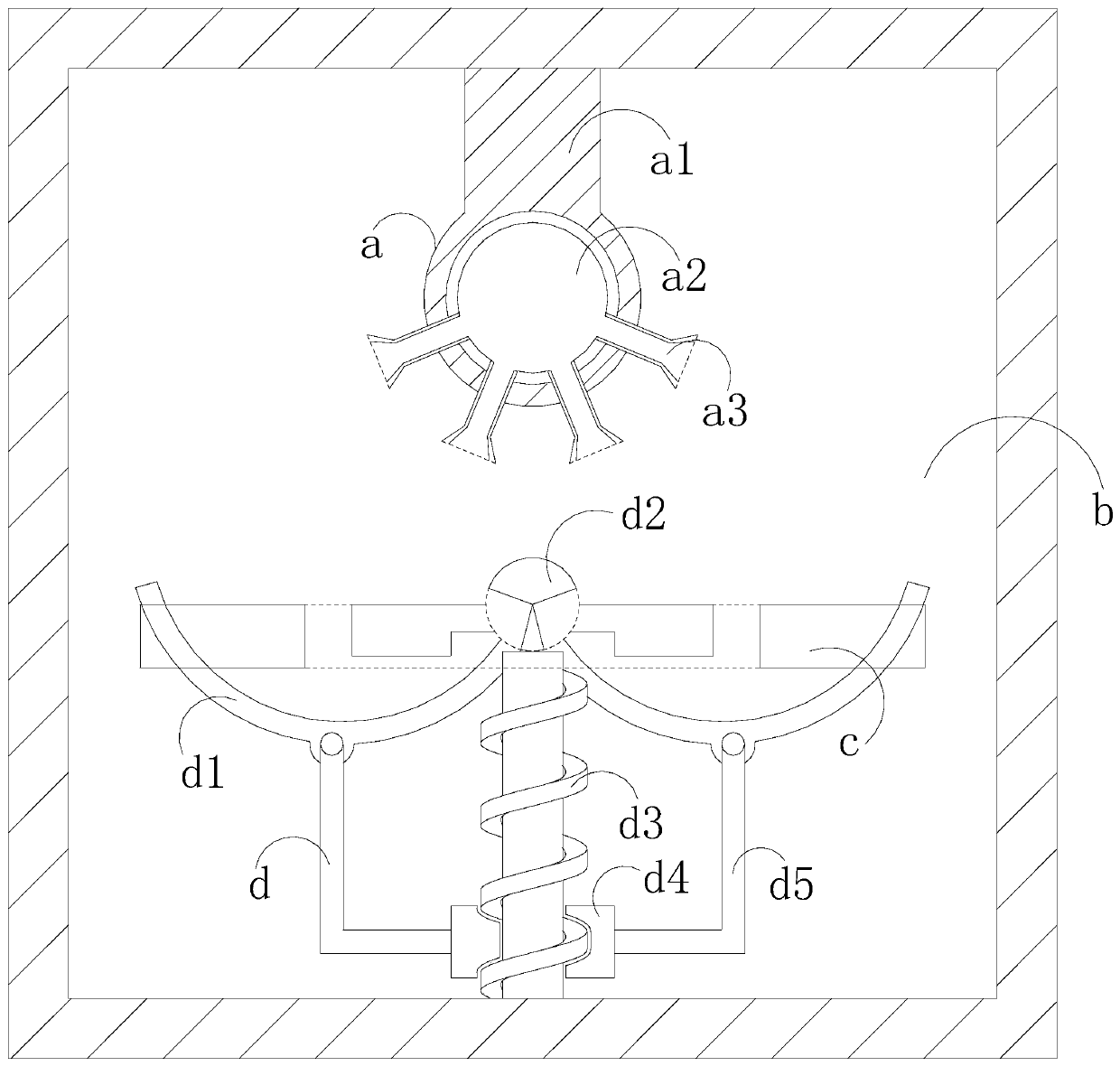

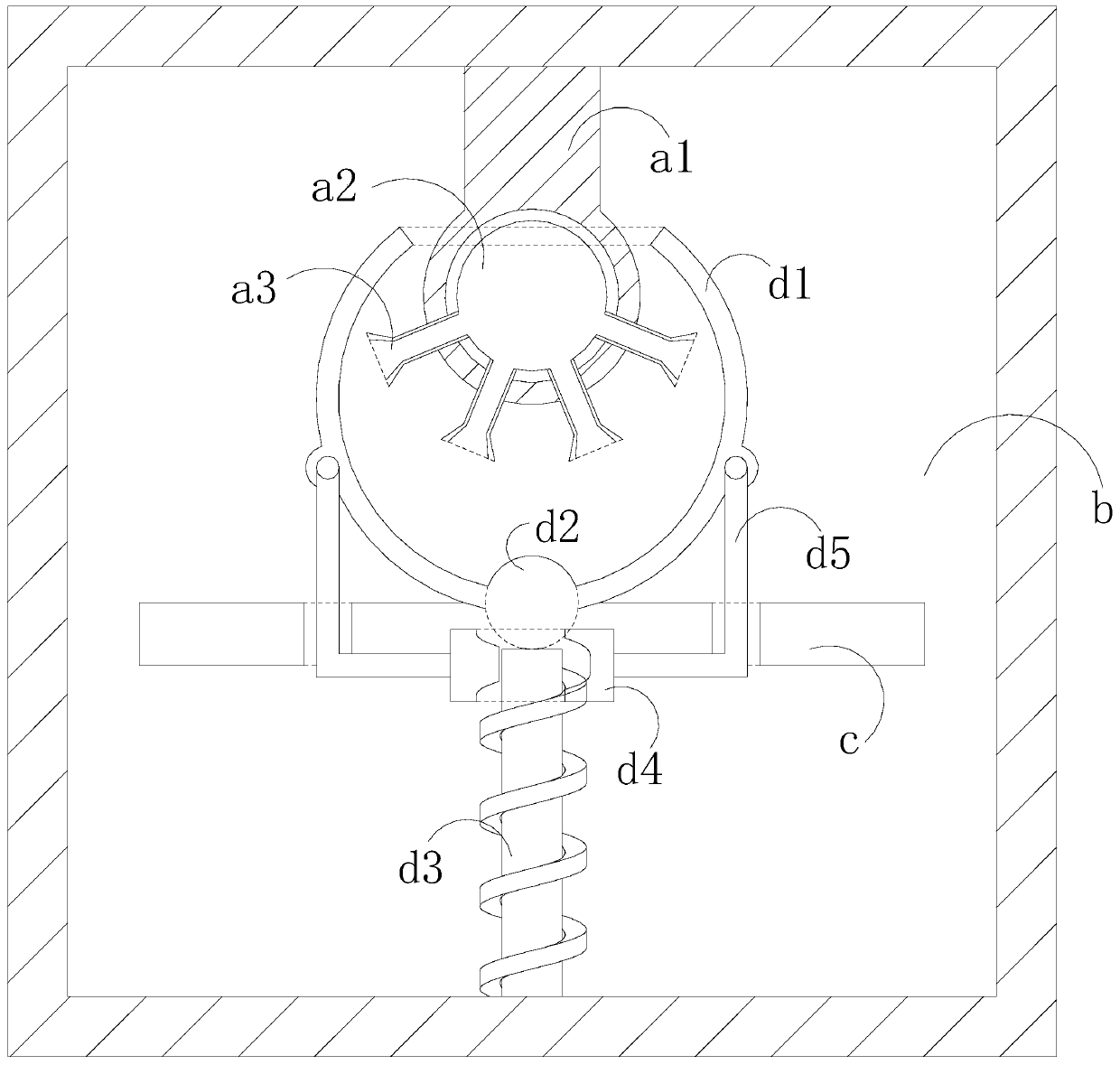

[0028] The spacer 2 is composed of a glue spray head a, a working chamber b, a processing table c, and an anti-splash mechanism d. The glue spray head a is installed in the working chamber b, and the glue spray head a is arranged on the top of the working chamber b On the inner wall, the glue spraying head a cooperates with the anti-splash mechanism d, and the anti-splash mechanism d is installed on the processing table c, and the processing tabl...

Embodiment 2

[0036] see figure 1 , Figure 5-Figure 8 , the present invention provides a fully automatic semiconductor wafer glue spraying equipment, the structure of which includes a housing 1, a spacer 2, a vent 3, a support column 4, and a conveyor belt 5, the housing 1 is provided with a spacer 2, the The spacer 2 cooperates with the conveyor belt 5, the conveyor belt 5 passes through the shell 1, the support column 4 is fixedly connected with the shell 1, the vent 3 is arranged on the side of the shell 1, and the vent 3 runs through the shell body 1; the spacer 2 is composed of a glue spray head a, a working chamber b, a processing table c, and an anti-splash mechanism d. The glue spray head a is installed in the working chamber b, and the glue spray head a is set On the inner wall of the top of the chamber b, the glue spray head a is matched with the splash prevention mechanism d, and the splash prevention mechanism d is installed on the processing table c, and the processing table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com