3D flexible interior trim component and foaming system thereof

A foaming system and flexible technology, applied in the field of face cover and seat foam, can solve the problems of poor stability and difficult to meet the individual needs of users, and achieve the effect of ensuring integrity, excellent exterior decoration effect and stable shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

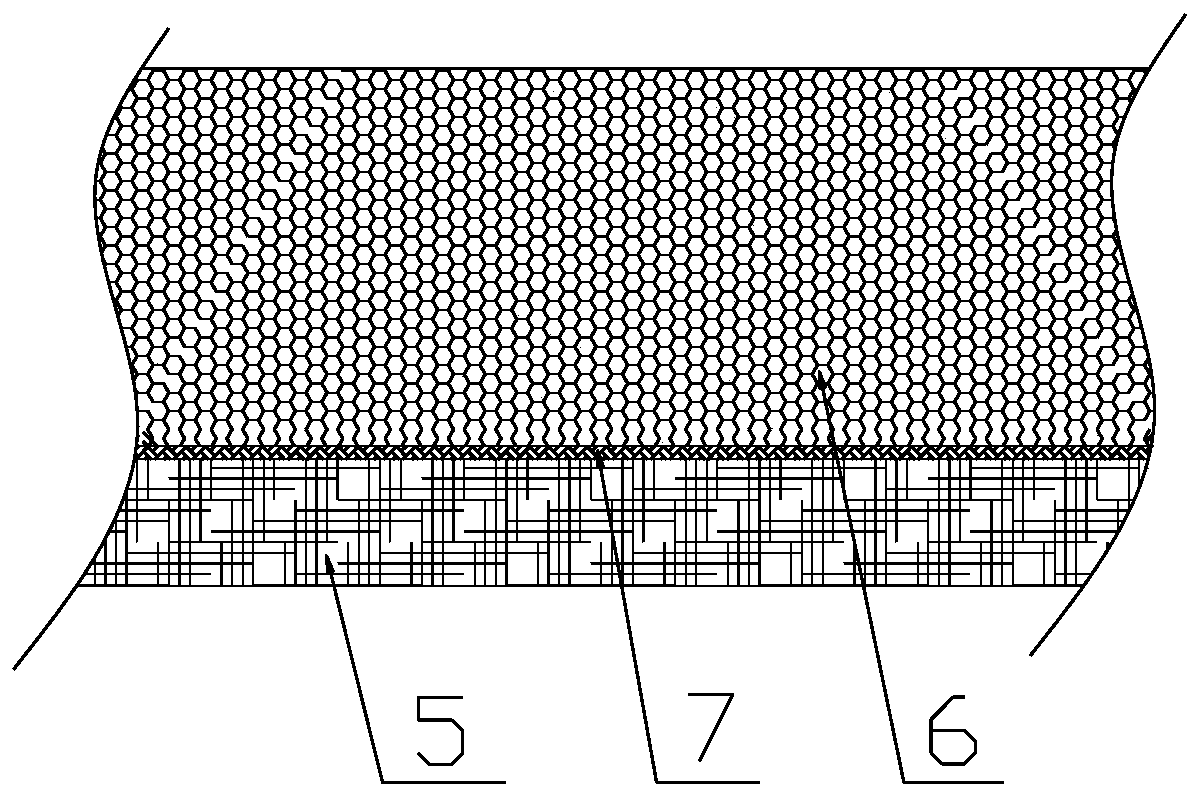

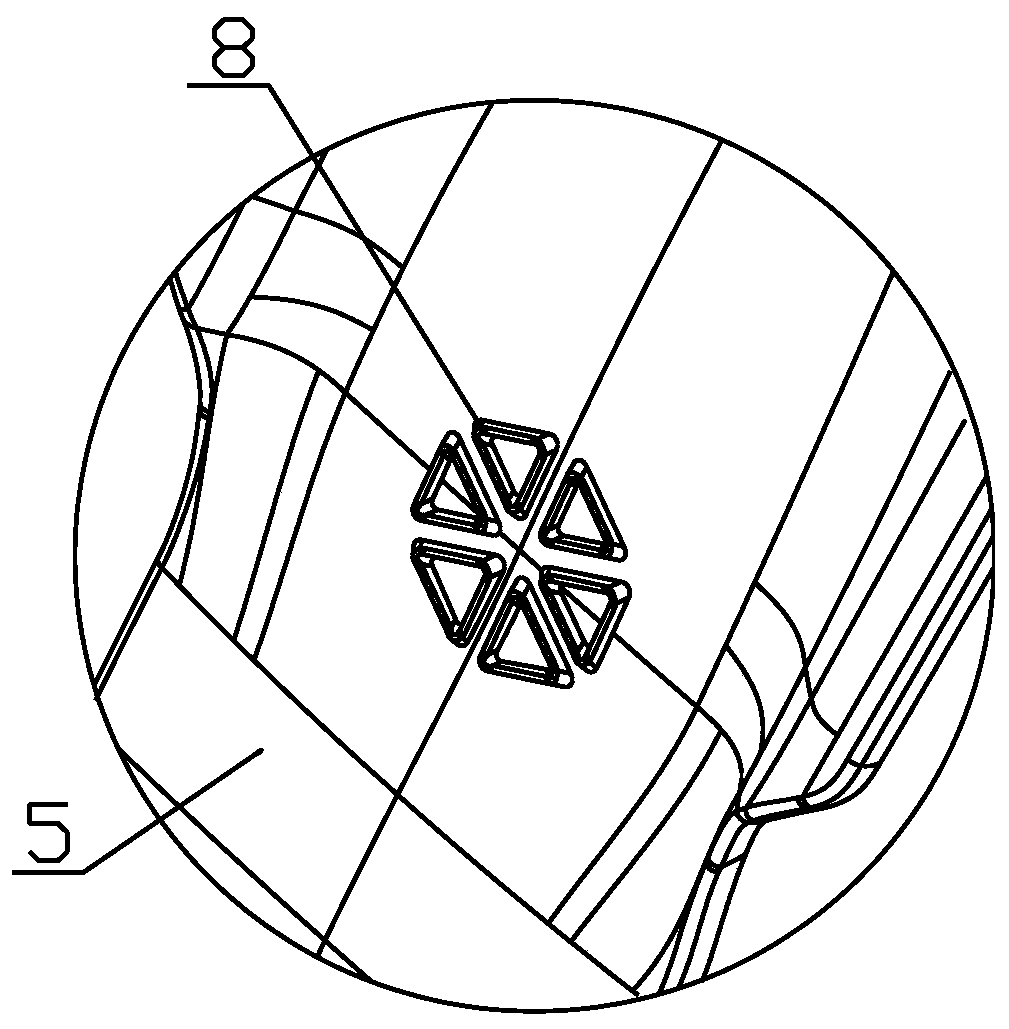

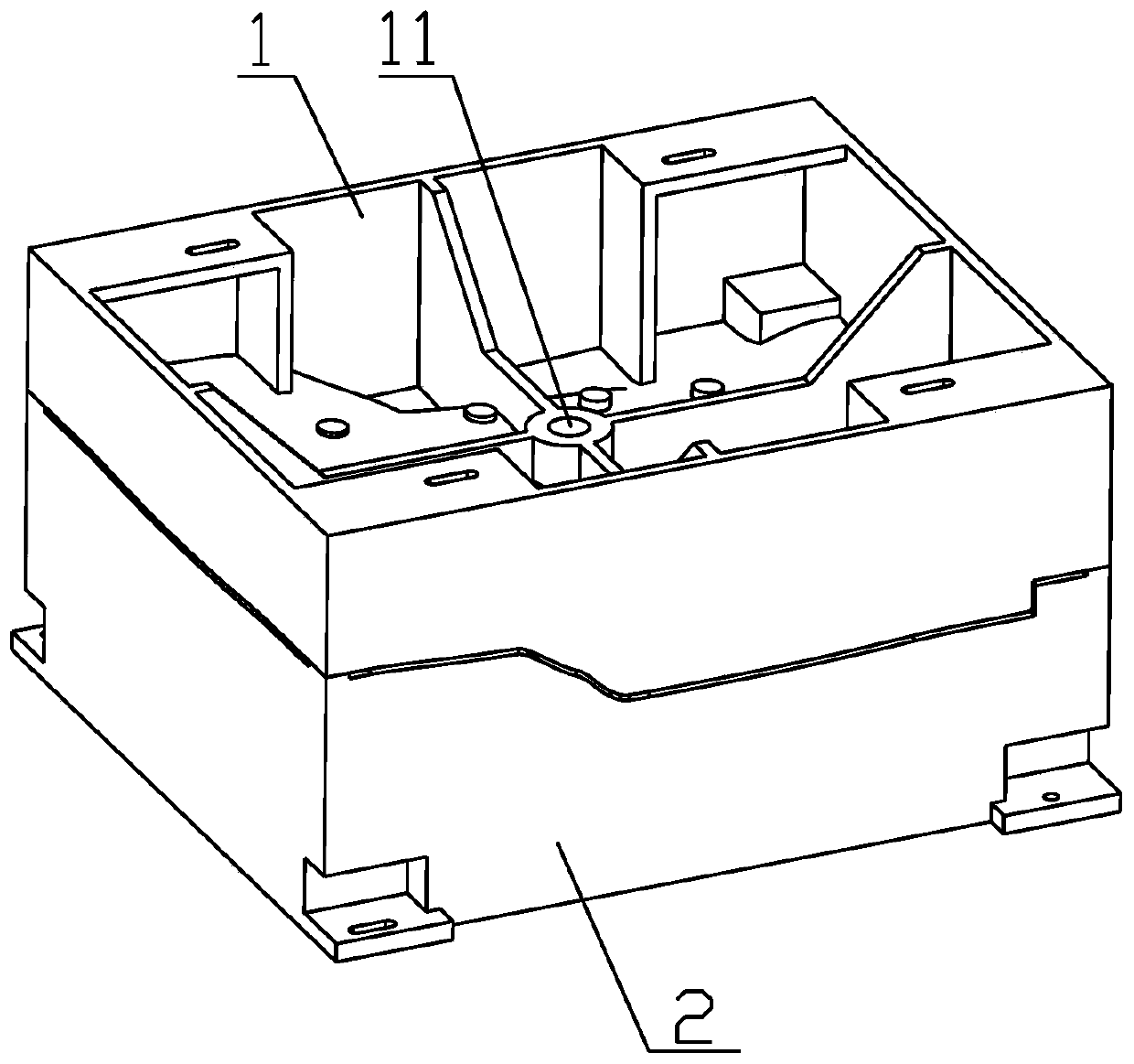

[0031] refer to figure 1 and figure 2 The 3D flexible interior parts shown, taking the 3D cover as an example, mainly include a surface layer 5 and a foam layer 6, and the surface layer 5 is a layer in direct contact with the human body, using soft leather, cloth (fabric), PVC etc., the foam layer 6 is mainly used to form a 3D three-dimensional shape 8 on the side close to the surface layer 5, and through the surface layer to form a three-dimensional contour on the surface of the cover, it will be displayed on the seat surface to meet individual design requirements, and The foam molding can relatively prolong the stability of the three-dimensional modeling 8 pattern, which is durable and not easily deformed, and there is no suture on the surface of the cover.

[0032] In addition, in this application, the foam layer 6 is combined with the surface layer 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com