A cable pay-off and cutting equipment for municipal engineering

A cutting equipment and engineering technology, used in the field of cable pay-off cutting equipment, can solve the problems of slow cutting speed, easy to bounce, large cable diameter, etc., to achieve the effect of easy to cut the cable, small contact area, and increase the surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

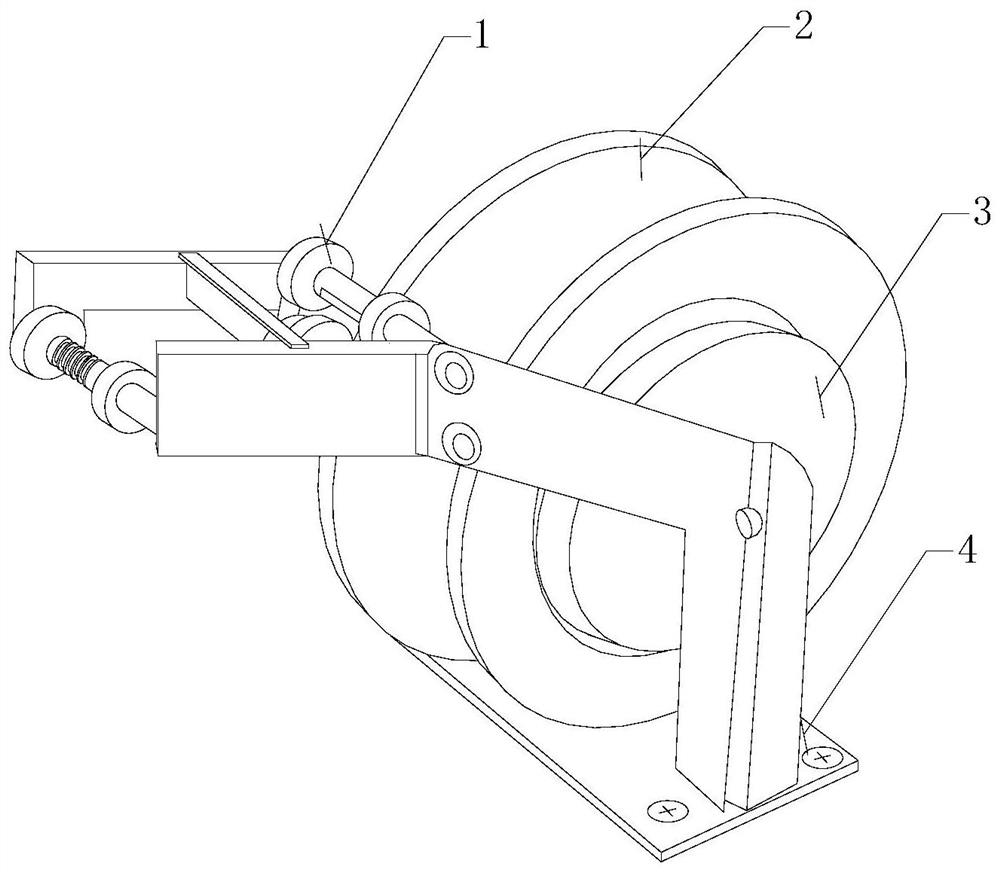

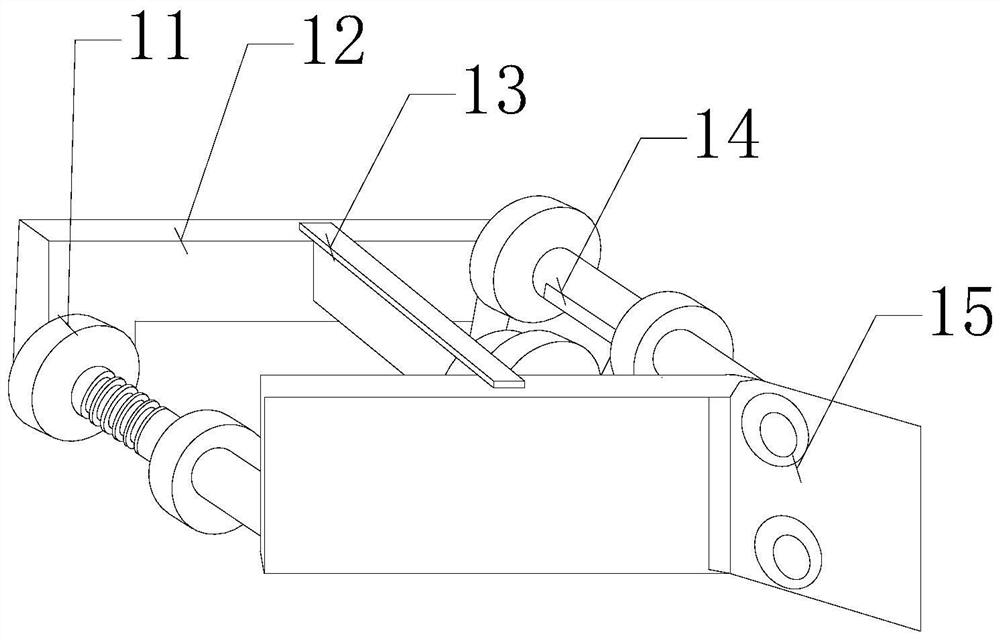

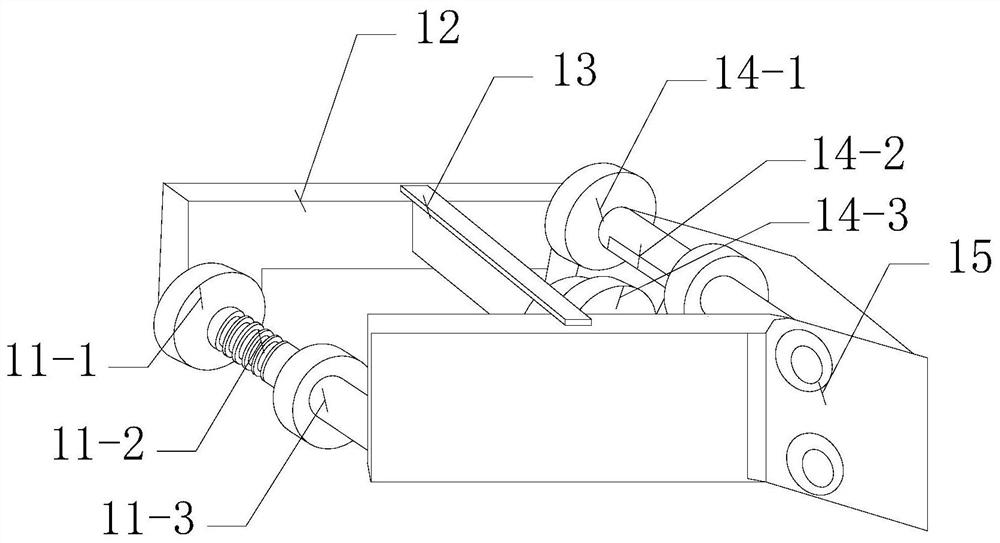

[0026] see Figure 1-Figure 3 , a kind of cable pay-off and cutting equipment for municipal engineering, the present invention provides a kind of cable pay-off and cutting equipment for municipal engineering. The above chassis 4 is provided with winding reel 2, and described winding reel 2 is fixed on the chassis 4 by fixed shaft 3, and the left side of described chassis 4 is equipped with pay-off cutting structure 1, and described pay-off and cutting structure 1 A first fixed frame 11, a first frame plate 12, a press-cut structure 13, a second fixed frame 14, and a second frame plate 15 are provided. The second frame plate 15 and the first frame plate 12 are parallel to each other, and the two are A press-cutting structure 13 is arranged in the middle, and the left and right sides of the press-cutting structure 13 are respectively provided with a first fixing frame 11 and a second fixing frame 14, and the front and rear ends of the first fixing frame 11 and the second fixing ...

Embodiment 2

[0033] see Figure 1-Figure 5, a kind of cable pay-off and cutting equipment for municipal engineering, the present invention provides a kind of cable pay-off and cutting equipment for municipal engineering. The above chassis 4 is provided with winding reel 2, and described winding reel 2 is fixed on the chassis 4 by fixed shaft 3, and the left side of described chassis 4 is equipped with pay-off cutting structure 1, and described pay-off and cutting structure 1 A first fixed frame 11, a first frame plate 12, a press-cut structure 13, a second fixed frame 14, and a second frame plate 15 are provided. The second frame plate 15 and the first frame plate 12 are parallel to each other, and the two are A press-cutting structure 13 is arranged in the middle, and the left and right sides of the press-cutting structure 13 are respectively provided with a first fixing frame 11 and a second fixing frame 14, and the front and rear ends of the first fixing frame 11 and the second fixing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com