Three-direction posture adjustment combined engine butting assembly device

An assembly device and engine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that cannot meet the requirements of synchronous and accurate docking of combined engines, and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments.

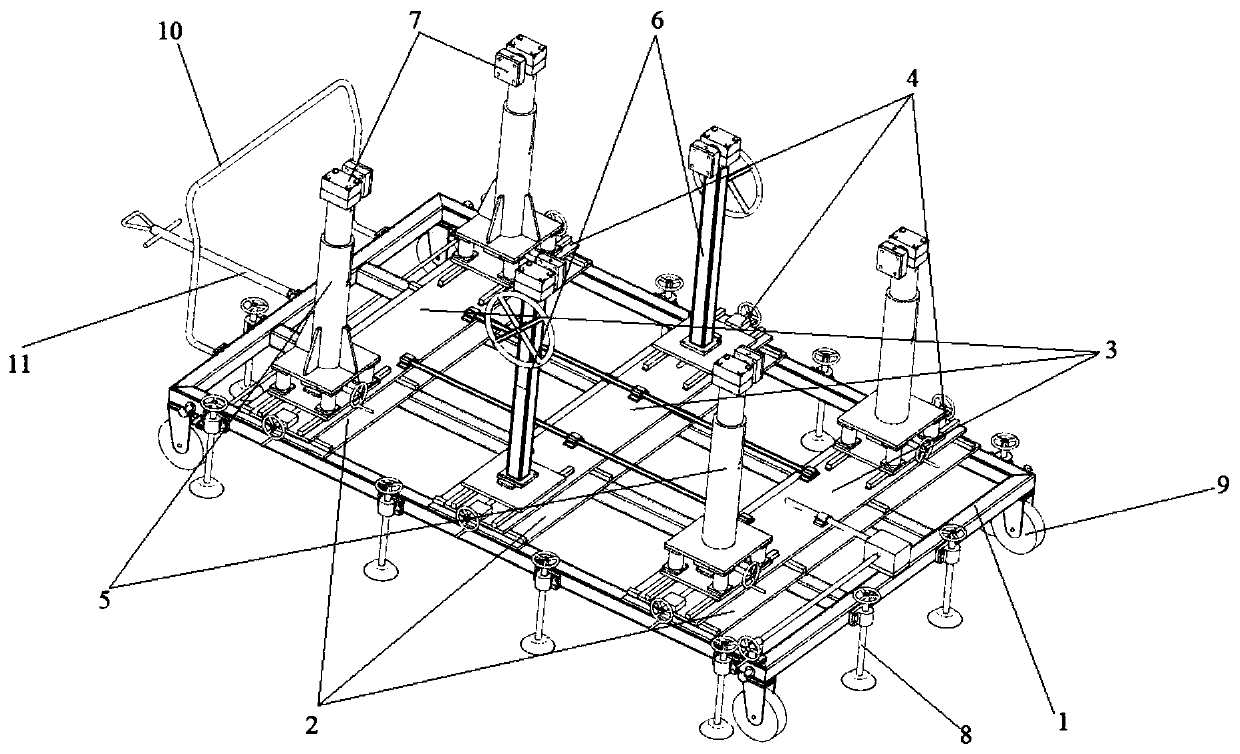

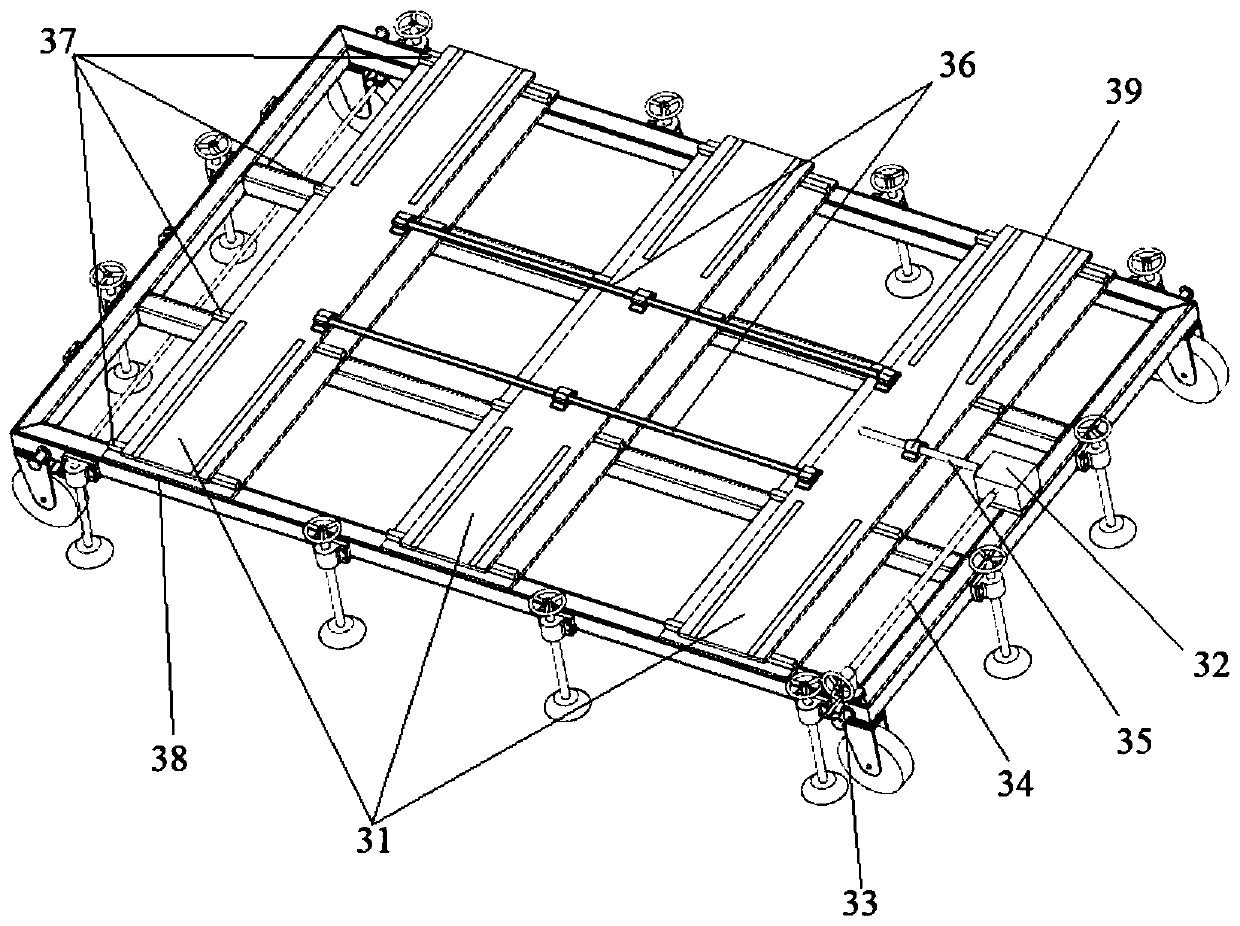

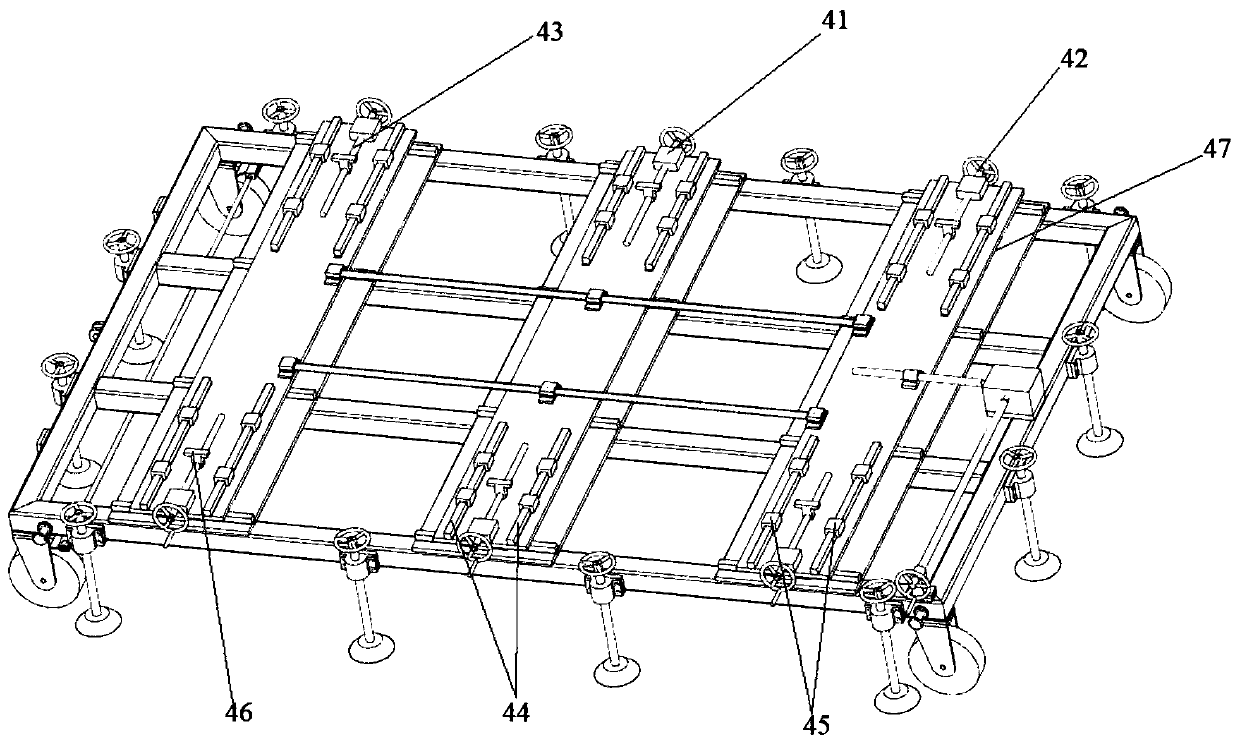

[0028] A combined engine docking assembly device for three-way attitude adjustment, the device includes a frame 1, a connecting plate 2, an X-direction moving mechanism 3, a Y-direction moving mechanism 4, a Z-direction lifting mechanism 5, a Z-direction follow-up mechanism 6, a ball Head connecting structure 7, supporting structure 8, universal casters 9, handle 10 and traction mechanism 11, wherein the frame 1 is a rectangular structure, the connecting plate 2 is uniformly fixed along the width direction of the frame 1, and each connecting plate 2 is respectively provided with X X-direction moving mechanism 3, and each connecting plate 2 is equipped with X guide rail 37, and X-direction moving mechanism 3 cooperates with corresponding X-direction guide rail 37 respectively; X-direction moving mechanism 3 includes X-direction base plate 31, each X-direction Both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com