Weld joint track monitoring system

A monitoring system and trajectory technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as the decline of mechanical properties of welds, affecting the final quality of components and products, and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

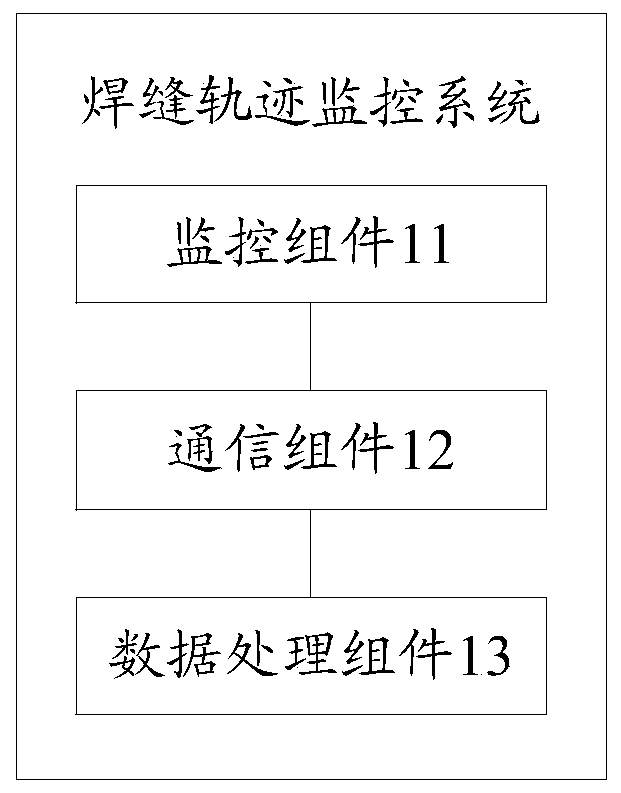

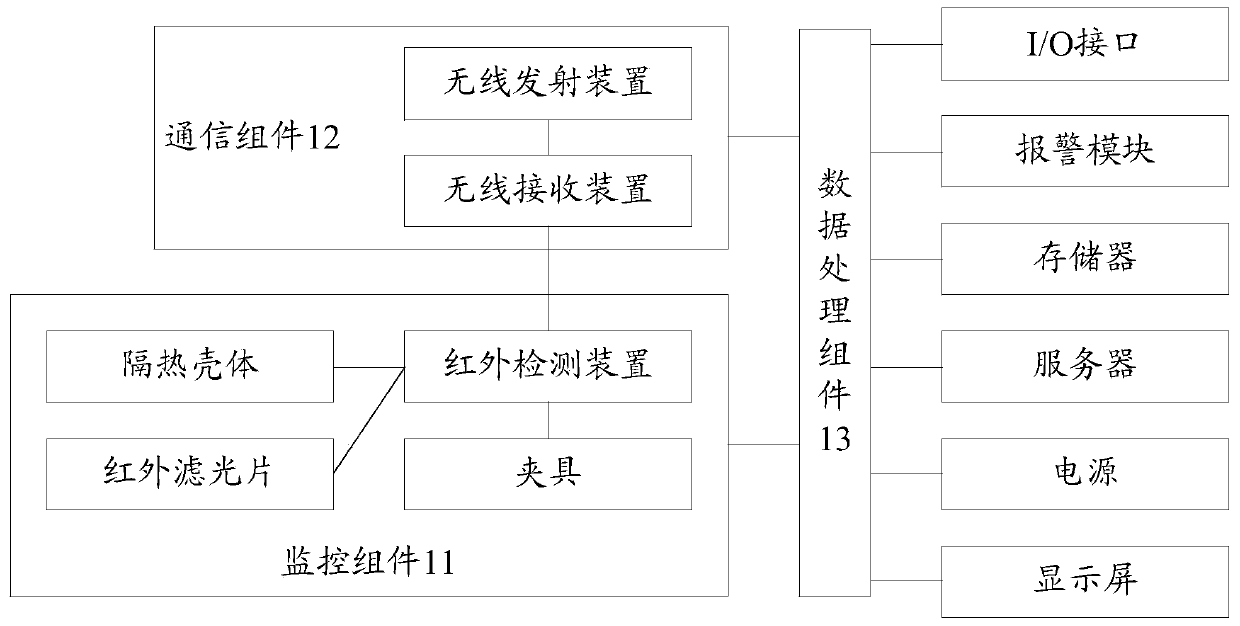

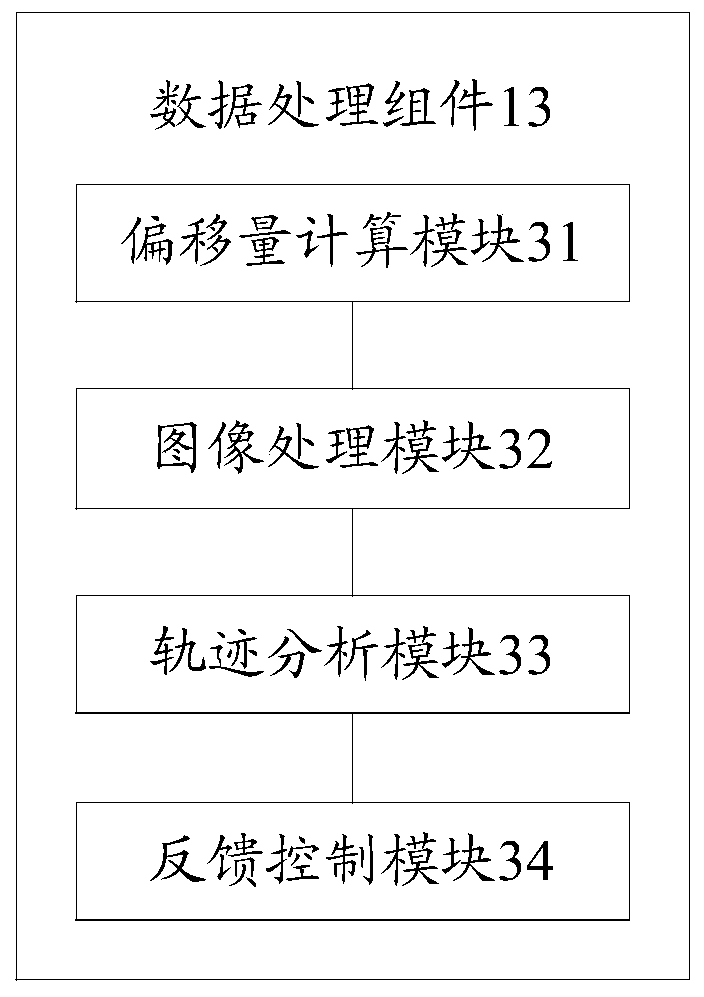

[0042] like figure 1 As shown, it is a weld track monitoring system provided by the embodiment of this specification, the system includes: a monitoring component 11, a communication component 12 and a data processing component 13, and the communication component 12 is connected to the monitoring component 11 and the data processing component 13 respectively The monitoring assembly 11 includes an infrared detection device, and when the welding position is welded, the infrared detection device is used to collect the infrared image of the weld in the welding process; the communication assembly 12 is used to send the infrared image of the weld to the data processing Component 13; the data processing component 13 is used to determine the actual weld centerline trajectory in the welding process according to the weld infrared image and the target weld centerline trajectory, and compare the actual weld centerline trajectory with the target weld The center line trajectory is compared t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com