Curved-surface self-adaptive clamp for laser welding of spatial curved surface fan blade

A technology of laser welding and fan blades, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

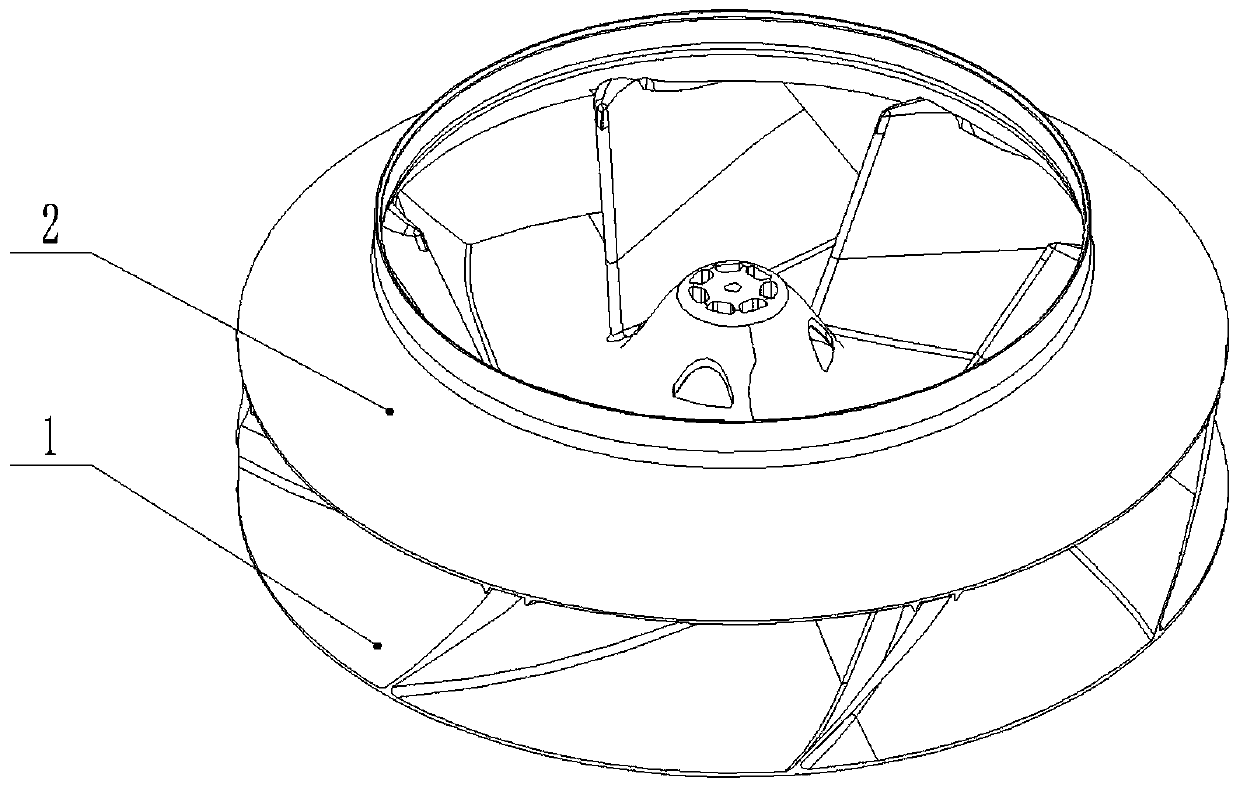

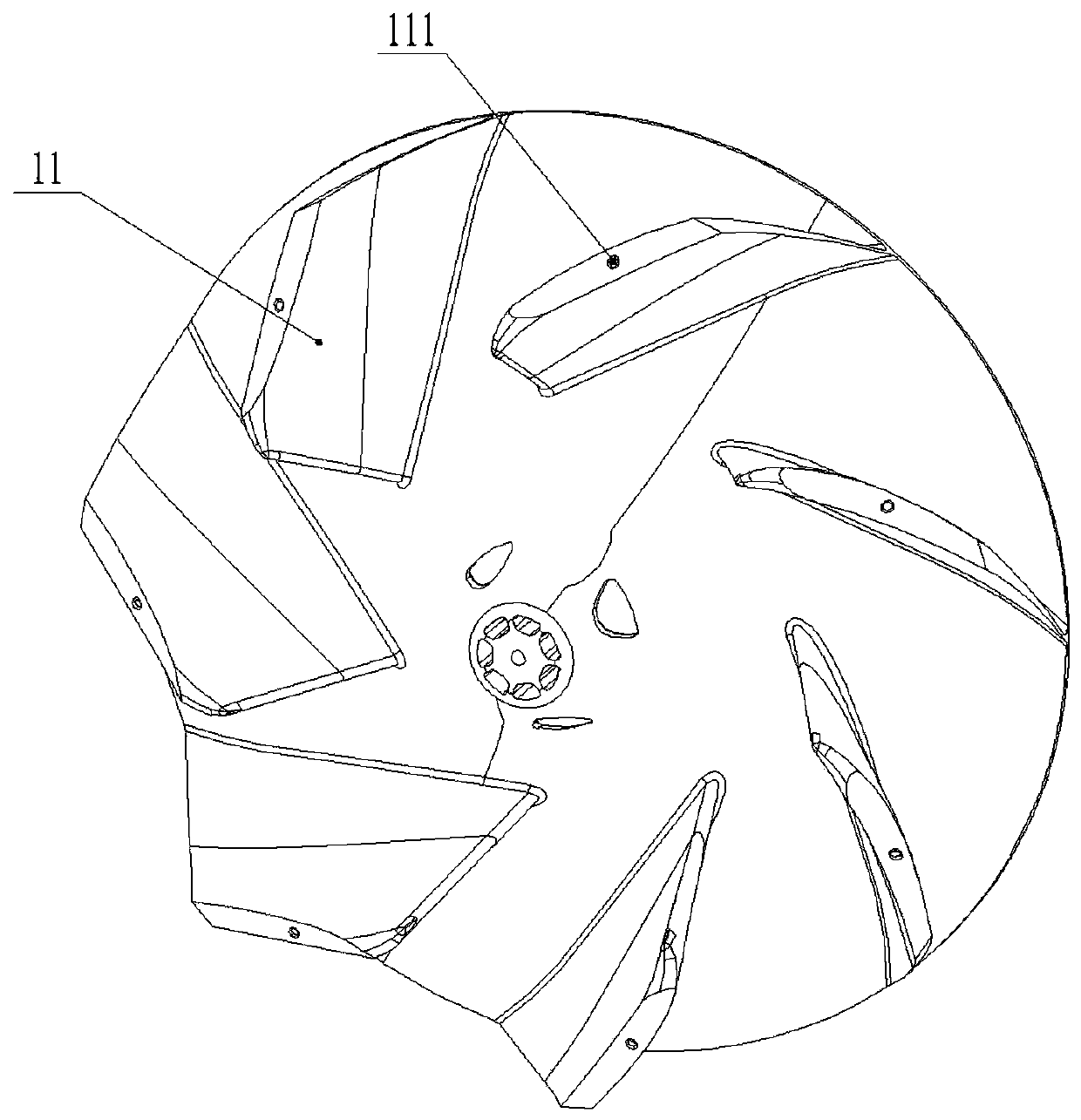

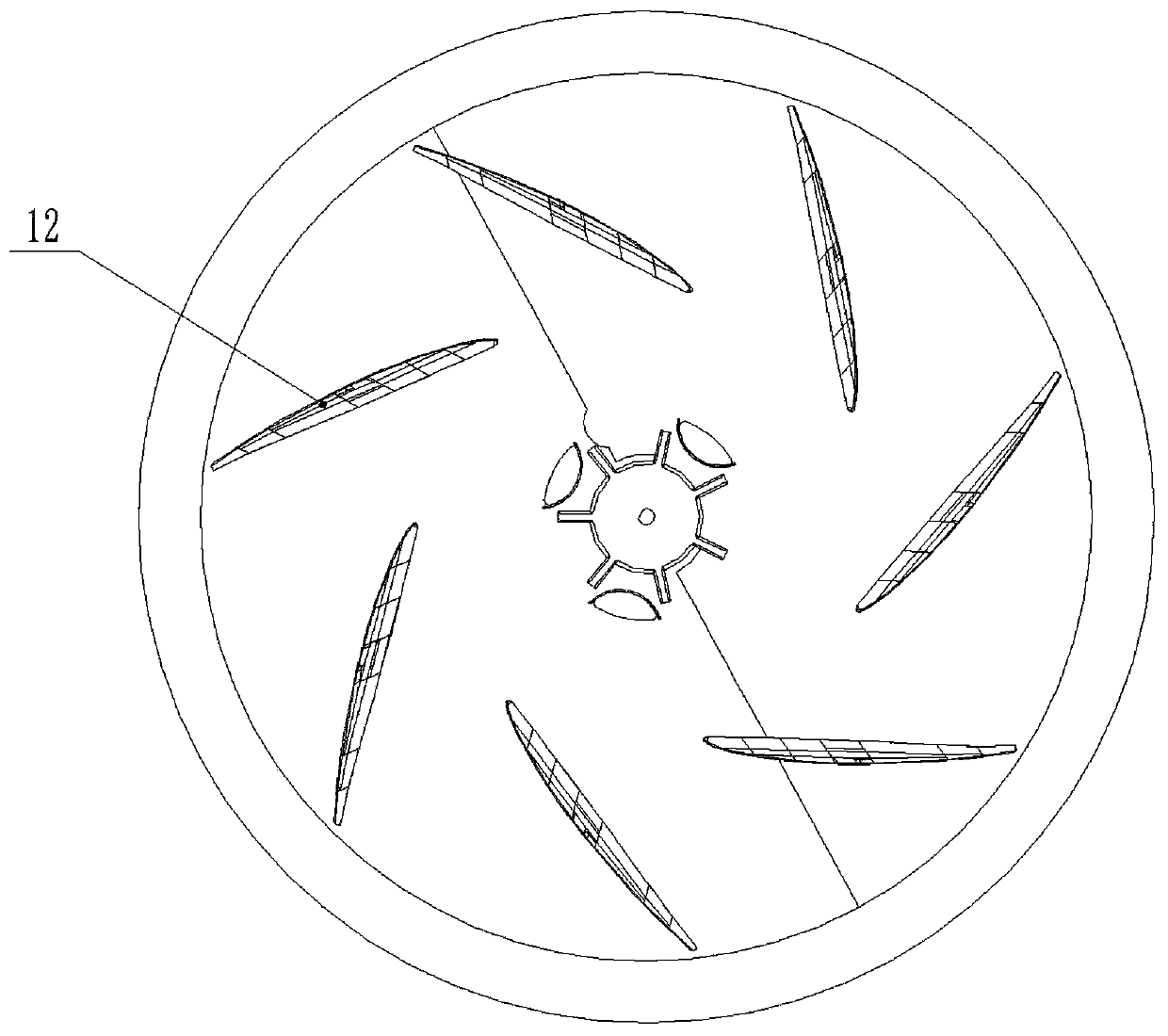

[0029] Below to Figure 1 to Figure 5 The structure of the space surface fan blade shown is taken as an example to illustrate the application of the self-adaptive fixture.

[0030] combine Figure 1 to Figure 5 As shown, the workpiece space curved surface fan blade of this embodiment has seven blades 11 in the base body 1, positioning grooves 12 are located on the bottom surface of the base body 1 corresponding to the positions of each blade, and the bottom surface of the air guiding ring 2 corresponds to each blade There is a profiling groove 21 matching the shape of the upper end of the blade at the connecting position, the matching surface in the profiling groove has a positioning cone pin 22, and the matching surface of the upper end of each blade 11 and the air guide ring 2 has a positioning cone pin 22 matching. The positioning taper hole 111, through the cooperation of the positioning taper pin 22 and the positioning taper hole 111, the wind guide ring and the blade ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com