Adjustable welding head device

A welding head and adjustable technology, which is applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of unfavorable staff working for a long time, unfavorable improvement of welding work efficiency, and affecting the health of staff, so as to achieve convenient welding Good operation, practicality, and strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

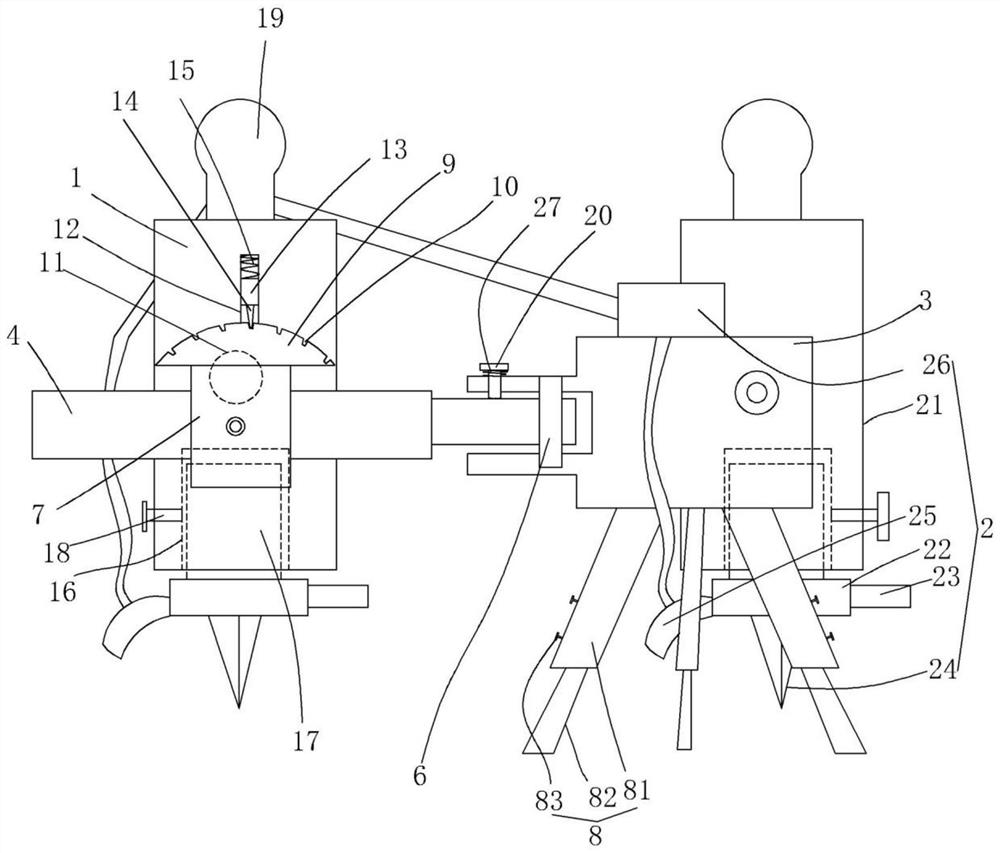

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , an adjustable welding head device, including two first welding heads 2 and second welding heads 1 with the same structure, and also provided with a positioning bracket 3 and an adjusting bracket 4, and the adjusting bracket is connected to the On the positioning bracket, the first welding head is fixed on the side of the positioning bracket by the screw rod 6, the second welding head is arranged on the adjusting bracket by the slider 7, and three welding heads are fixed on the bottom surface of the positioning bracket. A telescopic support foot 8 is arranged in a triangle, a semicircular positioning block 9 is fixed on the top surface of the slider, and a buckle slot 10 is evenly opened on the arc edge of the semicircular positioning block. The side part of the second welding head is connected on the describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com