Method for improving thick plate production efficiency of single-stand rolling mill

A production efficiency, single-stand technology, applied in the field of steel rolling production, can solve the problems of longer idle time of the rolling mill, large deformation resistance, and prolonged temperature drop time, so as to save the cooling time, improve the efficiency of the rolling mill, and increase the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for improving the production efficiency of thick plates in a single-stand rolling mill, the thickness of the finished product is 50-150 mm, comprising the following steps:

[0019] T1. One-time heating and rolling, the heating temperature is 1100-1250°C, and the thickness of the intermediate billet is controlled at 1.5-4.0 times the thickness of the finished product;

[0020] T2. After the primary heating and rolling, the intermediate billet is directly cooled to 100-400°C;

[0021] T3, secondary heating and rolling, the heating temperature is 900-1000 ℃, and the thickness of the finished product is directly rolled after tapping.

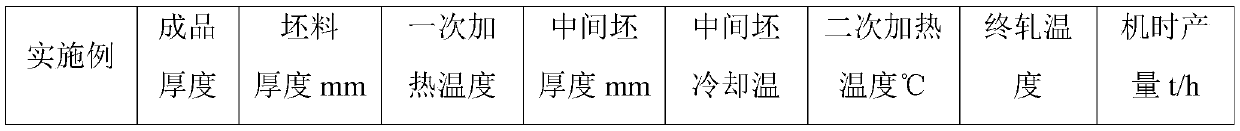

[0022] Table 1 is 3 specific embodiments of the present invention:

[0023]

[0024]

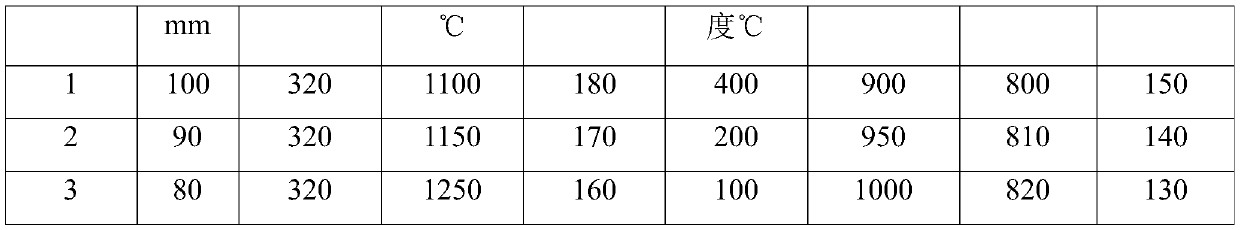

[0025] Compared with the existing production technology, the comparison of process parameters and production efficiency is shown in Table 2:

[0026] Table 2 The present invention and the production technology of prior art and production ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com