Waste steel wire rope or steel strand shot cutting equipment

A steel wire rope and steel strand technology, which is applied in the field of waste steel wire rope or steel strand wire shot cutting equipment, can solve the problems of low efficiency and poor safety, and achieve the effects of good safety, high shot cutting efficiency, and improved operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

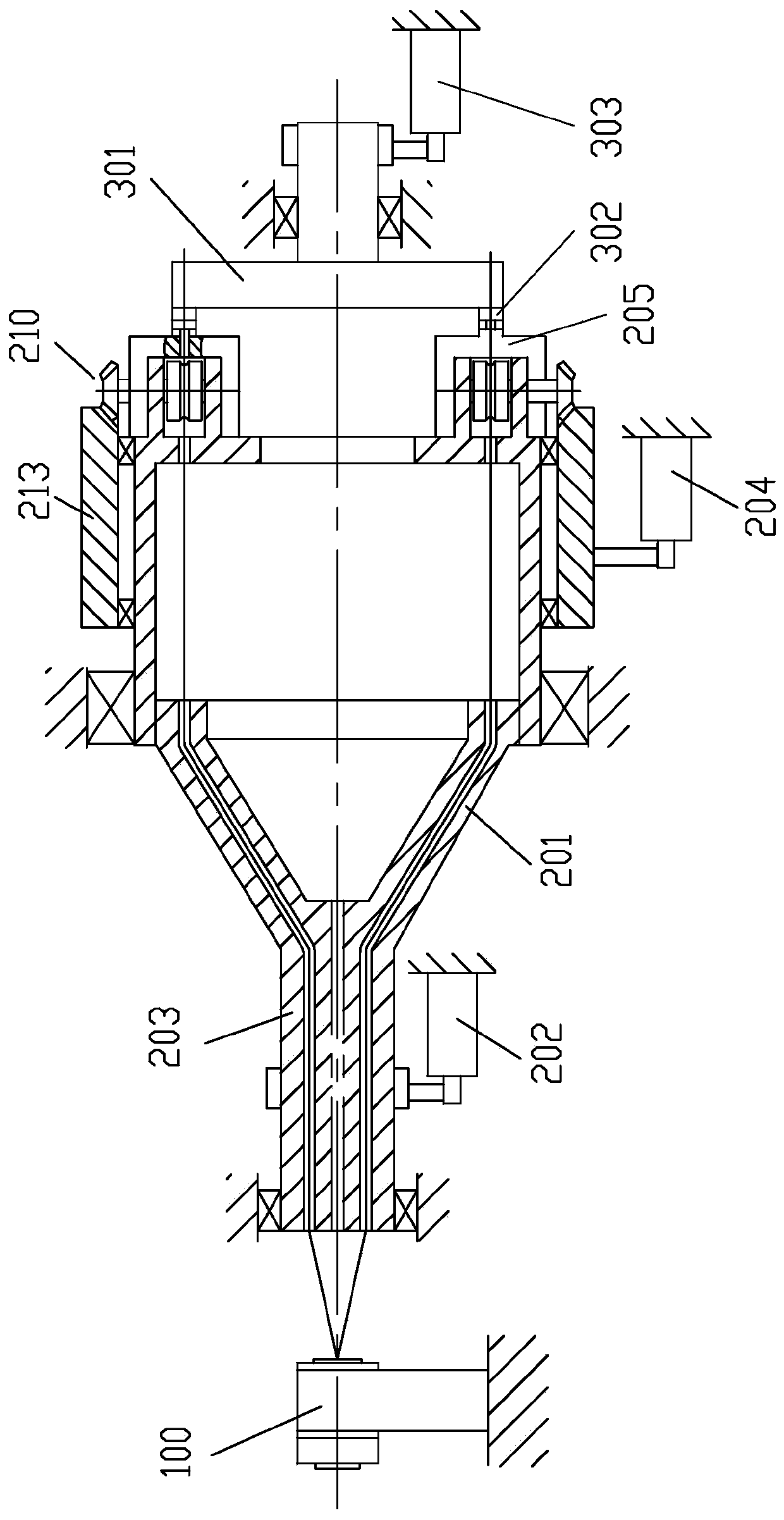

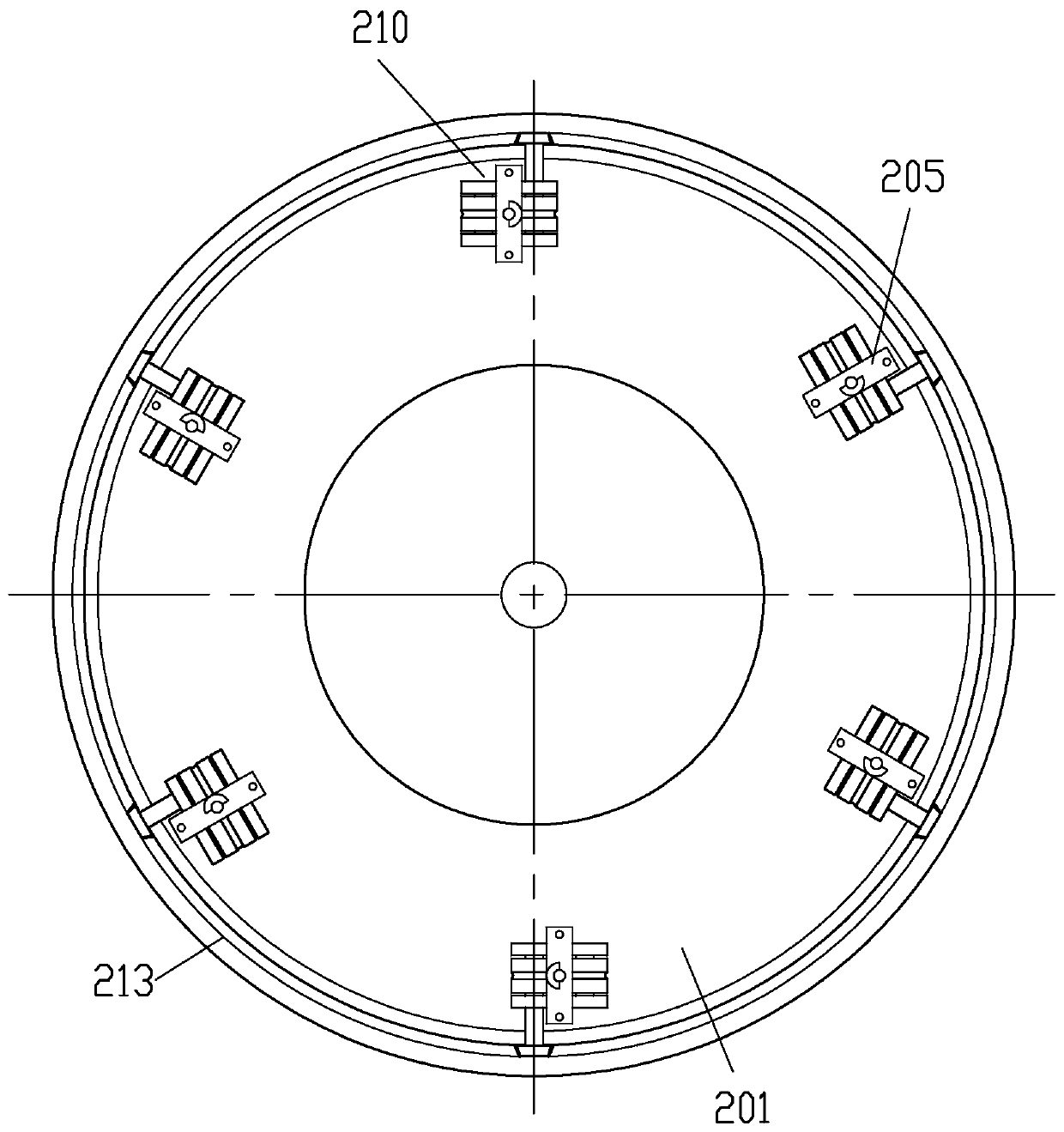

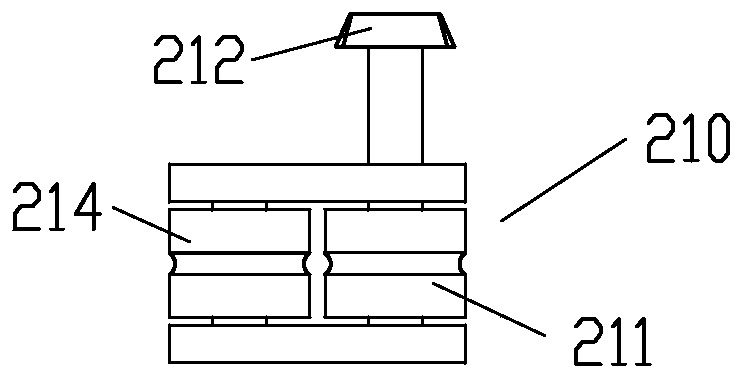

[0031] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 , a kind of waste steel wire rope or steel strand wire shot cutting equipment, including a fixed cutter 205 and a movable cutter 302 with an arc-shaped knife edge, and also includes a first cutting disc 201 for setting the fixed cutter 205, and for setting The second cutter disc 301 of the movable cutter 302; the first cutter disc 201 is circumferentially distributed with a plurality of fixed cutters 205, specifically six fixed cutters 205, and the fixed cutters 205 one by one Corresponding steel wire feeding device 210, the steel wire feeding device 210 pulls the steel wire strand or steel wire through the roller counter-rolling mode; the second cutter disc 301 is rotatably arranged, and the second cutter disc 301 is provided with At least one movable cutter 302 is specifically provided with three movable cutters 302 , and the second cutter disc 301 is connected with a...

Embodiment 2

[0038] Example 2, see Figure 10 , the sun gear is formed by the sun gear 213a, and the sun gear 213a is fixedly connected to the second cutter disc 301 . When passing through the fixed member core wire hoist or core wire winding device, the core wire passes through the center of the first cutter head 201 and the sun gear 213a in sequence

[0039] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0040] Example 3, see Figure 11 The sun gear 213a is rotatably provided on the second cutter disc 301, and the sun gear 213a is connected with the third rotary driving device 204.

[0041] The rest of the structure of this embodiment is the same as that of Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com